Emulsion type anti-adhesive slip agent for powder-free PVC glove coating and preparation method thereof

An emulsion type, slip agent technology, applied in the direction of coating, can solve the problems of affecting the quality of gloves, easy precipitation, sticking back, etc., to achieve the effect of industrial utilization value, simple production method and improved economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A. Preparation of pre-emulsion

[0048] Take 5-40 parts of the synthesized water-based silicon-containing polyurethane, add 20-40 parts of deionized water and 1-5 parts of emulsifier, fully stir for 20-30 minutes, and then add 10-60 parts of methacrylates in turn Monomer, 5-20 parts of acrylate monomer, 0.1-3 parts of diacrylate-type crosslinking agent monomer and 0.5-5 parts of hydrophilic monomer are fully stirred and emulsified to prepare a pre-emulsion.

[0049] B. Seed Preparation of Compound Emulsion

[0050] Add 10-20 parts of water-based silicon-containing polyurethane, add 40-60 parts of deionized water and 1-5 parts of emulsifier, add 10-20 parts of pre-emulsion after stirring, and add 1-2 parts of 10% ammonium persulfate , heated to 60 ~ 65 ℃ for 30 ~ 40 minutes, began to drop the remaining pre-emulsion, and began to drop the remaining 8 ~ 10 parts of 10% ammonium persulfate, dripped within 3 ~ 4 hours, and then heated up to 85 The temperature is maintained...

Embodiment 1

[0076] (1) Synthesis of water-based silicon-containing polyurethane

[0077] 33.5 parts of Pol-2356 (hydroxyl value 54~56mg KOH / g, produced by Qingdao Yutian Chemical Industry), 22.4 parts of polysiloxane diol H-Si 2311 (hydroxyl value 40~50mg KOH / g, Degussa Corporation), 1 part of trimethylolpropane (Swedish Pastor Company), 4 parts of dimethylolpropionic acid hydrophilic agent (Swedish Pastor Company), heated to 70 ℃ under full stirring, Add 20 parts of isophorone diisocyanate, heat up to 75~85 ℃ and react for 3~5 hours, then cool down to 50 ℃, add 2 parts of salt-forming agent, form salt for 10 minutes, add 120 parts of deionized water, then immediately Add 3 parts of chain extender, and discharge after 60 minutes of reaction to obtain the desired water-based silicon-containing polyurethane.

[0078] (2) Synthesis of polyacrylate / silicon-containing polyurethane composite emulsion

[0079] A. Preparation of pre-emulsion

[0080] Take 10 parts of the synthesized water-base...

Embodiment 2

[0084] The procedure of Example 1 was repeated, except that 22.4 parts of polysiloxane in Example 1 were replaced with 22.4 parts of POL-2345 (hydroxyl value 54-56 mg KOH / g, produced by Qingdao Yutian Chemical Co., Ltd.) in the synthesis of water-based silicon-containing polyurethane. Alkanediol, others are the same as Example 1.

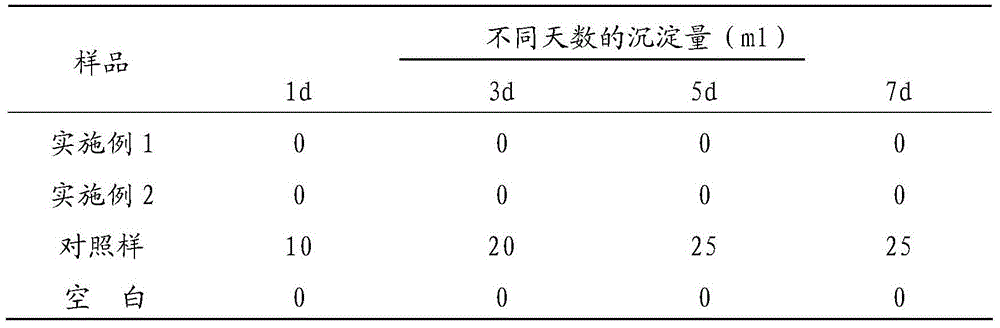

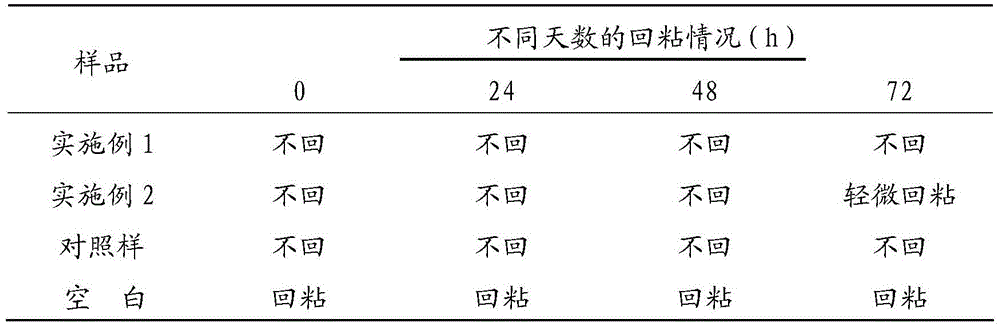

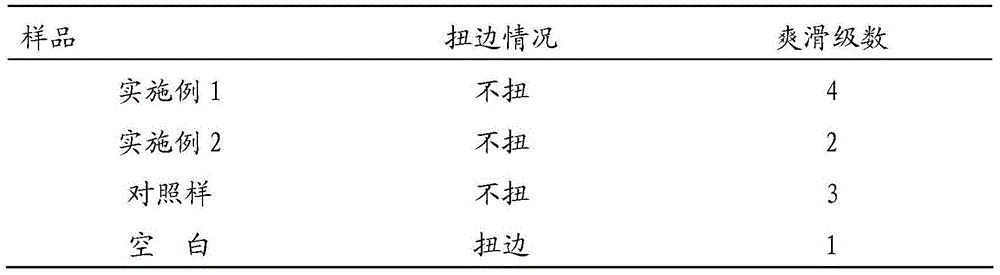

[0085]The polyacrylate / silicon-containing polyurethane composite emulsion prepared by the method of the present invention is prepared according to the following powder-free PVC glove coating formula: 40 parts of water-based aliphatic polyester polyurethane BAYHYDROL110 (35% solid content, Bayer company), polyacrylate / 10 parts of silicon-containing polyurethane composite emulsion, 2 parts of leveling agent 1120 (Momentive High-tech Materials Group), 1 part of defoamer foamstar 330 (Koning Chemical Company), 4.5 parts of thickener ASE-600, 0.5 parts of ammonia water, to 42 parts of ionized water.

[0086] The preparation method of the control sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com