Modified carbon nanotube treatment method

A processing method and technology of carbon nanotubes, applied in the field of material science, can solve the problems of composite material processing and use performance decline, unsatisfactory dispersibility, unfriendly environment, etc., to improve biocompatibility, improve processing and use performance. , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

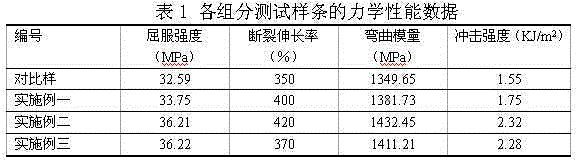

[0013] Embodiment 1 of the present invention: the processing method of modified carbon nanotubes, comprises the following steps,

[0014] 1) React carbon nanotubes in a mixed solution of 150ml sulfuric acid and nitric acid, the mass ratio of sulfuric acid and nitric acid is 1:3, and react at 80°C for 6 hours to obtain purified carbon nanotubes CNT-OH with hydroxyl groups on the surface;

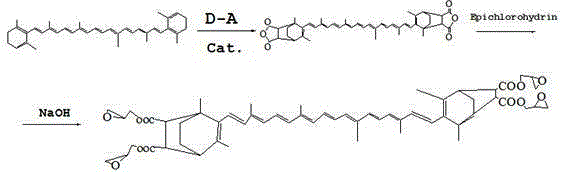

[0015] 2) Add 25g of γ-carotene and 9.8g of maleic anhydride to 60ml of benzene, mix well, and undergo a D-A reaction at 140°C for 4 hours under the protection of nitrogen; then add 93g of epichlorohydrin to the reacted mixture And 0.7g of ammonium bromide, heated to reflux for 6h, then cooled to 73°C, added excess sodium hydroxide, and washed to obtain long-chain compounds;

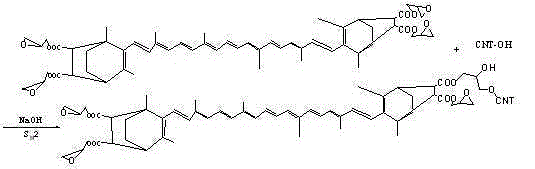

[0016] 3) Add 0.3mol of long-chain compound to 30ml of aqueous solution, add 0.1mol of sodium hydroxide at 120°C, react for 3h under nitrogen, then add 0.3mol of CNT-OH and 0.2g of tetrabutylammonium bromide to reflux ...

Embodiment 2

[0017] Embodiment 2 of the present invention: the processing method of modified carbon nanotubes, comprises the following steps,

[0018] 1) React carbon nanotubes in a mixed solution of 120ml sulfuric acid and nitric acid, the volume ratio of sulfuric acid and nitric acid is 1:3, and react at 75°C for 7 hours to obtain purified carbon nanotubes CNT-OH containing hydroxyl groups on the surface;

[0019] 2) Add 22g of γ-carotene and 9g of maleic anhydride into 60ml of toluene, mix well, and undergo a D-A reaction at 170°C for 4 hours under the protection of nitrogen; then add 90g of epichlorohydrin and 0.6g ammonium bromide, heated to reflux for 5h, then cooled to 75°C, added excess sodium hydroxide, and washed to obtain long-chain compounds;

[0020] 3) Add 0.5mol of long-chain compound to 30ml of aqueous solution, add 0.15mol of sodium hydroxide at 130°C, react for 4 hours under nitrogen, then add 0.5mol of CNT-OH and 0.5g of tetrabutylammonium bromide to reflux After coolin...

Embodiment 3

[0021] Embodiment 3 of the present invention: the processing method of modified carbon nanotubes, comprises the following steps,

[0022] 1) React carbon nanotubes in a mixed solution of 150ml sulfuric acid and nitric acid, the volume ratio of sulfuric acid and nitric acid is 1:3, and react at 85°C for 5 hours to obtain purified carbon nanotubes CNT-OH containing hydroxyl groups on the surface;

[0023] 2) Add 27g of γ-carotene and 11g of maleic anhydride into 60ml of acetonitrile, mix well, and undergo a D-A reaction at 130°C for 5 hours under nitrogen protection; then add 90g of epichlorohydrin and 0.6g ammonium bromide, heated to reflux for 4 hours, then cooled to 75°C, added excess sodium hydroxide, and washed to obtain long-chain compounds;

[0024] 3) Add 1mol of long-chain compound to 60ml of aqueous solution, add 0.3mol of sodium hydroxide at 140°C, react for 5h under nitrogen, then add 1mol of CNT-OH and 1g of tetrabutylammonium bromide to reflux for 5h, then After c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com