Titanium-based composite material, preparation method of railway vehicle brake disc and brake disc

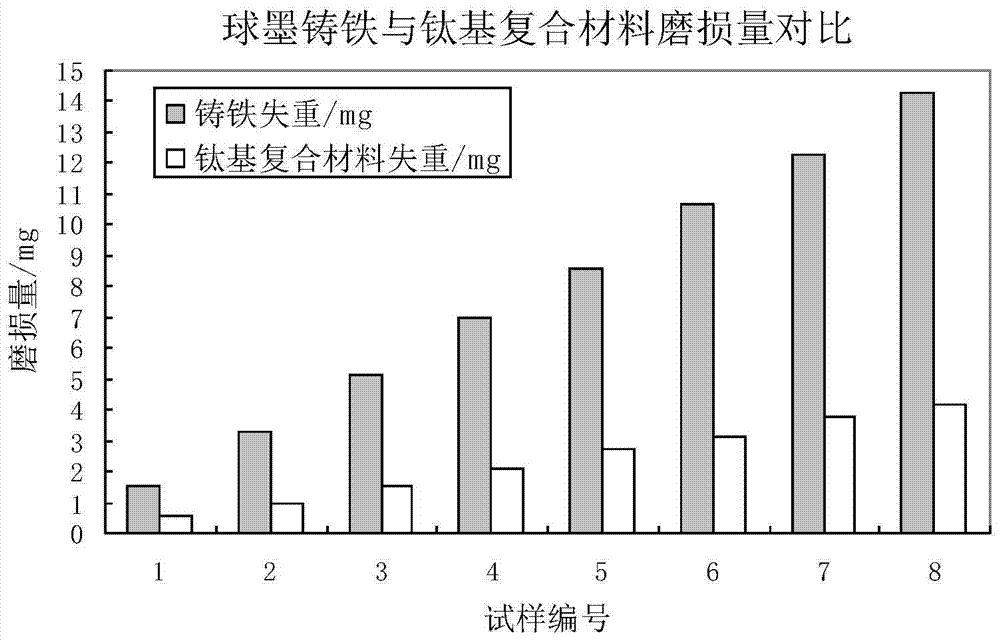

A titanium-based composite material and railway vehicle technology, applied in the field of rail transportation, can solve the problems of increased energy consumption and heavy weight of trains, and achieve good heat dissipation, high friction coefficient, and improved braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A titanium-based composite material, the titanium-based composite material is as follows in terms of mass percentage: the content of Al is 5%, the content of Si is 0.2%, the content of Sn is 1.5%, the content of Zr is 5.5%, the content of Mo is 0.5%, and the content of Nd is 0.1% %, the C content is 5%, and the balance is Ti.

Embodiment 2

[0033] A titanium-based composite material, the titanium-based composite material is as follows in terms of mass percentage: the content of Al is 5.3%, the content of Si is 0.4%, the content of Sn is 2.2%, the content of Zr is 6.5%, the content of Mo is 1.2%, and the content of Nd is 0.2% %, the C content is 6.5%, and the balance is Ti.

[0034] Example 2

[0035] The most preferred embodiment, a titanium-based composite material, the titanium-based composite material is as follows by mass percentage: the content of Al is 5%, the content of Si is 0.5%, the content of Sn is 2.5%, the content of Zr is 6.5%, and the range of Mo content is 1%. , Nd content is 0.15%, C content is 6%, and the balance is Ti.

[0036] A preparation method for a railway vehicle brake disc, comprising the steps of:

[0037] Step 1: Preparation of titanium-based composite ingot; the Al content is 5%, the Si content is 0.5%, the Sn content is 2.5%, the Zr content is 6.5%, the Mo content is 1.5%, the Nd ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com