Weather-resisting chemico-mechanical polishing pad

A chemical-mechanical, weather-resistant technology, applied in grinding/polishing equipment, wheels with flexible working parts, abrasives, etc., can solve problems such as unfavorable material storage and use, material aging and damage, affecting appearance, etc., Achieve the effect of extending storage and service life, preventing aging and damage, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

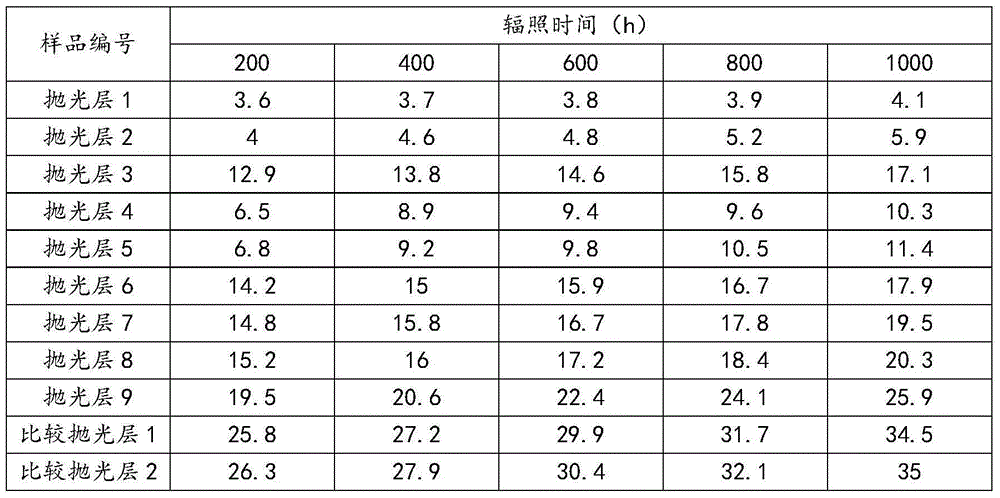

Examples

Embodiment 1

[0026] Under the condition of 40°C oil bath, put 100g of 1,6-hexamethylene diisocyanate into a three-necked flask, and the stirring speed is 300 rpm; Hours later, the reactants were subjected to vacuum defoaming treatment to obtain weather-resistant polyurethane prepolymer A1 with a viscosity of 22000 mPa·S.

[0027] Weigh 5g of functional filler and add it to A1 above, and mix evenly; then add 53.4g of curing agent and mix evenly at high speed, pour the mixture into a mold, and then put the product in an oven at 90°C for 16 hours to obtain a polyurethane polishing pad Polishing layer (polishing layer 1 for short).

Embodiment 2

[0029]Under the condition of 40°C oil bath, put 100g of isophorone diisocyanate into a three-necked flask, and the stirring speed is 300 rpm; then add 400g of polyether polyol dropwise into isophorone diisocyanate and react for 2 hours Afterwards, the reactants were subjected to vacuum defoaming treatment to obtain weather-resistant polyurethane prepolymer A2 with a viscosity of 35000mPa·S.

[0030] Weigh 4g of functional filler and add it to A2 above, and mix evenly; then add 13.4g of curing agent and mix evenly at high speed, pour the mixture into a mold, and then put the product in an oven at 90°C for 16 hours to obtain a polyurethane polishing pad Polishing layer (abbreviated as polishing layer 2).

Embodiment 3

[0032] Under the condition of 40°C oil bath, put 100g of xylylene diisocyanate into a three-necked flask, and the stirring speed is 300 rpm; then add 400g of polyether polyol dropwise into xylylene diisocyanate, and After 2 hours, the reactants were subjected to vacuum defoaming treatment to obtain weather-resistant polyurethane prepolymer A3 with a viscosity of 28000 mPa·S.

[0033] Weigh 4.5g of functional filler and add it to A3 above, and mix evenly; then add 35g of curing agent and mix evenly at high speed, pour the mixture into a mold, and then put the product in an oven at 90°C for 16 hours to obtain a polyurethane polishing pad Polishing layer (polishing layer 3 for short).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com