Nitride light emitting diode (LED) based on stress controlled electroplating and substrate transferring and fabrication method thereof

A technology of stress control and substrate transfer, applied in circuits, electrical components, semiconductor devices, etc., can solve problems such as high temperature, epitaxial layer cracking, and increased epitaxial layer damage, and achieve the goals of preventing leakage, ensuring compactness, and ensuring integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

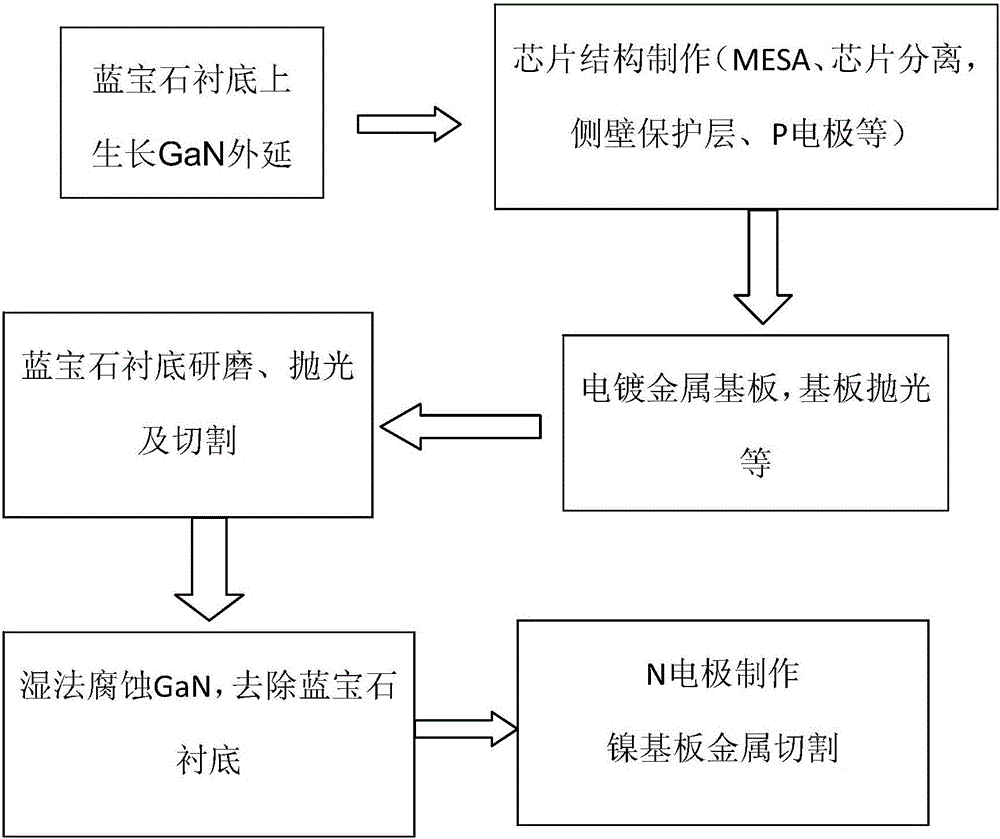

[0057] Such as figure 1 As shown in Fig. 2, the method for preparing a vertical structure LED by peeling off the sapphire sapphire substrate of the present invention by wet etching, the specific preparation process is as follows:

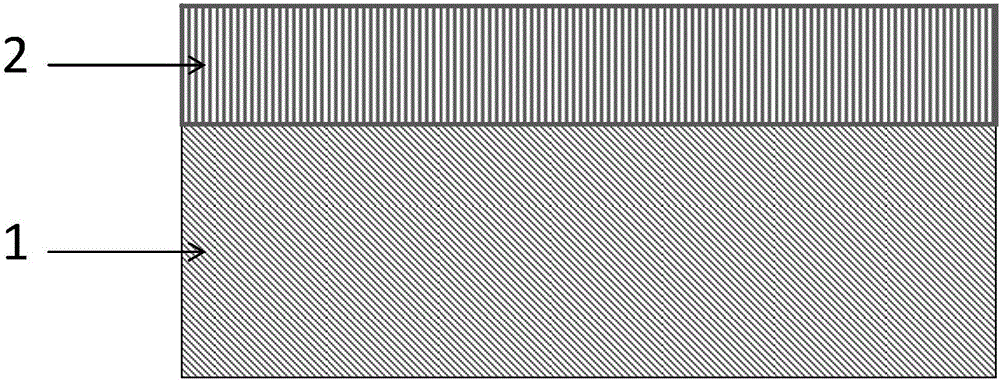

[0058] [1] Using an MOCVD epitaxial growth system, a GaN epitaxial layer 2 is grown on a c-plane patterned sapphire substrate 1, and the epitaxial layers are grown sequentially in the order of GaN buffer layer, u-GaN layer, n-GaN layer, and multi-quantum well layer (MQW) and p-GaN layer, the thickness of the entire GaN-based epitaxial layer should be greater than 6 μm. Such as Figure 2a shown.

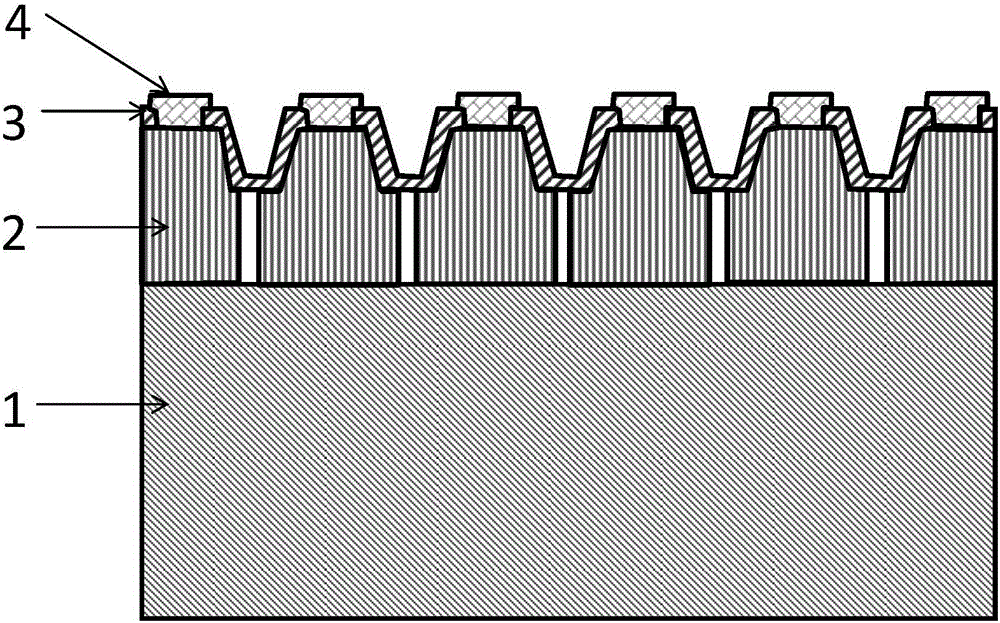

[0059] [2] Through photolithography and inductively coupled plasma dry etching process, the gallium nitride epitaxial layer (ie GaN epitaxial layer 2) on the sapphire substrate is etched to a depth of 3.2 μm, and its thickness is controlled by adjusting the photolithography conditions. The inclination angle of the side wall is 40-70 degrees.

[0060] [3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com