Phosphorus-nitrogen-silicon compound loaded montmorillonite flame retardant and preparation method thereof

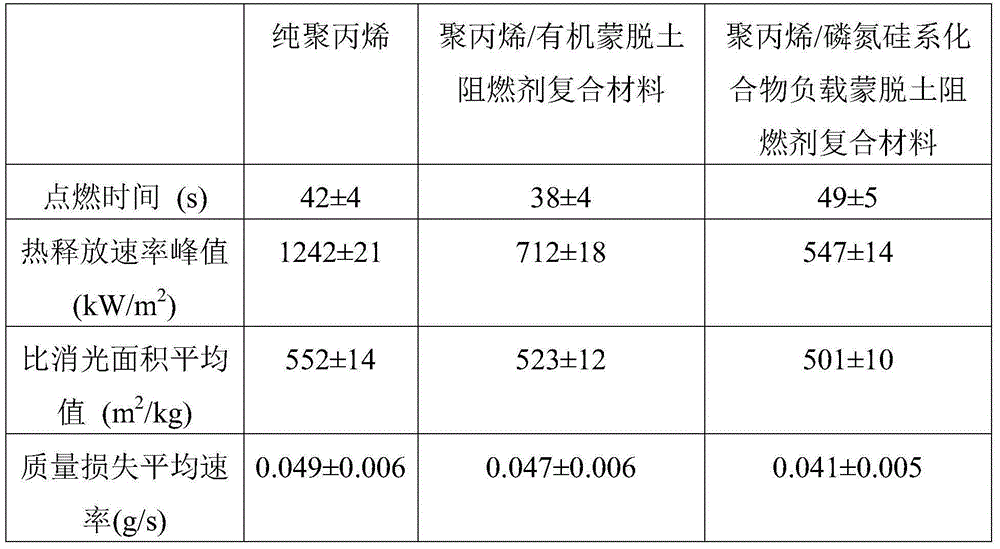

A technology containing a phosphorus oxychloride compound and montmorillonite is applied in the field of flame retardants, which can solve the problems of unfavorable industrial production, poor dispersion and high cost, and achieve the effects of simplifying the synthesis process route, simple process route and reducing the preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 1,500 kg of montmorillonite to a ball mill connected with a nitrogen inlet pipe. The size of the ball mill is Ф900×1800, and the ball loading capacity is 1.5 tons. Under the condition of the drum speed of the ball mill at 38 rpm, add 150 kg of 3-ammonia Propyl trimethoxy silane and 175 kilograms of diphenoxy phosphorus oxychlorides were ground and reacted for 40 minutes under the condition of 0.5 cubic meters per minute of nitrogen flow rate to prepare phosphorus nitrogen silicon series compound loaded montmorillonite flame retardant, The yield was 97.9%.

Embodiment 2

[0024] The synthesis operation of the montmorillonite flame retardant supported by phosphorus nitrogen silicon compounds is the same as in Example 1, and the raw materials are: montmorillonite, N-aminoethyl-γ-aminopropyltrimethoxysilane, and dimethylphosphoryl chloride. The amount of montmorillonite added is 38,000 kg, and the mass ratio of montmorillonite to N-aminoethyl-γ-aminopropyltrimethoxysilane is 1.0:0.02, and N-aminoethyl-γ-aminopropyltrimethoxysilane The ratio of the feed material of oxysilane to dimethylphosphoryl chloride is 1.0:2.5, the size of the ball mill is Ф2200×7500, the ball loading capacity is 35 tons, the drum speed is 21.7 rpm, the grinding time is 20 minutes, and nitrogen is introduced The flow rate was 0.1 m3 / min and the yield was 99.1%.

Embodiment 3

[0026] The synthesis operation of phosphorus nitrogen silicon compound loaded montmorillonite flame retardant is the same as in Example 1, the raw materials are: montmorillonite, 3-(2-aminoethylamino)propyltriethoxysilane, diethylphosphoryl chloride . The addition of montmorillonite is 4500 kg, and the mass ratio of montmorillonite to 3-(2-aminoethylamino)propyltriethoxysilane is 1.0:0.38, 3-(2-aminoethylamino) The ratio of propyltriethoxysilane to diethylphosphoryl chloride is 1.0:2.2, the size of the ball mill is Ф1500×3000, the ball loading capacity is 7.5 tons, the drum speed is 29.7 rpm, and the grinding time is 150 minutes , the nitrogen flow rate was 20 cubic meters per minute, and the yield was 97.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com