Production process of methyl isobutyl ketone

A technology of methyl isobutyl ketone and production process, applied in the field of production technology of methyl isobutyl ketone, can solve the problems of high value, high operating temperature and pressure, waste of energy and materials, etc., so as to reduce the risk coefficients, the effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

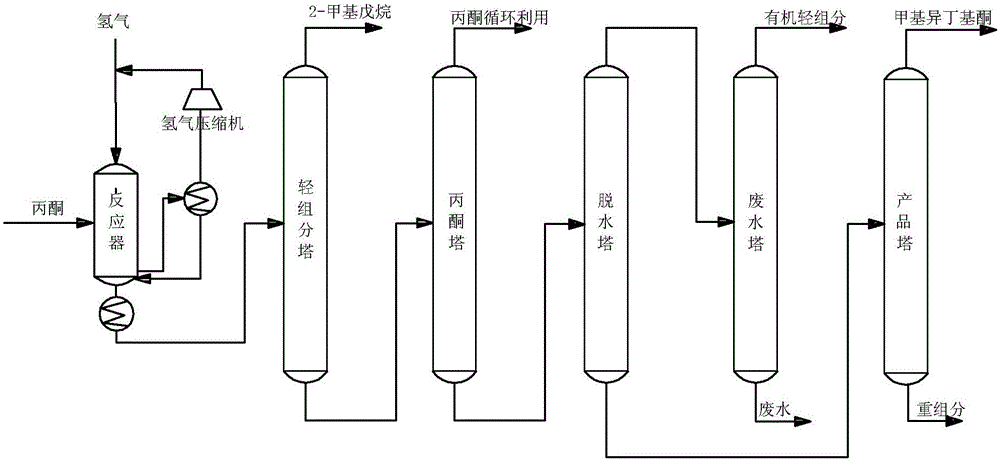

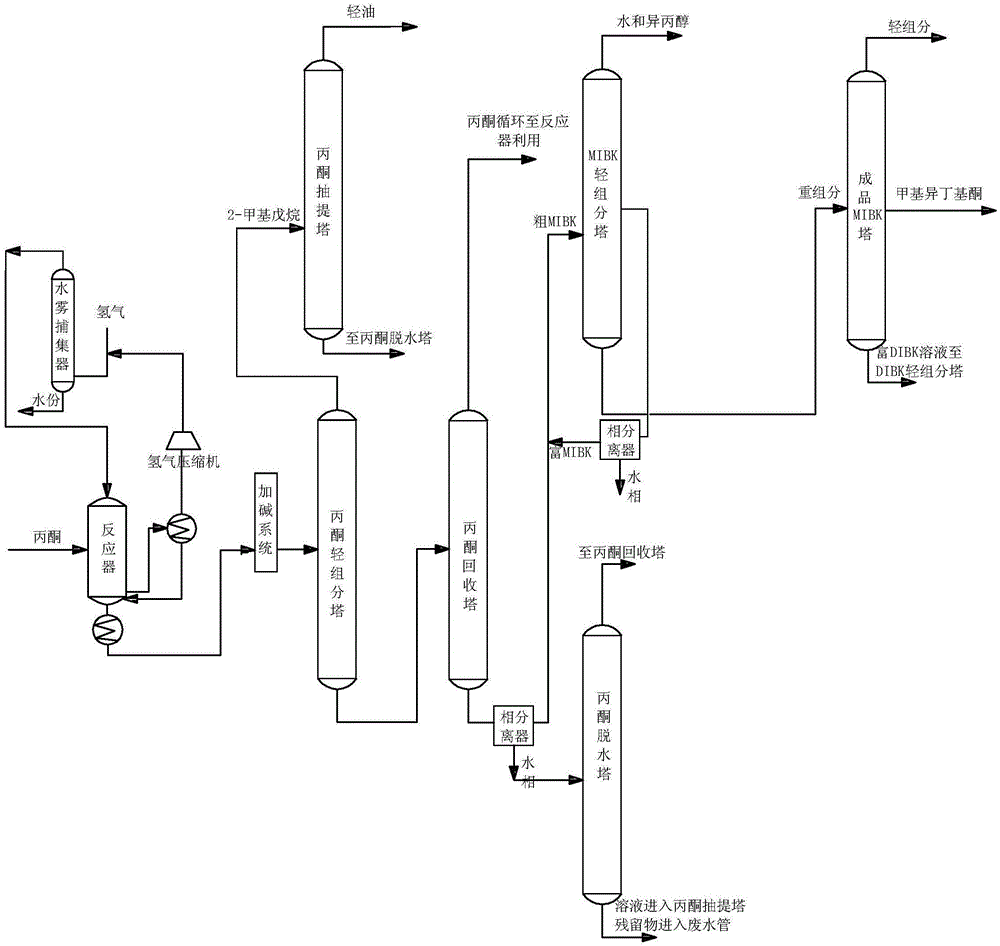

[0018] Reference Figure 1 to Figure 2 Further explanation of the embodiments of the present invention.

[0019] The production process of a methylobaroblatone of the present invention, including the following steps, acetone with a purity of 98.5%is first heated to 90 ° C, and the hydrogen is removed from the hydrogen water fog catcher and then heated with pure preheating with pure preheating.The lattone connection is entered into a fixed bed reactor for reaction, which can increase the concentration of hydrogen in the fixed bed reactor and increase the reaction rate.The fixed bed reactor is equipped with a catalyst with a "strong acidic cationic ion exchange resin" treated by acetate. The reaction temperature is 90 ° C to 120 ° C (excluding 120 ° C), and the reaction pressure is 2.65-3.1MPa.Water cools down the fixed bed reactor, the transformation rate of acetone is greater than 30%, and the selectability of MIBK is greater than 94%. At the same time, it saves a lot of energy, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com