Sn-C composite material with high N content of lithium battery cathode and preparation method of Sn-C composite material

A technology of composite materials and lithium batteries, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of low conductivity of coated carbon, limited capacity retention capacity, and complicated methods of carbon coating materials, so as to improve conductivity, The effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

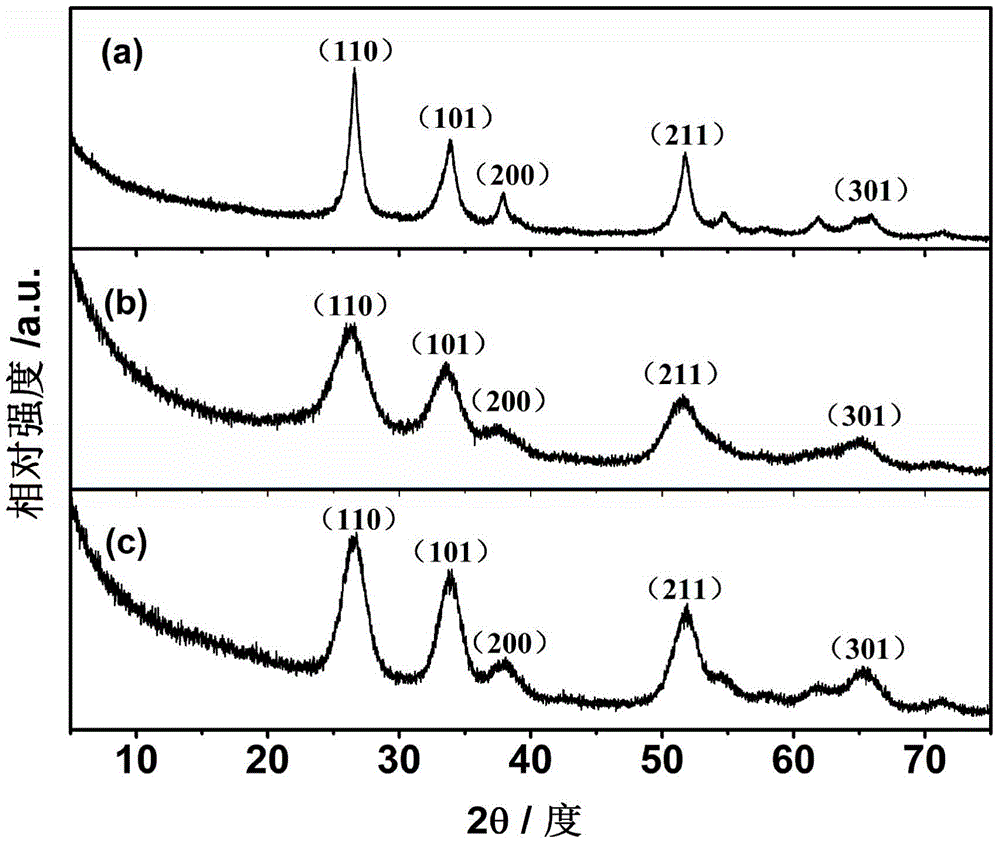

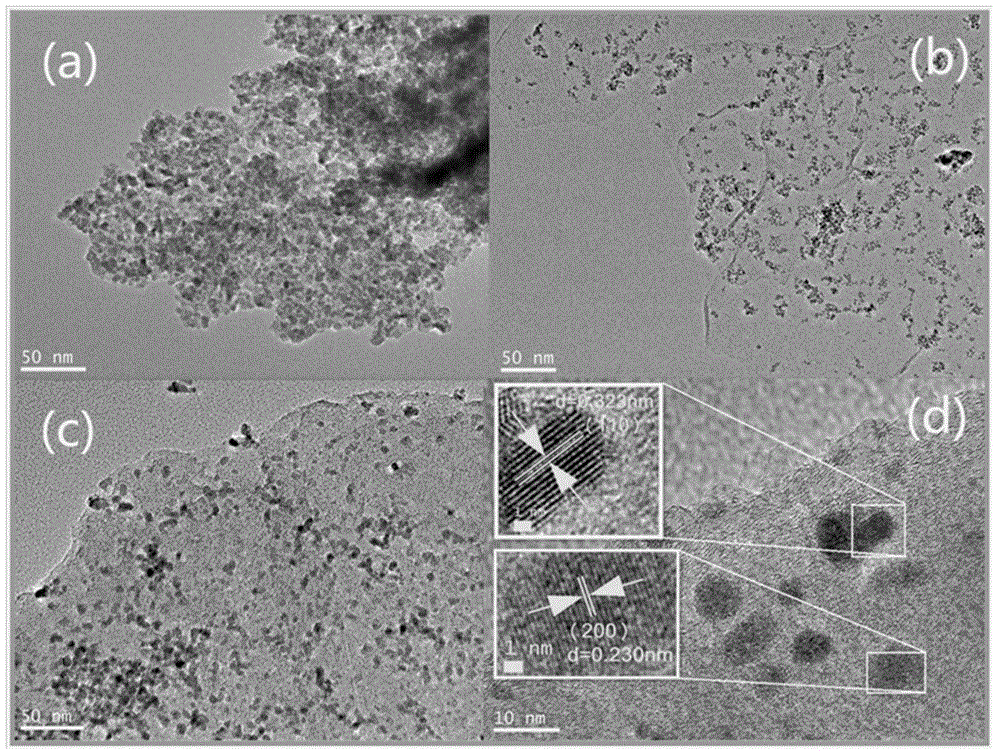

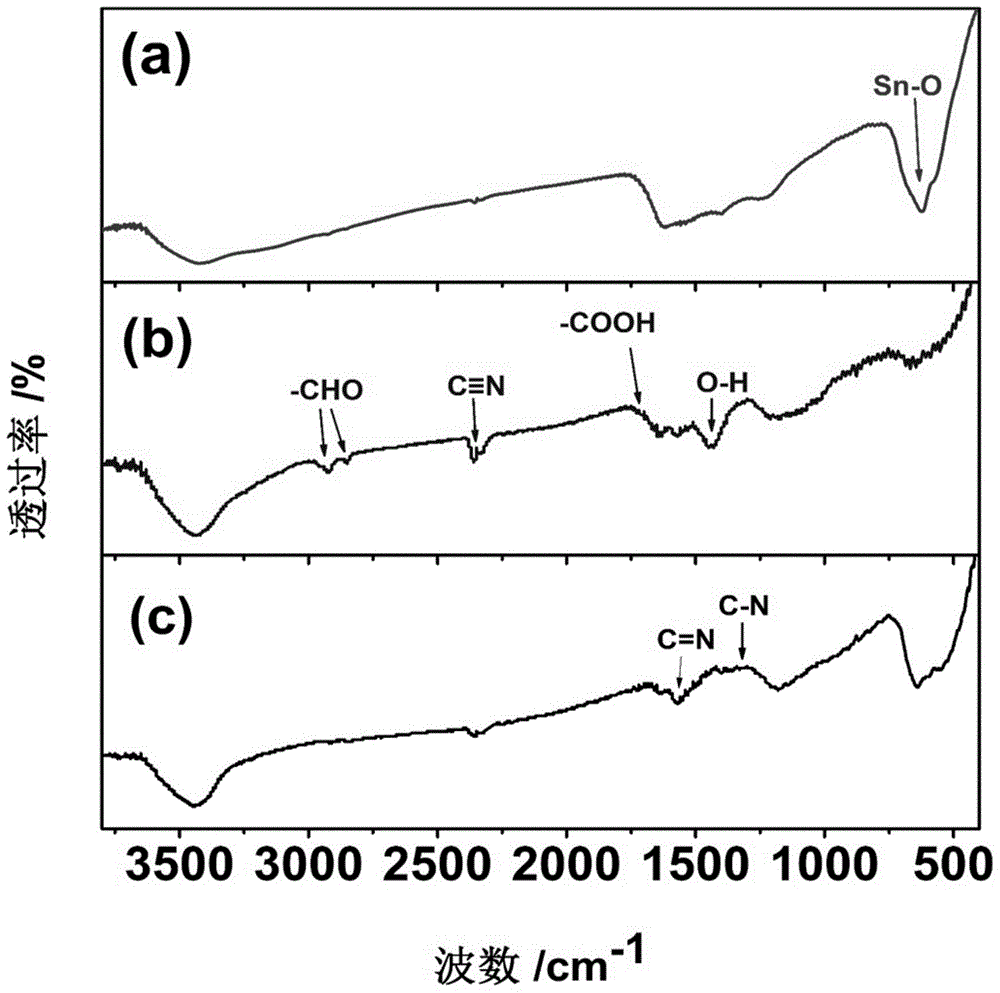

Embodiment 1

[0031] Firstly, graphite oxide was synthesized by optimized Hummers method using graphite powder. 200 mg of graphite oxide was ultrasonically dispersed in 200 ml of distilled water for 2 hours to form a graphene oxide solution, and the obtained solution was marked as solution A. Heat solution A to 45° C., slowly add 0.80 g of diaminomaleonitrile under stirring to fully dissolve it, and the obtained solution is designated as solution B. With stirring, 1.20g of SnCl 4 ·5H 2 O is dissolved in solution B above. Then, the mixed liquid was transferred to a hydrothermal kettle, and hydrothermally heated at 150° C. for 12 hours. After the reaction, it was cooled to room temperature naturally. The obtained product was centrifuged and washed several times, and the product was dried at 70°C. Finally, in high-purity N 2 SnO can be obtained by calcining at 500°C for 2 hours in a tube furnace under atmosphere. 2 / C x N y / GN composites. Using the same method as above, the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com