A kind of silica reinforced diene rubber

A technology of silica and diene rubber, applied in the field of material processing, to achieve the effect of good minimum adhesive performance, excellent comprehensive performance and low hysteresis loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

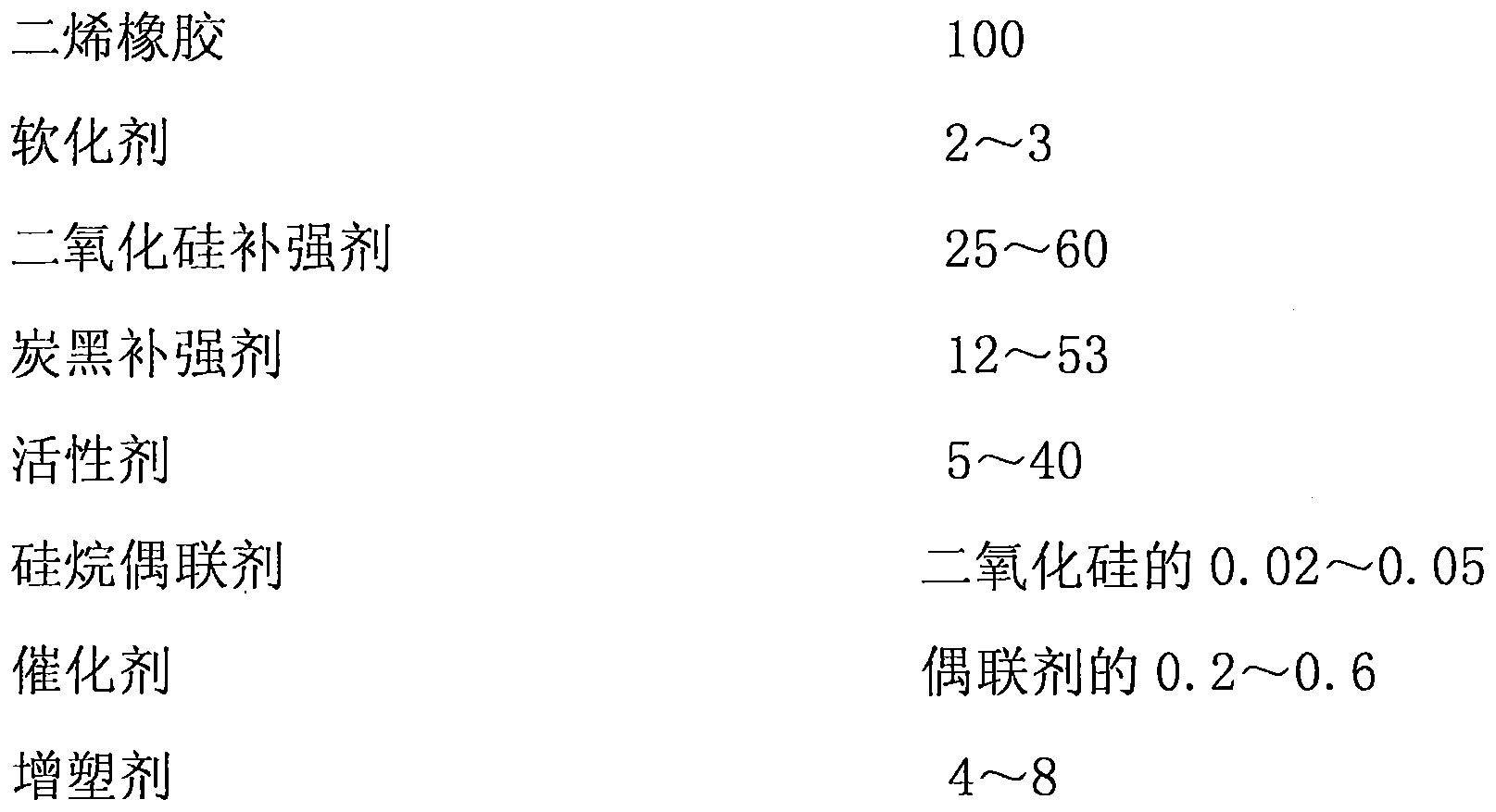

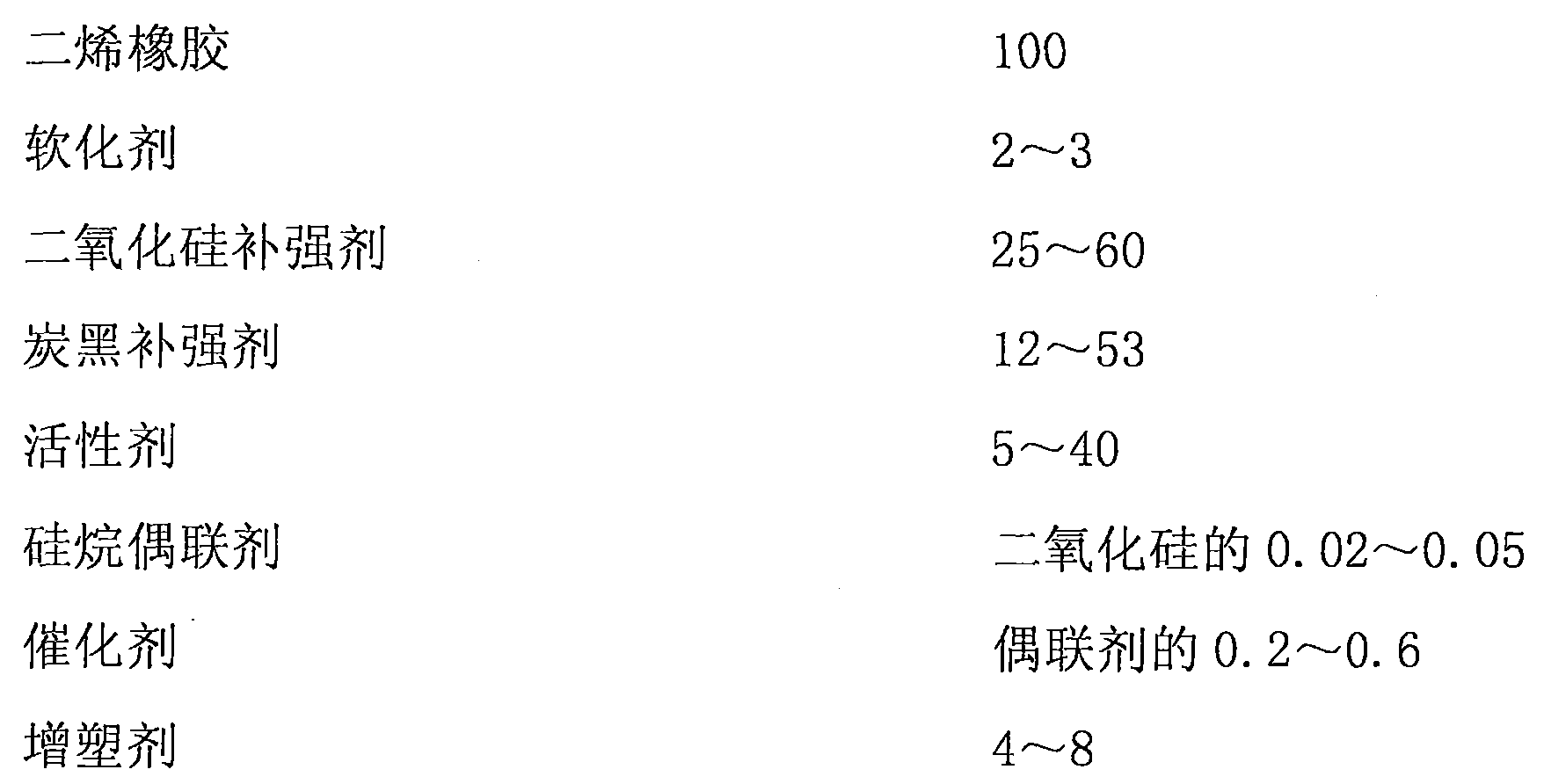

Method used

Image

Examples

Embodiment 1

[0027] A two-step mixing process was adopted. In the non-productive mixing stage, 60 parts of first-grade smoked sheet rubber and 40 parts of emulsion polystyrene-butadiene rubber 1502 were added to the 1L Banbury mixer for 2 minutes; then 3 Parts stearic acid, 5 parts zinc oxide, 8 parts coumarone resin, 25 parts Gr175 precipitated silica, 35 parts N220 carbon black, 1 part bis(3-trialkoxysilylpropyl) tetrasulfide material, 0.5 parts of 2-mercaptobenzothiazole, control the mixing temperature at 130-140°C for 15 minutes; remove the glue (the glue removal temperature is 140°C) and continue mixing on the open mill with cooling water, and the temperature drops to Under 80°C, the sheet is lowered to obtain the masterbatch.

[0028] In the productive mixing stage, an open mill is used. After the masterbatch prepared in the non-productive mixing stage is mixed and rolled on the open mill, 2.0 parts of anti-aging agent 4010NA, 1 part of anti-aging agent RD, 3.0 parts of sulfur, 0.8 ...

Embodiment 2

[0031] The composition of the mixed rubber in the non-productive mixing stage includes: 70 parts of first-class smoked sheet rubber, 30 parts of emulsion polystyrene butadiene rubber 1500, 3 parts of stearic acid, 15 parts of zinc oxide, 6 parts of coumarone resin, 44 parts Gr175 precipitated silica, 12 parts of N220 carbon black, 1.5 parts of bis(3-trialkoxysilylpropyl) tetrasulfide, 0.8 parts of 2-mercaptobenzothiazole.

[0032] The rubber compound components in the production mixing stage include: 2.5 parts of anti-aging agent 4010NA, 1 part of anti-aging agent RD, 2.8 parts of sulfur, 0.6 parts of dimorphine disulfide, 1.0 part of N-cyclohexyl-2-benzothiazole sulfenamide .

[0033] The rubber compound processing technology and sample preparation technology are the same as in Example 1. The tensile strength of vulcanized rubber is 21.4MPa, the 300% modulus is 15.7MPa, the elongation at break is 514%, and the Shore hardness is 78H A , tear strength 90kN / m, resilience 25%, ...

Embodiment 3

[0035] The materials used in the non-productive mixing stage include: 70 parts of first-class smoked sheet rubber, 30 parts of emulsion 1500 styrene-butadiene rubber, 3 parts of stearic acid, 5 parts of zinc oxide, 6 parts of coumarone resin, 49 parts of A380 gas phase method II Silicon oxide, 20 parts of N220 carbon black, 2 parts of bis(3-trialkoxysilylpropyl) tetrasulfide, 0.6 part of 2-mercaptobenzothiazole.

[0036] The ingredients in the production mixing stage include: 2.5 parts of anti-aging agent 4010NA, 1 part of anti-aging agent RD, 3 parts of sulfur, 0.8 part of dimorphine disulfide, and 1.0 part of N-cyclohexyl-2-benzothiazole sulfenamide.

[0037] The rubber compound processing technology and sample preparation technology are the same as in Example 1. The tensile strength of vulcanized rubber is 22.8MPa, the elongation at break is 484%, and the Shore hardness is 77H A , Tear strength 87kN / m, resilience 25%, 100 ℃ hysteresis loss 0.1251, 100 ℃ elastic modulus 19....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com