Hybrid engine using compressed air and gasoline as power sources and method for using same

A technology of compressed air and hybrid power, applied in gaseous engine fuel, engine components, combustion engines, etc., can solve the problems of huge energy waste, achieve the effects of reducing energy loss, reducing changes, and good power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

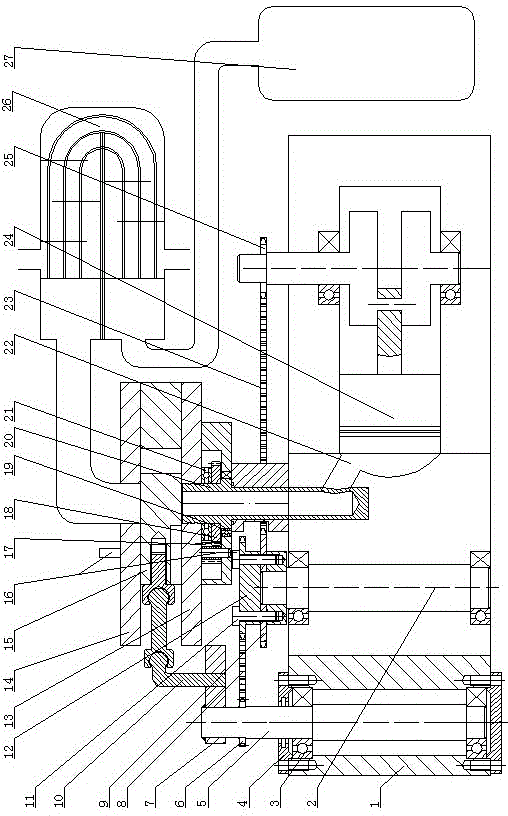

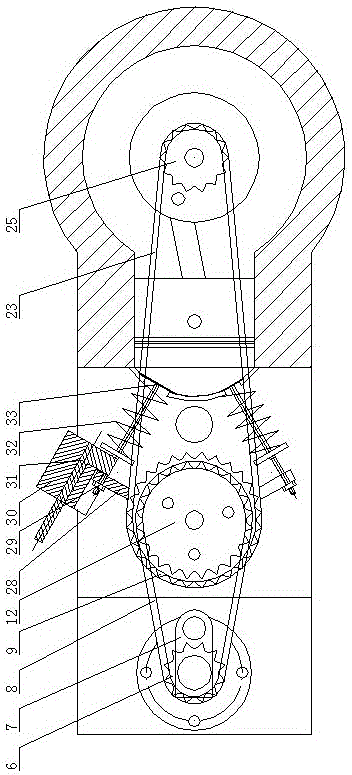

[0034] Such as Figure 1~3 As shown, a hybrid engine with compressed air and gasoline as the power source, including the original four-stroke naturally aspirated engine, gas storage tank, compressed air intake and exhaust mechanism, compressed air opening and closing mechanism, engine intake valve opening and closing Mechanism, fuel exhaust and compressed air heat exchange device.

[0035] The original four-stroke naturally aspirated engine includes piston 24, crankshaft small sprocket 25, crankshaft small sprocket 25 and gas distribution sprocket 9 linked by chain II 23, gas distribution sprocket 9 and large sprocket 12 are fixed by screws 11 On the camshaft 2, the camshaft 2 pushes away the spring 32 through the rocker arm 28 to open the intake valve 33, and the gap between the intake valve 33 and the rocker arm 28 is regulated by the valve adjustment screw 29.

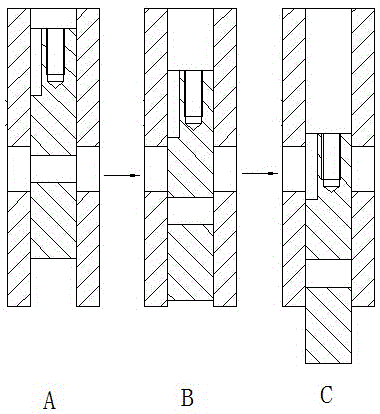

[0036] The compressed air intake and exhaust mechanism includes a bearing seat 1, a bearing 3, a bearing cover 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com