Functional composite membrane for lithium-sulfur battery and preparation method of functional composite membrane

A lithium-sulfur battery and a composite separator technology are applied in the field of functional composite separators and their preparation to achieve the effects of high discharge specific capacity, improved cycle performance, and improved ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

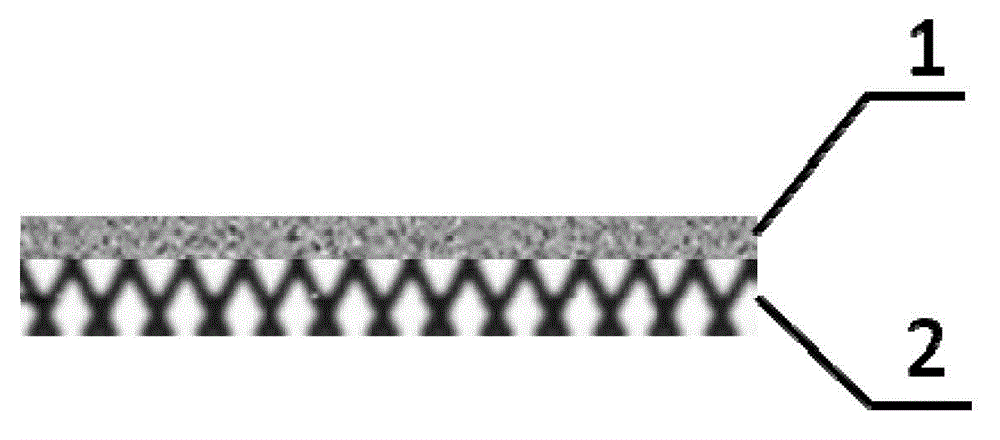

[0043] In one example, a method for preparing a composite membrane includes the following steps:

[0044] a) preparing the modification layer material into a uniform slurry;

[0045] b) coating the slurry on the surface of the diaphragm substrate and drying to obtain a composite diaphragm.

[0046] When the slurry contains electronically conductive materials and inorganic oxide materials, the electronically conductive materials and inorganic oxide materials can be proportioned according to their ratio in the composite diaphragm. Commonly used film-forming additives, such as adhesives and / or plasticizers, may also be included in the slurry. In one example, the electronically conductive material and / or inorganic oxide material and the binder are mixed at a mass ratio of 9:1 to 4:1, and dispersed in a solvent, and a uniformly dispersed slurry is obtained by ball milling or mechanical stirring material. The adhesive includes but not limited to one or more of polyvinyl alcohol, ...

Embodiment 1

[0051] 1. Mix 0.5g carbon nanotubes with 0.4gLi (1+x) Al x Ge (2-x) P 3 o 12 Ceramic powder and 0.1g polyethylene oxide are dispersed in anhydrous acetonitrile to prepare a uniform slurry, which is coated on a glass fiber diaphragm by a doctor blade coating method, and a composite diaphragm is obtained after drying;

[0052] 2. Disperse conductive agent acetylene black, sublimated sulfur and binder polyethylene oxide in acetonitrile and mix them uniformly by ball milling, and then dry the sulfur electrode after coating on aluminum foil;

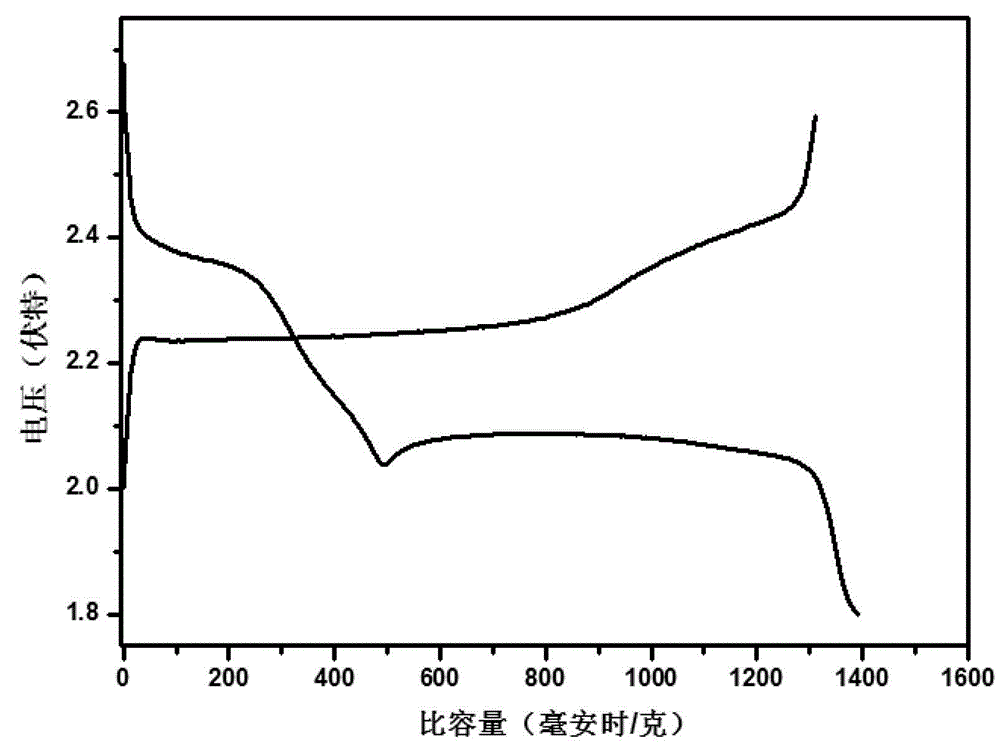

[0053] 3. The composite diaphragm is used as the diaphragm of the battery, the sulfur electrode is used as the positive electrode, and lithium metal is used as the counter electrode to assemble the CR2025 button battery. The electrolyte is added with 0.4 mol / L LiNO 3 0.6 mol / L of LiTFSIDME / DOL. At 0.5C rate, the first charge and discharge curve of the battery is as follows: figure 2 As shown, the first discharge capacity of the battery...

Embodiment 2

[0057] 1. Mix 0.5g acetylene black with 0.4gLi (1+x) Al x Ge (2-x) P 3 o 12 Ceramic powder and 0.1g PVDF are dispersed in NMP to prepare a uniform slurry, which is coated on one side of the polypropylene diaphragm by doctor blade coating method, and the composite diaphragm is obtained after drying;

[0058] 2. Disperse conductive agent acetylene black, sublimated sulfur and binder polyethylene oxide in acetonitrile and mix them uniformly by ball milling, and then dry the sulfur electrode after coating on aluminum foil;

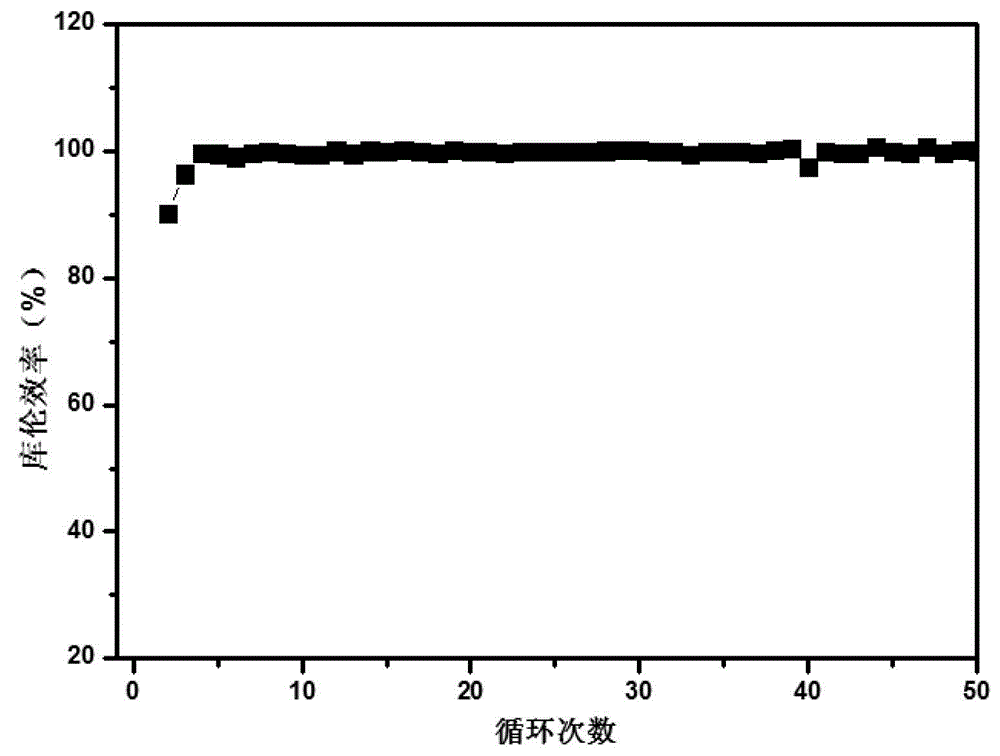

[0059] 3. The composite diaphragm is used as the diaphragm of the battery, the sulfur electrode is used as the positive electrode, and lithium metal is used as the counter electrode to assemble the CR2025 button battery. The electrolyte is added with 0.1 mol / L LiNO 3 1.0 mol / L LiTFSIDME / DOL. Such as Figure 6As shown, the test result of the lithium-sulfur battery using the composite diaphragm is a, and the test result of the lithium-sulfur battery using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com