Preparation method of hyper branched copolymerized polyimide/zinc oxide (ZnO) hybrid insulated film

A technology of copolymerized polyimide and copolymerized polyamic acid film, which is applied in the field of polymer material preparation, can solve the problems that are difficult to meet, the blends are prone to agglomeration, and the composite materials cannot effectively improve the dielectric properties, so as to reduce the Effects of agglomeration, improvement of dielectric properties and insulation, improvement of thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0026] The invention provides a method for preparing a hyperbranched copolymerized polyimide / zinc oxide hybrid insulating film, comprising the following steps:

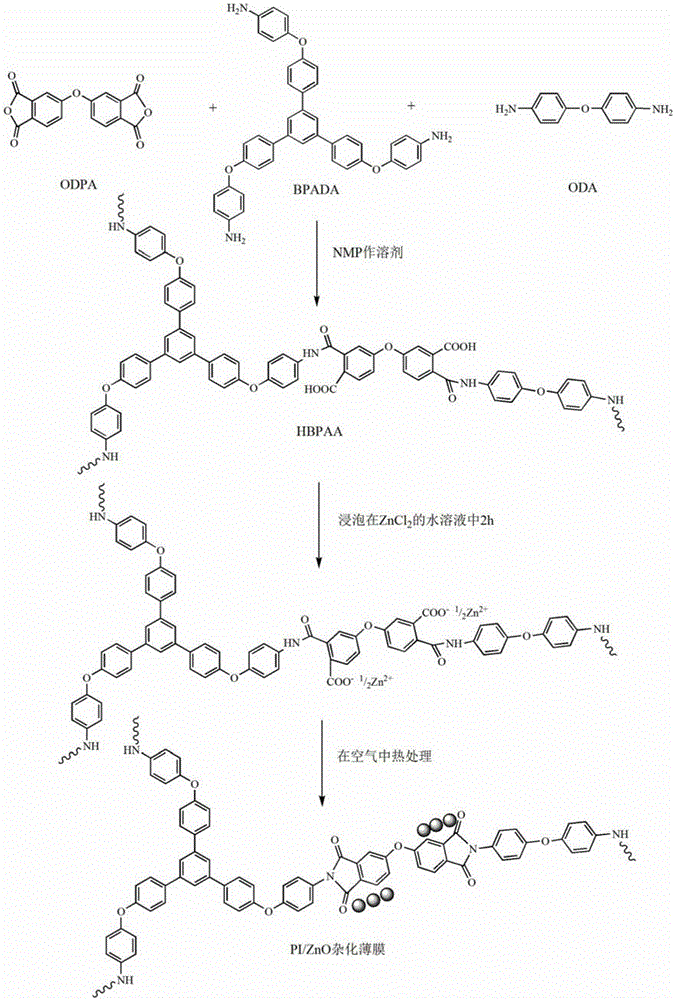

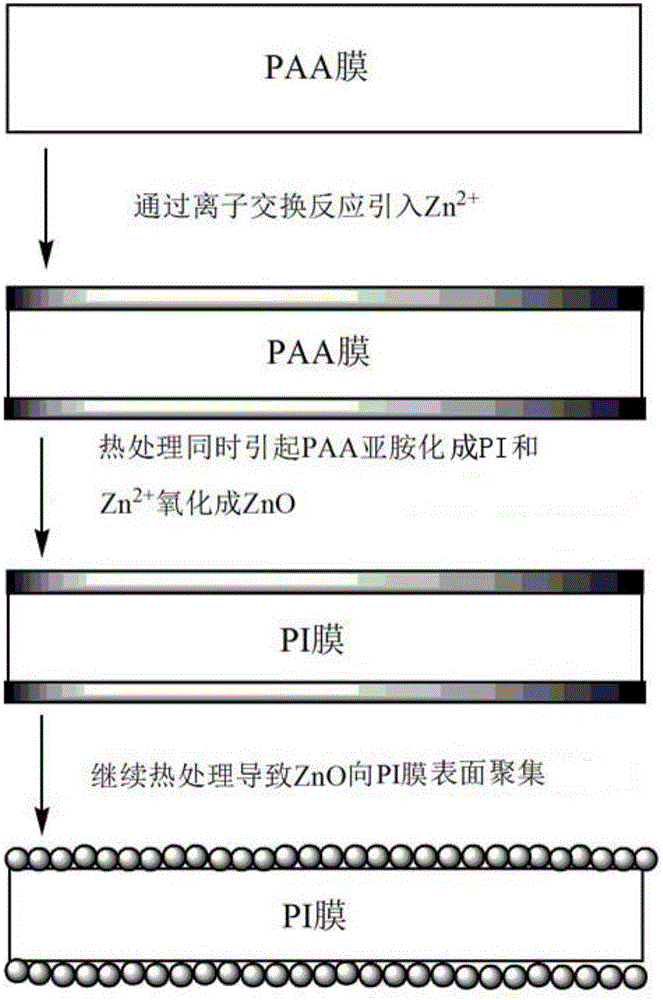

[0027] 1) Preparation of hyperbranched copolymerized polyamic acid film (co-HBPAA): three monomers of ODPA, TAPOPB and ODA were used as raw materials, and the polycondensation reaction was carried out at a molar ratio of 1:0.4:0.5 (such as figure 1 Shown): Dissolve ODPA with 10ml NMP, after completely dissolving, in N 2 In the ice-water bath under the atmosphere, use a dropping funnel to slowly add dropwise to the two-necked flask containing the NMP solution of 10mlTAPOPB and ODA within 1h. , drop the obtained solution on a glass plate with a silica gel frame, put it in a vacuum oven at 60°C for 12 hours to remove the residual solvent, and obtain a hyperbranched copolymerize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com