Method of preparing feed dietary fibers

A technology for dietary fiber and feed is applied in the field of preparing feed dietary fiber, which can solve the problems of environmental pollution, reduce the water holding capacity and swelling property of cellulose products, destroy the physiological characteristics of dietary fiber, etc. Effect of fiber particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

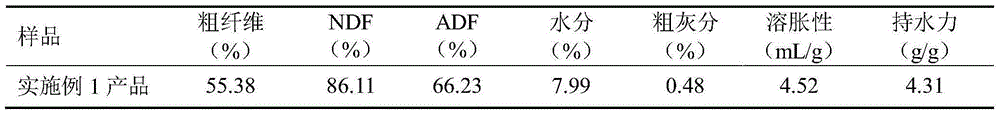

Embodiment 1

[0072] 1) Select one or more of peanut husks, rice husks, corncobs, and bean pods as raw materials for preparing dietary fiber. After cleaning and removing impurities, grind the cellulose raw materials with a universal grinder, pass through a 20-mesh sieve, and add to normal temperature Soak in clean water, the ratio of crushed cellulose raw material to clean water at room temperature is 1g: 20mL, and the soaking time is 24h. Soaking in water can remove some water-soluble impurities (such as soil, dust, water-soluble protein, carbohydrates, etc.), and play a role in improving the purity of dietary fiber products.

[0073] 2) Emulsify the soaked cellulose base material liquid, that is, emulsify the soaked cellulose base material liquid under the condition of 80 MPa for 15 min by using a low temperature and high pressure homogenizer.

[0074] 3) Add α-amylase to the emulsified mixed solution in step 2), adding 1 g of α-amylase with an enzyme activity of 380 U / mg per liter of mix...

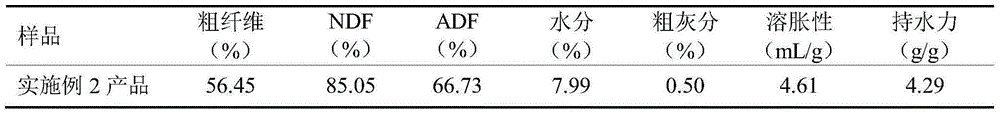

Embodiment 2

[0080] 1) Select one or more of peanut husks, rice husks, corncobs and bean pods as raw materials for preparing dietary fiber. After cleaning and removing impurities, use a universal grinder to crush the cellulose raw materials, pass through an 80-mesh sieve, and add Soak in clean water, the ratio of crushed cellulose raw material to clean water at room temperature is 1g: 10mL, and the soaking time is 12h. Soaking in water can remove some water-soluble impurities (such as soil, dust, water-soluble protein, carbohydrates, etc.), and play a role in improving the purity of dietary fiber products.

[0081] 2) Emulsifying the soaked cellulose base material liquid, that is, using a low temperature and high pressure homogenizer to emulsify the soaked cellulose base material liquid under the condition of 160 MPa for 5 minutes.

[0082] 3) Add α-amylase to the emulsified mixed solution in step 2), adding 1.4 g of α-amylase with an enzyme activity of 380 U / mg per liter of mixed solution...

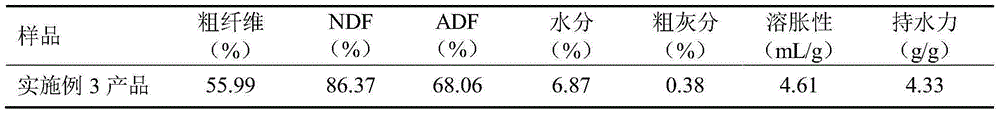

Embodiment 3

[0088] 1) Select one or more of peanut husks, rice husks, corncobs and bean pods as raw materials for preparing dietary fiber. After cleaning and removing impurities, use a universal grinder to crush the cellulose raw materials, pass through a 60-mesh sieve, and add to normal temperature Soak in clean water, the ratio of crushed cellulose raw material to clean water at room temperature is 1g: 40mL, and the soaking time is 20h. Soaking in water can remove some water-soluble impurities (such as soil, dust, water-soluble protein, carbohydrates, etc.), and play a role in improving the purity of dietary fiber products.

[0089] 2) Emulsify the soaked cellulose base material liquid, that is, emulsify the soaked cellulose base material liquid under the condition of 40 MPa for 20 min by using a low temperature and high pressure homogenizer.

[0090]3) Add α-amylase to the emulsified mixed solution in step 2), adding 2 g of α-amylase with an enzyme activity of 380 U / mg per liter of mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Swellability | aaaaa | aaaaa |

| Water holding capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com