Product containing rich low-viscosity resistant starch and preparing method of product

A resistant starch and low-viscosity technology, which is applied in the field of products rich in low-viscosity resistant starch and its preparation, can solve the problems of unfavorable industrial production, long production cycle, complicated process, etc., and achieve easy industrial production and low cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

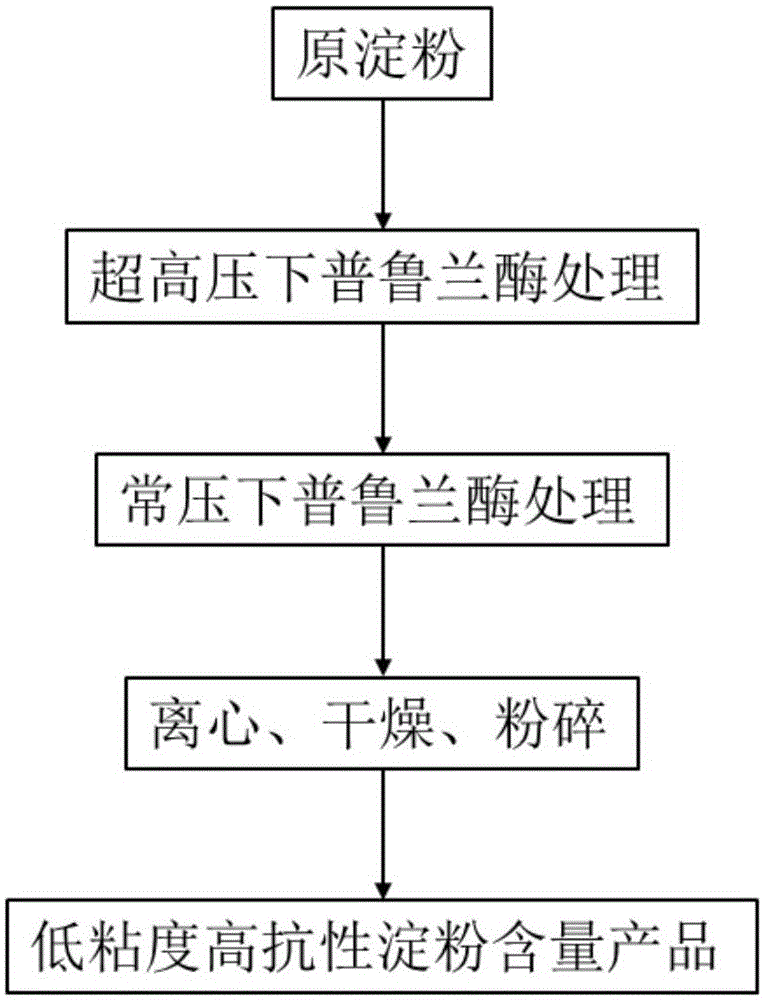

[0029] Embodiment 1 is rich in the preparation of the product of low-viscosity resistant starch

[0030] 1) Mix raw starch and pH5.5 buffer at a mass volume ratio (w / v, g / mL) of 1:10, add pullulanase at a concentration ratio of enzyme to substrate of 160U / g and pour into a vacuum In the packaging bag, seal; put the sample into the ultra-high pressure equipment, set the pressure of the ultra-high pressure equipment to 400MPa, and enzymatically hydrolyze at 60°C for 40min.

[0031] 2) Place the sample obtained in step 1) under normal pressure at 60°C for 10 hours of enzymatic hydrolysis with a stirring speed of 130rpm, then passivate the enzyme in an ice bath at 4°C for 10 minutes, centrifuge to remove the supernatant, dry and grind Flour and sieve to obtain a product with low viscosity and high resistant starch content.

Embodiment 2

[0032] Example 2: Preparation of products rich in low viscosity resistant starch

[0033] 1) Mix raw starch and pH5.5 buffer at a mass volume ratio (w / v, g / mL) of 1:10, add pullulanase at a concentration ratio of enzyme to substrate of 320 U / g and pour into a vacuum In the packaging bag, seal; put the sample into the ultra-high pressure equipment, set the pressure of the ultra-high pressure equipment to 200MPa, and enzymatically hydrolyze at 60°C for 40min.

[0034] 2) Place the sample obtained in step 1) under normal pressure at 60°C for 10 hours of enzymatic hydrolysis with a stirring speed of 130rpm, then passivate the enzyme in an ice bath at 4°C for 10 minutes, centrifuge to remove the supernatant, dry and grind Flour and sieve to obtain a product with low viscosity and high resistant starch content.

Embodiment 3

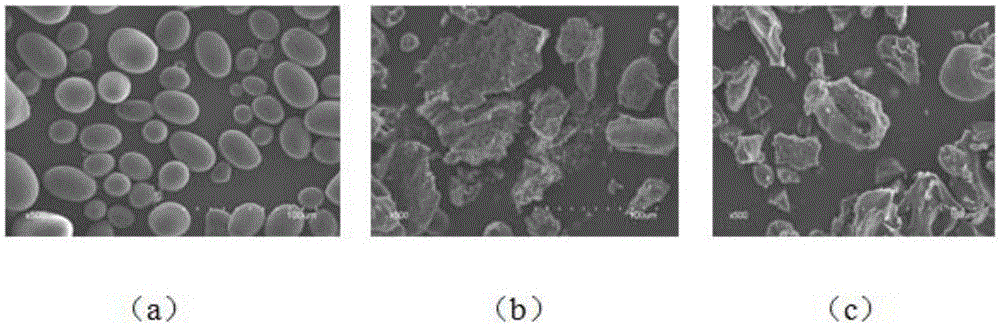

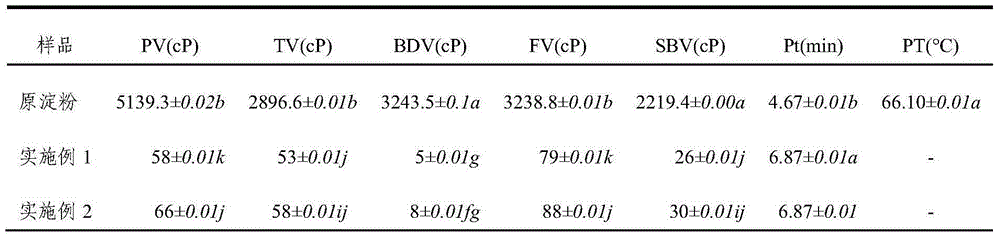

[0035] Example 3 Determination of gelatinization properties, resistant starch content and microstructure of products rich in low-viscosity resistant starch

[0036] 1) Determination of pasting properties

[0037]The gelatinization properties of the original potato starch and products with low viscosity and high resistant starch content (Example 1 and Example 2) were investigated using a rapid viscometer (RVA). Accurately weigh 3.0g of starch into the matching aluminum box, add 25ml of distilled water and mix well. The operation was performed using a fixed temperature ramp-down program with constant shear strain rate. The sample is kept at 50°C for 1min, heated to 95°C at a rate of 9.5°C / min, kept for 2.5min, then cooled to 50°C at a rate of 11.84°C / min, and kept at 50°C for 2min, the sample measurement time is 13min, and finally RVA viscosity curve of starch paste. The recording parameters include: peak viscosity (Peakviscosity, PV), valley viscosity (Troughviscosity, TV), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com