Preparation method of graphite-phase carbon nitride solid fluorescent powder and application thereof in light fingerprint extraction

A graphite-phase carbon nitride and fluorescent powder technology, applied in chemical instruments and methods, nitrogen and non-metallic compounds, luminescent materials, etc., can solve the problems of weak fluorescence intensity and low quantum yield, and achieve easy synthesis and synthetic methods Simple, easy to compare and save the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

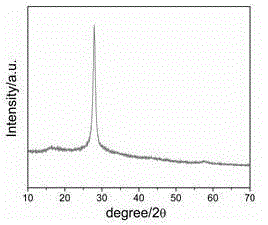

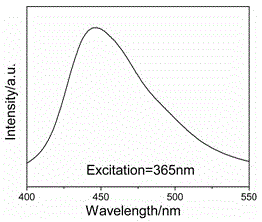

[0023] A preparation method of graphite phase carbon nitride solid fluorescent powder, comprising the steps of:

[0024] a, take 8g of melamine, 10g of sodium chloride and 12g of potassium chloride in a mortar, fully grind and mix evenly for subsequent use;

[0025] b. Transfer the mixture prepared in step a into a crucible, place it in a muffle furnace, and calcine at a high temperature for 1 hour in an air atmosphere, and the calcination temperature is 670° C.;

[0026] c. Then cool to room temperature, crush the calcined block product and disperse it in 0.3mol / l dilute hydrochloric acid, then centrifuge to remove the supernatant; then wash repeatedly, and place the washed product in an oven at 60°C Drying in medium is graphite phase carbon nitride solid phosphor.

Embodiment 2

[0032] A preparation method of graphite phase carbon nitride solid fluorescent powder, comprising the steps of:

[0033] a. Weigh 9g of melamine, 11g of sodium chloride and 13g of potassium chloride in a mortar, grind and mix well for later use.

[0034] b. Transfer the mixed material prepared in step a into a crucible, place it in a muffle furnace, and calcine at a high temperature for 1 hour in an air atmosphere at a calcination temperature of 670°C.

[0035] c. Then cool to room temperature, crush the calcined block product and disperse it in 0.3mol / l dilute hydrochloric acid, then centrifuge to remove the supernatant; then wash repeatedly, and place the washed product in an oven at 60°C Drying in medium is graphite phase carbon nitride solid phosphor.

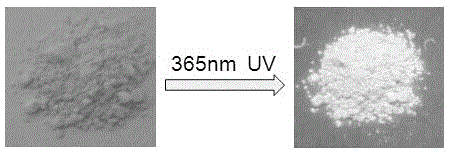

[0036] Application examples of graphitic carbon nitride solid phosphors for the display of fingerprints on the surface of different objects:

[0037] Select the mouse, cigarette case, can, and glass as the fingerprint car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com