Self-developing polymethacrylate used for bone cement and preparation method for self-developing bone cement

A technology of polymethacrylate and iodohydrin methacrylate is applied in dental preparations, pharmaceutical formulations, dental prostheses, etc. It can solve the problem that non-ionic developer cannot develop for a long time, and achieves prevention of circulation and rapid discharge. , to avoid toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

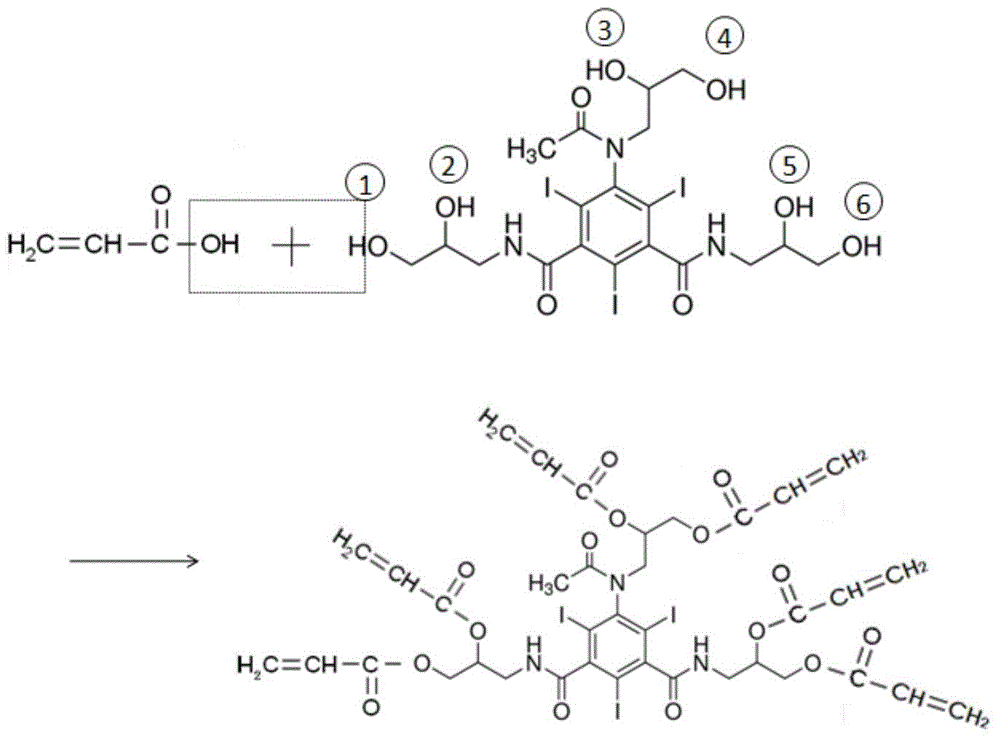

[0041] EDCI: DMAP: methacrylic acid: iohexol ratio is 1.2:0.5:1:2, dissolved in DMF, reacted at 40°C for 2h, washed and dried, concentrated and purified by column chromatography to obtain iodohydrin methacrylate, as Figure 1A shown.

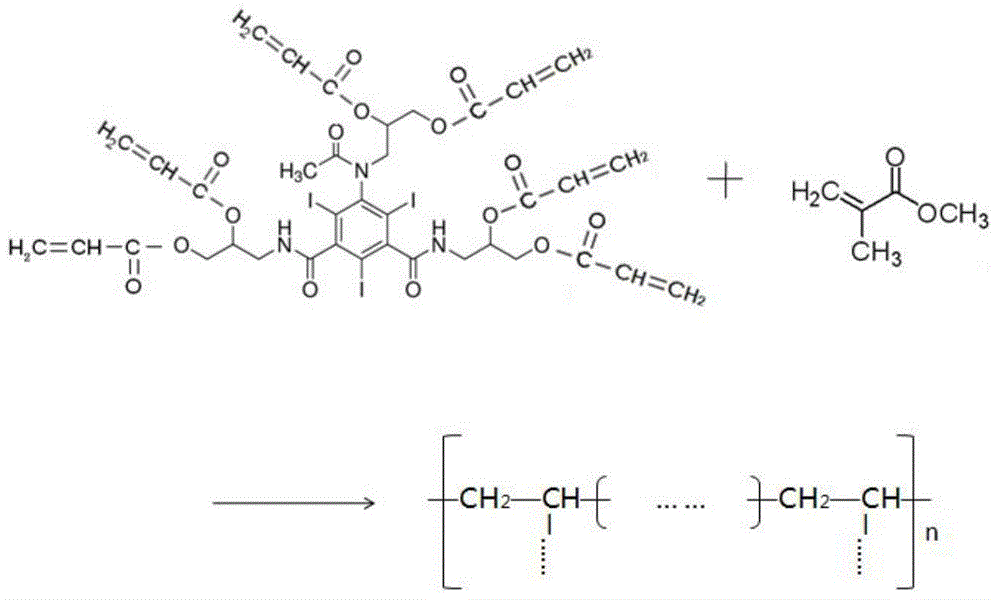

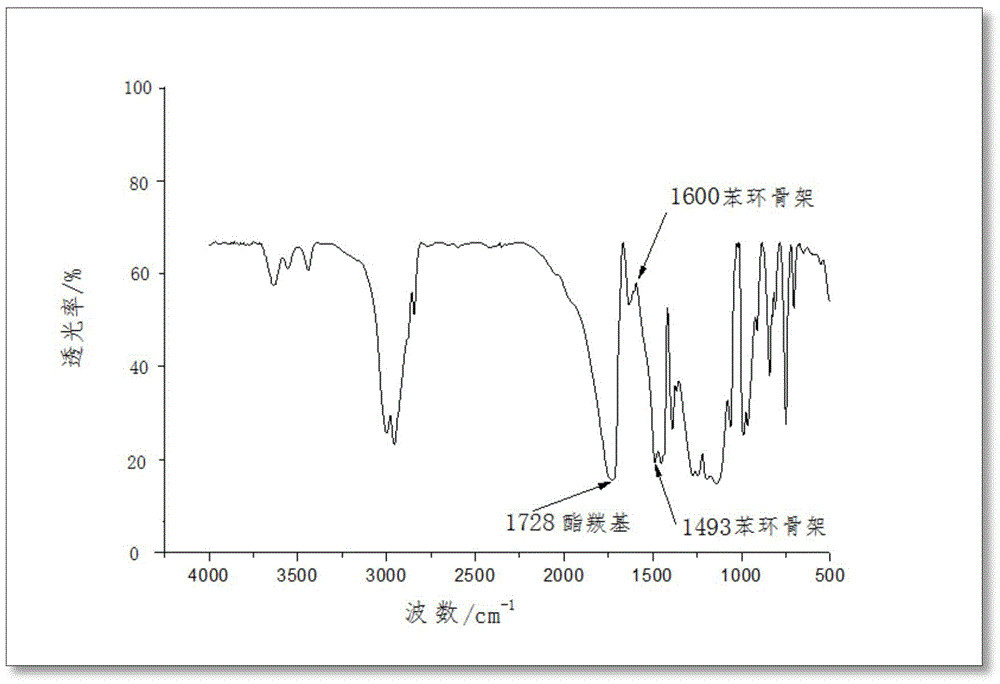

[0042] Prepare purified methacrylate by dissolving in n-hexane, add 0.1% AIBN, 0.002% dodecyl mercaptan as a molecular weight regulator, stir and react at 60°C for 24h, the reaction process is as follows Figure 1B Shown, washed with water, dried and chromatographically purified to obtain self-imaging polyiodomethacrylate. figure 2 The infrared spectrum of self-imaged polyiodomethacrylate can be shown, 1493cm -1 、1600cm -1 The benzene ring skeleton belonging to iohexol appeared at 1710cm -1 A clear ester peak appears. The viscosity-average molecular weight of the self-developing polyiodomethacrylate is about 119,000 according to the calculation of the viscosity method.

[0043] Grind the self-developing polyiodomethacrylate for 2 hours, pas...

Embodiment 5-8

[0050] Example 5-8: Ioversol as a source of developer to prepare self-developing polyiodol methacrylate

[0051] EDCI: tetrabutyl titanate: methacrylic acid: ioversol with a ratio of 1.2:0.5:1:1, dissolved in DMF, reacted at 40°C for 4 hours, washed and dried, concentrated and purified by column chromatography to obtain iodohydrin methacrylate ester.

[0052] Prepare purified methacrylate by dissolving in n-hexane, add 0.1% BPO and 0.002% polythiol as molecular weight regulator, stir and react at 65°C for 24 hours, wash and dry with water, and then chromatographically purify to obtain self-imageable polymethylacrylate Iodooxyacrylate. Viscometry calculation shows that the viscosity-average molecular weight of self-developing polyiodomethacrylate is about 100,000.

[0053] Grind the self-imaged polyiodomethacrylate for 2 hours, pass through a 400-mesh sieve, and carry out refining treatment; take the self-imaged bone cement powder after sieving and BPO, etc. in a mixer, and m...

Embodiment 9-12

[0059] Examples 9-12: Preparation of self-developing polyiodomethacrylate with iodixanol as a source of developer

[0060] DCC: tetraisopropyl titanate: methacrylic acid: iodixanol with a ratio of 1.2:0.5:1:0.1, dissolved in DMF, reacted at 25°C for 4 hours, washed and dried, concentrated and purified by column chromatography to obtain methacrylic acid Iodine esters.

[0061] Prepare purified methacrylate by dissolving it in n-hexane, add 0.2% AIBN and 0.001% polythiol as molecular weight regulator, stir and react at 70°C for 24 hours, wash and dry with water, and chromatographically purify to obtain self-imageable polymethylacrylate Iodooxyacrylate. The viscosity-average molecular weight of self-developing polyiodomethacrylate is about 220,000 through viscosity measurement and calculation.

[0062] Grind the self-developing polyiodomethacrylate for 3 hours, pass through a 400-mesh sieve, and carry out refining treatment; take the sieved self-developing bone cement powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com