Biodegradable medical temperature-sensitive hydrogel and preparing method thereof

A temperature-sensitive hydrogel, biodegradable technology, applied in the fields of fine chemicals and materials science, can solve the problems of application limitation and low gel rupture strength, and achieve the effect of improving solubility and strong rupture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention also discloses a method for preparing a temperature-sensitive hydrogel, comprising the following steps:

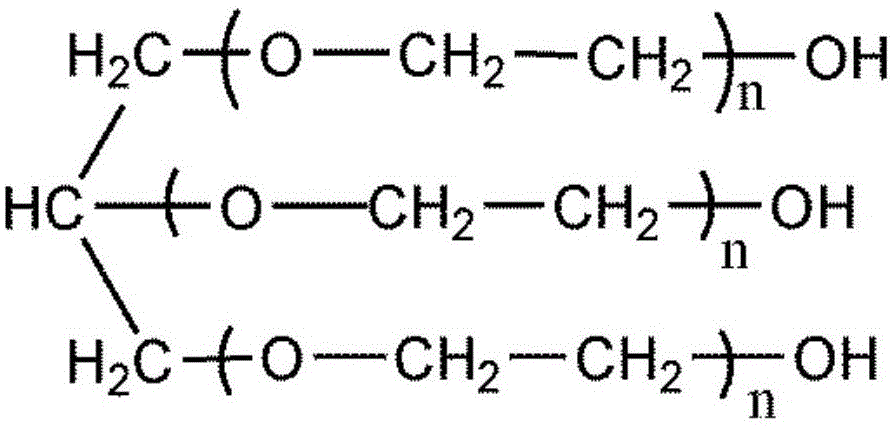

[0034] (1) Mix hydrophilic 3-arm-PEG with lactide and glycolide, and then add a catalyst accounting for 0.05-0.5% of the mass fraction of the mixture. Vacuum first, then nitrogen, then vacuum, repeat 3 times, and finally under the conditions of vacuum degree of 10-30Pa and polymerization temperature of 110-150℃, melt ring-opening polymerization for 12-48h to obtain 3-arm - PEG-PLGA block crude product;

[0035] Wherein the molecular weight of the three-arm polyethylene glycol 3-arm-PEG is 400-50000, PLGA is glycolide and lactide copolymer, and the mass ratio of lactide and glycolide is 2:1-20 : 1, the mass ratio of the mass of the sum of lactide and glycolide to the three-arm polyethylene glycol is 1.2:1~4:1;

[0036] (2) Dissolve the crude product with ice water at 0-5°C, heat up to precipitate solids, the upper limit of temperature rise is 60-80°C,...

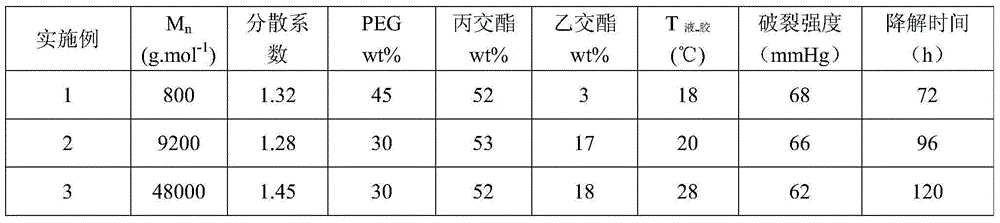

Embodiment 1

[0039] Add 40017.5g of three-armed polyethylene glycol into the round bottom flask, then add 20g of D,L-lactide and 1g of glycolide, and then add 0.02g of stannous octoate as a catalyst. Vacuum first, then feed nitrogen, and then vacuum again, repeat 3 times, and finally react for 48 hours under the conditions of vacuum degree of 10 Pa and polymerization temperature of 110°C.

[0040] The product was dissolved in distilled water at 5°C, heated to 60°C to precipitate the copolymer and the water layer was discarded, and the operation was repeated three times to remove unreacted monomers and low-molecular water-soluble substances. The resulting copolymer was freeze-dried for 48 hours at a freeze-drying vacuum of 1.5 Pa and a temperature of -30°C to obtain a purified 3-arm-PEG-PLGA copolymer with a yield of 87%.

Embodiment 2

[0042] Add 300012g of three-armed polyethylene glycol into the round bottom flask, then add 21g of L-lactide and 7g of glycolide, and then add 0.04g of zinc sulfate as a catalyst. Vacuum first, then feed nitrogen, and then vacuum again, repeat 3 times, and finally react for 24 hours under the conditions of vacuum degree of 30Pa and polymerization temperature of 140°C.

[0043] The product was dissolved in distilled water at 4°C, heated to 80°C to precipitate the copolymer and the water layer was discarded, and the operation was repeated three times to remove unreacted monomers and low-molecular water-soluble substances. The resulting copolymer was freeze-dried for 96 hours at a freeze-drying vacuum of 3 Pa and a temperature of -40°C to obtain a purified 3-arm-PEG-PLGA copolymer with a yield of 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com