Hangjin 2# soil loaded nano-zero valent iron adsorption material, preparation method and application

A nano-zero valent iron, adsorption material technology, applied in the fields of adsorption water/sewage treatment, chemical instruments and methods, cation exchange, etc. The possibility of engineering applications, etc., to achieve the effect of not easy particle agglomeration and self-oxidation, good ion exchange capacity and adsorption capacity, and improving resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

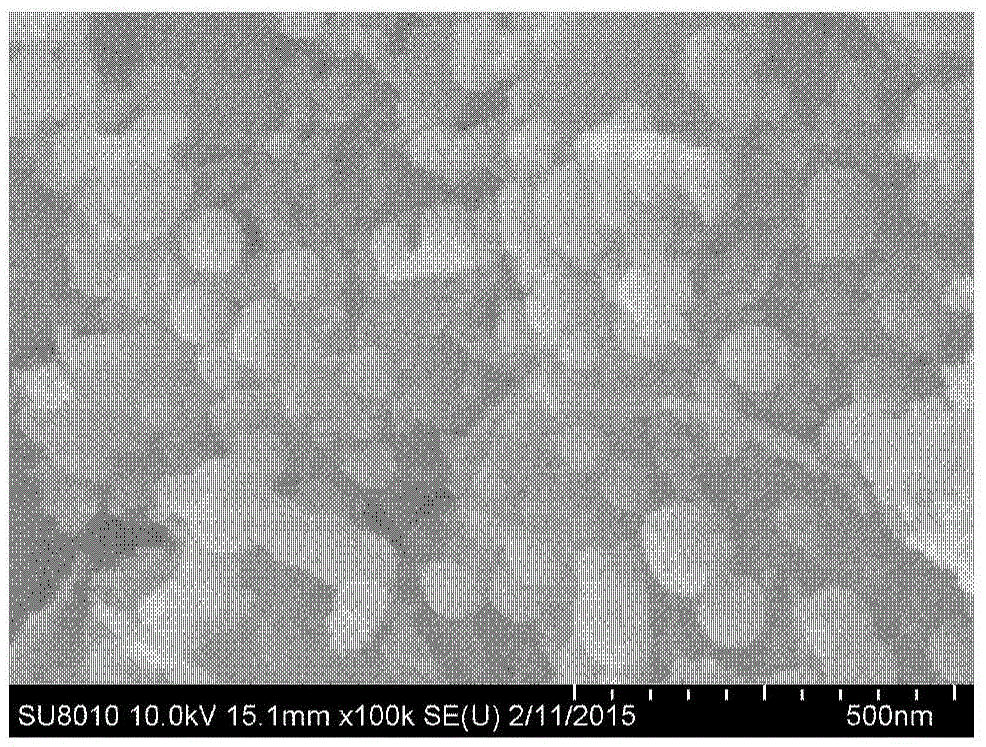

Image

Examples

preparation example Construction

[0037] The preparation method of Hangjin 2# soil-loaded nanometer zero-valent iron is: under the condition of nitrogen atmosphere, with the help of external reducing agent sodium borohydride (NaBH 4 ) reduction, making iron-containing oxides (FeCl 3 ·6H 2O) reduced to nanometer zero-valent iron, and evenly dispersed on the surface of the carrier material Hangjin 2# soil. Including the following steps:

[0038] 1) 1.932g of FeCl 3 ·6H 2 O was dissolved in 50ml ethanol solution (40ml ethanol, 10ml water) to obtain a mixed solution.

[0039] 2) Put the mixed solution in step 1 into a three-necked flask, and add 2.00 g of Hangjin soil that has been simply ground and passed through a 200-mesh sieve. Make the mass ratio of nanometer zero valent iron (NZVI) to Hangjin 2# soil be 1:4-5.

[0040] 3) Pass nitrogen gas into the product of step 2 and magnetically stir for 30 minutes to remove oxygen in the mixture.

[0041] 4) Dissolve 0.708g of reducing agent (such as sodium boroh...

Embodiment 1

[0045] Example 1: Preparation of Hangjin Soil 2# loaded nanometer zero-valent iron

[0046] The contents of the main chemical components of the Hangjin 2# soil used in this example are shown in Table 1.

[0047] 1) 1.932g of FeCl 3 ·6H 2 O was dissolved in 50ml ethanol solution (40ml ethanol, 10ml water) to obtain a mixed solution.

[0048] 2) Put the mixed solution in step 1 into a three-necked flask, and add 2.00 g of Hangjin soil that has been simply ground and passed through a 200-mesh sieve. The mass ratio of nanometer zero valent iron (NZVI) to Hangjin 2# soil is 1:5.

[0049] 3) The product of step 2 was passed through nitrogen and magnetically stirred for 30 minutes to remove the oxygen in the mixture.

[0050] 4) Dissolve 0.708g of sodium borohydride in 100ml of water, and transfer the sodium borohydride solution to a 250ml pear-shaped flask.

[0051] 5) Add the sodium borohydride solution of step 4 to the product of step 3 at a rate of 2-3 drops / second under the...

Embodiment 2

[0054] Example 2: Hangjin clay-loaded nano-zero-valent iron material is applied to the decolorization of methyl orange

[0055] Take 100ml of the newly configured 50mg / L methyl orange standard solution in a 250ml beaker, add the synthesized composite material NZVIHJ into the methyl orange solution, the initial concentration of methyl orange is 50mg / L, and the dosage of the composite material is 5g / L L, NZVI Hangjin 2# soil load ratio is 1:5. Stir continuously, the speed is 250 rpm, take 1ml of samples at 30s, 1min, 2min, 3min, 4min, 5min, 6min, 9min, 12min, 15min, 20min, 25min, 30min, and 40min, add 1ml to a 25ml colorimetric tube, and constant volume , using a UV spectrophotometer to measure its absorbance, compared with the absorbance of the stock solution, to study the effect of the synthesized Hangjin soil loaded with nanometer zero-valent iron on the removal of methyl orange. The experimental results show that the synthesized Hangjin soil loaded with nano-zero-valent iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com