Microneedle injection bullet, manufacturing method thereof and mirconeedle injection device

A technology of injection equipment and microneedles, applied in the directions of microneedles, hypodermic injection devices, needles, etc., can solve problems such as difficulty in accurately controlling the dosage of microneedles, inability to solve differences, differences in penetration depth, etc., and achieve precise control The effect of microneedle dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

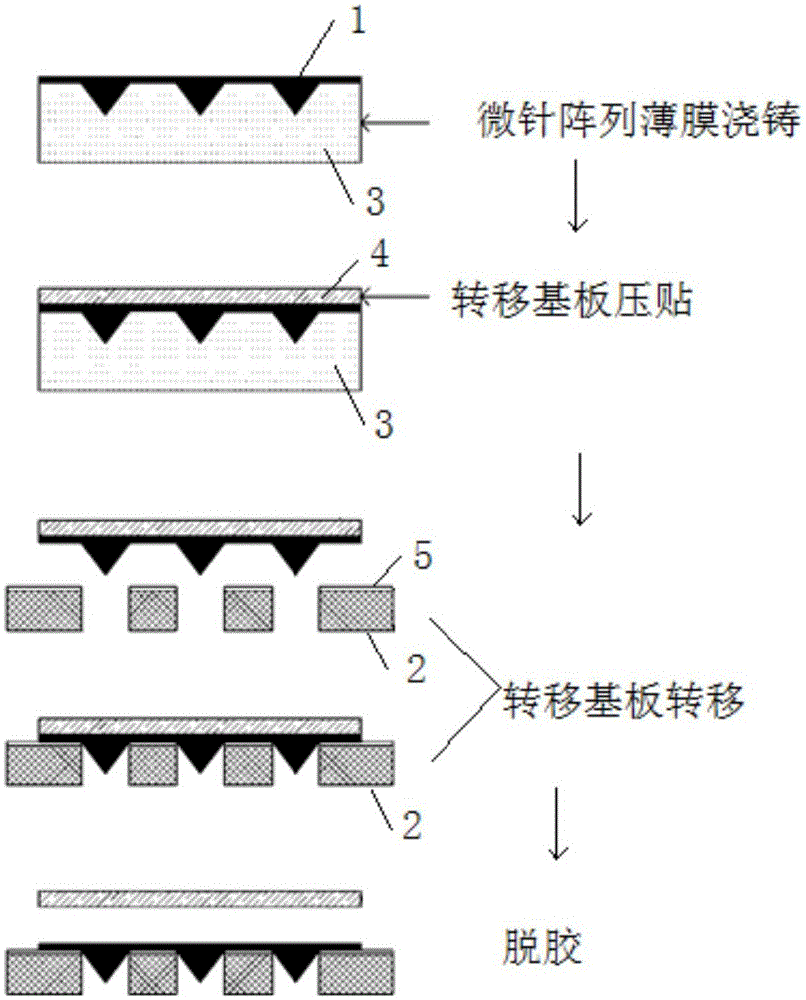

[0038] Such as figure 1 As shown, a microneedle injection bullet includes a microneedle array film 1 and a substrate 2, the microneedle array film 1 includes a film base and a microneedle array on the front side of the film base, and the substrate 2 has an array of through holes aligned with the microneedle array , the film base of the microneedle array film 1 is fixed on the substrate 2, and each microneedle of the microneedle array is inserted into the through holes of the through hole array.

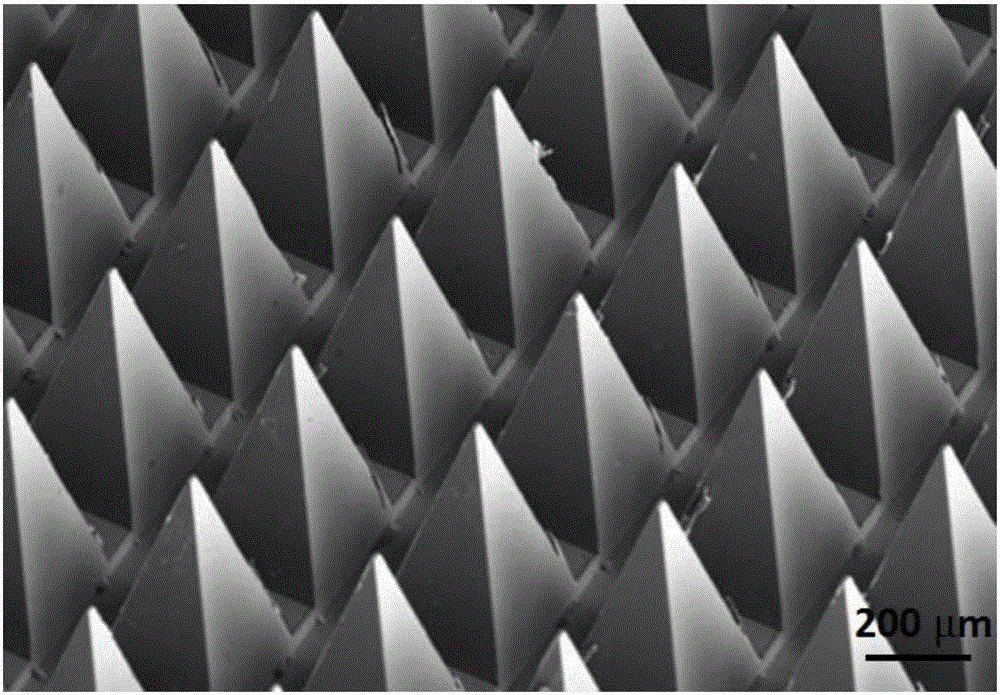

[0039] The microneedles of the microneedle array film 1 are dissolvable microneedles, and the dissolvable microneedles include at least one soluble polymer, which can be selected from silk fibroin, collagen, gelatin, hydrogel, carboxymethyl Cellulose, hydroxypropyl methylcellulose, chondroitin sulfate, glycogen, dextrin, amylose, hyaluronic acid, chondroitin sulfate, polylactic acid-glycolic acid copolymer, polylactic acid-glycolic acid copolymer, poly Ethanol esters, polyvinyl alcoh...

Embodiment 2

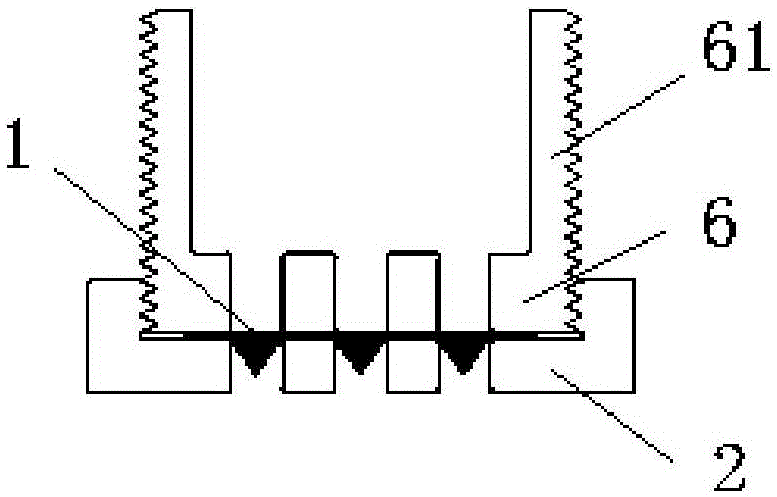

[0056] Such as figure 2 As shown, a microneedle injection bomb, compared with embodiment 1, the microneedle injection bomb also includes a cover plate 6, the cover plate 6 is located on the back of the microneedle array film 1, and the cover plate 6 is connected to the substrate 2 to form a microneedle injection bomb. The shell of the needle array film 1, the connection mode between the cover plate 6 and the substrate 2 is threaded connection or dovetail groove clamping, the microneedle array film 1 is sandwiched between the cover plate 6 and the substrate 2, and the cover plate 6 has a The through-hole arrays on the cover plate 6 and the through-hole arrays on the substrate 2 have the same size, and the through-hole arrays on the cover plate 6 and the substrate 2 are aligned up and down and combined to form a cylindrical array. Each cylinder of ® contains a microneedle like a sandwich.

[0057] There is a connection structure 61 on the cover plate 6 , and the microneedle in...

Embodiment 3

[0065] A kind of microneedle injection equipment, comprises the microneedle injection bomb of embodiment 1 and embodiment 2 and microneedle propulsion device, microneedle injection bomb is installed in the injection port of microneedle propulsion device, and microneedle propulsion device is microneedle propulsion device based on high-pressure gas. Needle propulsion device, the microneedle propulsion device based on high-pressure gas applies high-pressure gas to the back of the microneedle injection bomb, and the high-pressure gas pushes the microneedle away from the microneedle array film 1, presses into the skin, and completely passes through biological barriers, such as skin, tissue Or the cell membrane, the microneedle begins to dissolve the wrapped drug after entering, and the drug completely enters the skin to degrade and absorb, so as to achieve the purpose of precisely controlling the dosage of the microneedle.

[0066] Such as Figure 5 As shown, the microneedle propul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com