Method for preparing composite fiber-shaped capacitors continuously

A supercapacitor and composite fiber technology, which is applied in the field of flexible energy storage and wearable devices, can solve the problems of complex preparation methods, large internal resistance of fiber electrodes, and long preparation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

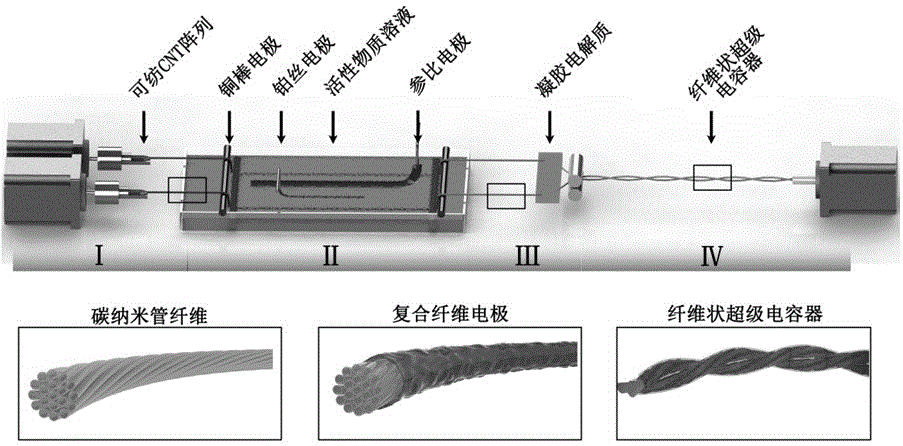

[0019] (1) Fix two spinnable carbon nanotube arrays on the rotating electrode, and continuously prepare carbon nanotube fibers from them by dry spinning, and the diameter of the obtained carbon nanotube fibers is 20 μm;

[0020] (2) Continuously pass the carbon nanotube fibers obtained in step (1) through an aqueous solution containing graphene oxide, wherein the concentration of graphene oxide is 3 mg / ml, and lithium perchlorate is 0.1M. A copper rod is used to connect the carbon nanotube fiber to an external circuit as a working electrode, a platinum wire is used as a counter electrode, and silver / silver chloride is used as a reference electrode. Set the voltage of electrochemical deposition to -1.2V, and the time of electrochemical deposition to 300s. Carbon nanotube / graphene composite fibers can be obtained by continuous electrochemical deposition;

[0021] (3) Continuously pass the carbon nanotube / graphene composite fiber obtained in step (2) through the phosphoric acid / ...

Embodiment 2

[0023] (1) Fix two spinnable carbon nanotube arrays on the rotating electrode, and continuously prepare carbon nanotube fibers from them by dry spinning, and the diameter of the obtained carbon nanotube fibers is 25 μm;

[0024] (2) Continuously pass the carbon nanotube fiber obtained in step (1) through an aqueous solution filled with manganese acetate, wherein the concentration of manganese acetate is 0.1M, and the concentration of sodium sulfate is 1.0M. A copper rod is used to connect the carbon nanotube fiber to an external circuit as a working electrode, a platinum wire is used as a counter electrode, and silver / silver chloride is used as a reference electrode. Set the voltage of electrochemical deposition to 0.7V, and the time of electrochemical deposition to 150s. Carbon nanotube / manganese dioxide composite fibers can be obtained by continuous electrochemical deposition;

[0025] (3) Pass the carbon nanotube / manganese dioxide composite fiber obtained in step (2) conti...

Embodiment 3

[0027] (1) Fix two spinnable carbon nanotube arrays on the rotating electrode, and continuously prepare carbon nanotube fibers from them by dry spinning, and the diameter of the obtained carbon nanotube fibers is 30 μm;

[0028] (2) Pass the carbon nanotube fibers obtained in step (1) continuously through an aqueous solution containing aniline, wherein the concentration of aniline is 0.1M, and the concentration of sulfuric acid is 1.0M. A copper rod is used to connect the carbon nanotube fiber to an external circuit as a working electrode, a platinum wire is used as a counter electrode, and silver / silver chloride is used as a reference electrode. Set the voltage of electrochemical deposition to 0.75V, and the time of electrochemical deposition to 100s. Carbon nanotube / polyaniline composite fibers can be obtained by continuous electrochemical deposition;

[0029] (3) Continuously pass the carbon nanotube / polyaniline composite fiber obtained in step (2) through the phosphoric a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com