Crispy food and production method thereof

A production method and food technology, which can be used in food preparation, food drying, food freezing and other directions, can solve the problems of limited improvement in the crispness of taste and small reduction in fat content, and achieve fine and uniform product taste, uniform distribution, and ice crystal distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

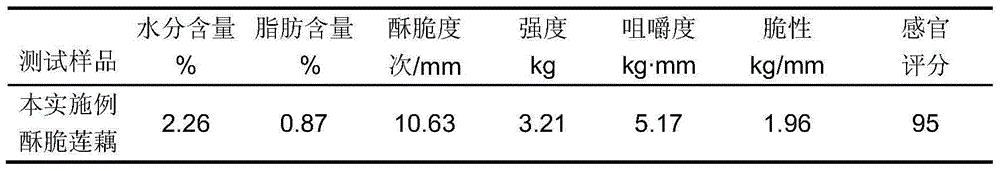

Embodiment 1

[0036] First, weigh main ingredients: 100 parts of lotus root; auxiliary materials: 0.5 parts of salt, 0.5 parts of white sugar, 0.1 parts of citrate, 0.1 parts of maltodextrin, and 0.1 parts of maltose. In embodiment 1~3, described 1 part is 1kg, carries out following operation respectively successively:

[0037] Pre-treatment: cleaning and peeling the lotus root, cutting it into thin slices with a thickness of less than 1 mm, washing with water to obtain clean lotus root;

[0038] High-pressure conditioning: mix the clean lotus root obtained from the pre-treatment with water at a weight ratio of 1:1, place it at 30°C and 0.11MPa for 2 minutes, and obtain high-pressure conditioning lotus root;

[0039] Low-pressure dipping: mix 100 parts of drinking water with the auxiliary materials to obtain a steeping liquid, mix the high-pressure conditioned lotus root with the steeping liquid at a weight ratio of 1:1, and treat at 20°C and 0.05 MPa for 2 minutes to obtain a low-pressure ...

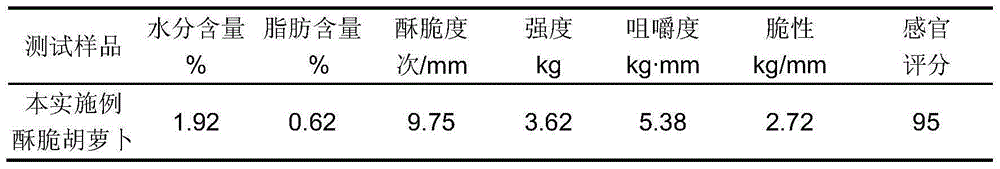

Embodiment 2

[0055] First, weigh the main ingredients: 100 parts of carrots; auxiliary materials: 2 parts of table salt, 2 parts of white sugar, 2 parts of citrate, 2 parts of maltodextrin, and 1 part of maltose, and perform the following operations in turn:

[0056] Pre-treatment: cleaning and peeling the carrots, cutting them into thin slices with a thickness of less than 1 mm, washing with water to obtain clean carrots;

[0057]High-pressure conditioning: mix the clean carrots obtained from the pretreatment with water at a weight ratio of 1:2, place them at 50°C and 0.5MPa for 5 minutes, and obtain high-pressure conditioning carrots;

[0058] Low-pressure dipping: mix 100 parts of drinking water with the auxiliary materials to obtain a dipping solution, mix the high-pressure conditioned carrots with the dipping solution at a weight ratio of 1:5, and treat them at 30°C and 0.09MPa for 10 minutes to obtain low-pressure dipped carrots;

[0059] Freezing: Freeze low-pressure soaked carrots ...

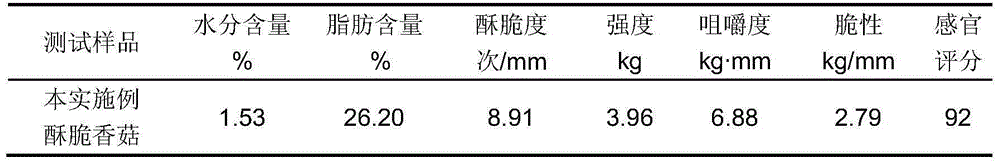

Embodiment 3

[0066] First, weigh main ingredients: 100 parts of shiitake mushrooms; auxiliary materials: 0.5 parts of salt, 0.5 parts of white sugar, 0.1 parts of citrate, 0.1 parts of maltodextrin, and 0.1 parts of maltose. In embodiment 1~3, described 1 part is 1kg, carries out following operation respectively successively:

[0067] Pre-treatment: clean the shiitake mushrooms and wash them with water to obtain clean shiitake mushrooms;

[0068] High-pressure conditioning: Mix the clean shiitake mushrooms obtained from the pretreatment with water at a weight ratio of 1:1, place them at 30°C and 0.11MPa for 2 minutes, and obtain high-pressure conditioning shiitake mushrooms;

[0069] Low-pressure soaking: mix 100 parts of drinking water with the auxiliary materials to obtain a soaking liquid, mix the high-pressure conditioned shiitake mushrooms with the soaking liquid at a weight ratio of 1:1, and treat them at 20°C and 0.05MPa for 2 minutes to obtain low-pressure soaked shiitake mushrooms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com