Perovskite-type light-sensitive material in cubic system structure and preparation method therefor

A technology of perovskite material and cubic crystal system, which is applied in the field of solar cells, can solve the problems of poor stability and low optical absorption rate, and achieve the effects of improving stability, enhancing light absorption, and easily forming thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

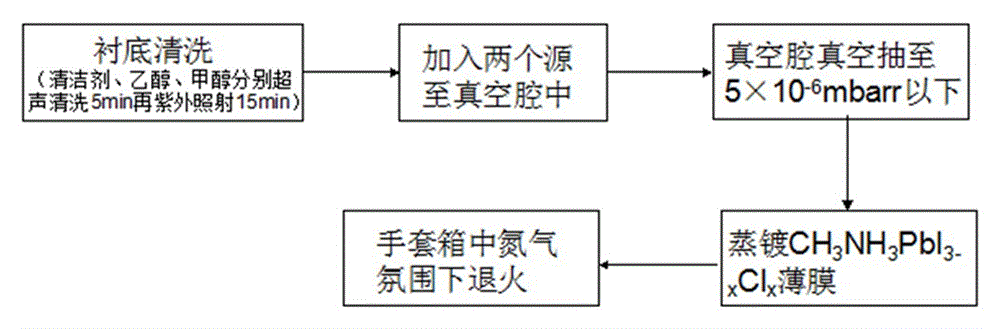

[0041] A method for preparing a perovskite solar cell, comprising the steps of:

[0042] 1) Pretreat the substrate. Pretreatment method: clean the substrate with detergent, then ultrasonically clean it with absolute ethanol and methanol respectively for 5 minutes, and then irradiate it with ultraviolet lamp or ozone for 15 minutes. The substrate is fixed on the evaporation bracket, and then placed in the evaporation chamber. Before the substrate is placed in the alumina crucible, the substrate needs to be pre-baked and preheated in the evaporation chamber, and then Carry out thermal insulation evaporation, put two alumina crucibles carrying different evaporation sources into the evaporation chamber, and the evaporation sources are respectively CH 3 NH 3 I. PbCl 2 ;

[0043] 2) Heating two alumina crucibles, and keeping CH throughout the heating process 3 NH 3 I and PbCl 2 The molar ratio is 3:1, and the vacuum in the evaporation chamber is pumped to 5×10 -6 Below mbar, ...

Embodiment 2

[0048] A method for preparing a perovskite solar cell, comprising the steps of:

[0049] 1) Pretreat the substrate. Pretreatment method: clean the substrate with detergent, then ultrasonically clean it with absolute ethanol and methanol respectively for 5 minutes, and then irradiate it with ultraviolet lamp or ozone for 15 minutes. The substrate is fixed on the evaporation bracket, and then placed in the evaporation chamber. Before the substrate is placed in the alumina crucible, the substrate needs to be pre-baked and preheated in the evaporation chamber, and then Carry out thermal insulation evaporation, put two alumina crucibles carrying different evaporation sources into the evaporation chamber, and the evaporation sources are respectively CH 3 NH 3 I. PbCl 2 ;

[0050] 2) Heating two alumina crucibles, and keeping CH throughout the heating process 3 NH 3 I and PbCl 2 The molar ratio is 3:1, and the vacuum in the evaporation chamber is pumped to 5×10 -6 Below mbar, ...

Embodiment 3

[0055] A method for preparing a perovskite solar cell, comprising the steps of:

[0056] 1) Pretreat the substrate. Pretreatment method: clean the substrate with detergent, then ultrasonically clean it with absolute ethanol and methanol respectively for 5 minutes, and then irradiate it with ultraviolet lamp or ozone for 15 minutes. The substrate is fixed on the evaporation bracket, and then placed in the evaporation chamber. Before the substrate is placed in the alumina crucible, the substrate needs to be pre-baked and preheated in the evaporation chamber, and then Carry out thermal insulation evaporation, put two alumina crucibles carrying different evaporation sources into the evaporation chamber, and the evaporation sources are respectively CH 3 NH 3 I. PbCl 2 ;

[0057] 2) Heating two alumina crucibles, and keeping CH throughout the heating process 3 NH 3 I and PbCl 2 The molar ratio is 3:1, and the vacuum in the evaporation chamber is pumped to 5×10 -6 Below mbar, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com