Desulfurization wastewater pre-evaporation zero discharge treatment apparatus

A technology for desulfurization wastewater and treatment equipment, which is applied in water/sewage treatment, water/sludge/sewage treatment, and the use of liquid separation agents, etc., which can solve problems such as high operating costs, high equipment costs, and strict environmental protection requirements, and achieve extended Effect of residence time, reduction of operation risk and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

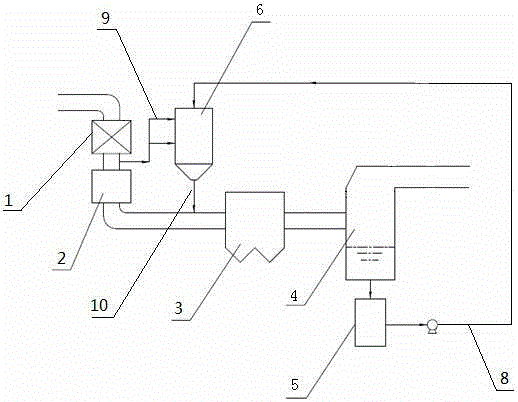

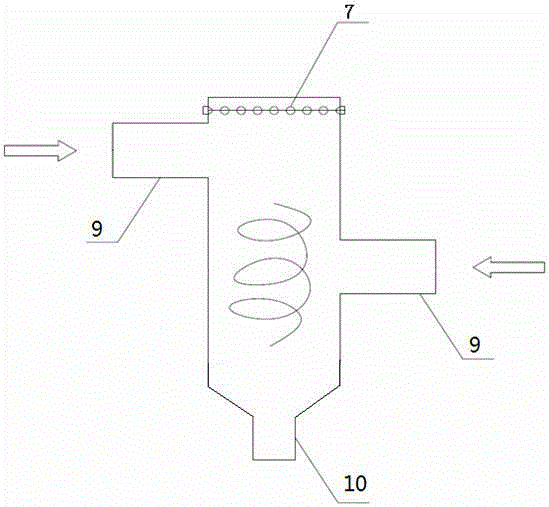

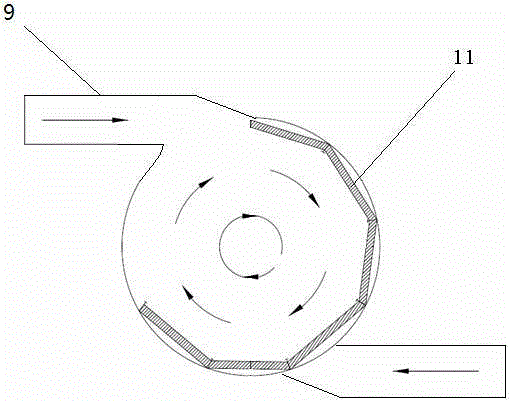

[0019] As shown in the figure, a pre-evaporation and zero-emission treatment device for desulfurization wastewater includes a denitrification device 1, an air preheater 2, a dust collector 3 and a desulfurization tower 4 connected in sequence by pipelines; the denitrification device 1 is connected to the mechanical equipment. On the waste heat flue gas discharge pipe, the desulfurization tower 4 has a spray layer for purifying the flue gas. The spray layer sprays desulfurization slurry, and the desulfurization slurry sprays and contacts the flue gas entering the desulfurization tower 4. The upper part of the layer also has a purified gas discharge pipeline, which is located in the desulfurization tower 4 and is connected to the waste water tank 5. The gypsum slurry discharged from the desulfurization tower 4 passes through the dehy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com