Bio-organic fertilizer produced by using edible fungus residues as main material and preparation method thereof

A bio-organic fertilizer and fungus residue technology, which is applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve the problems of single nutrition of organic fertilizer, low utilization rate of edible fungus residue, etc. Healthy growth, the effect of promoting plant growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

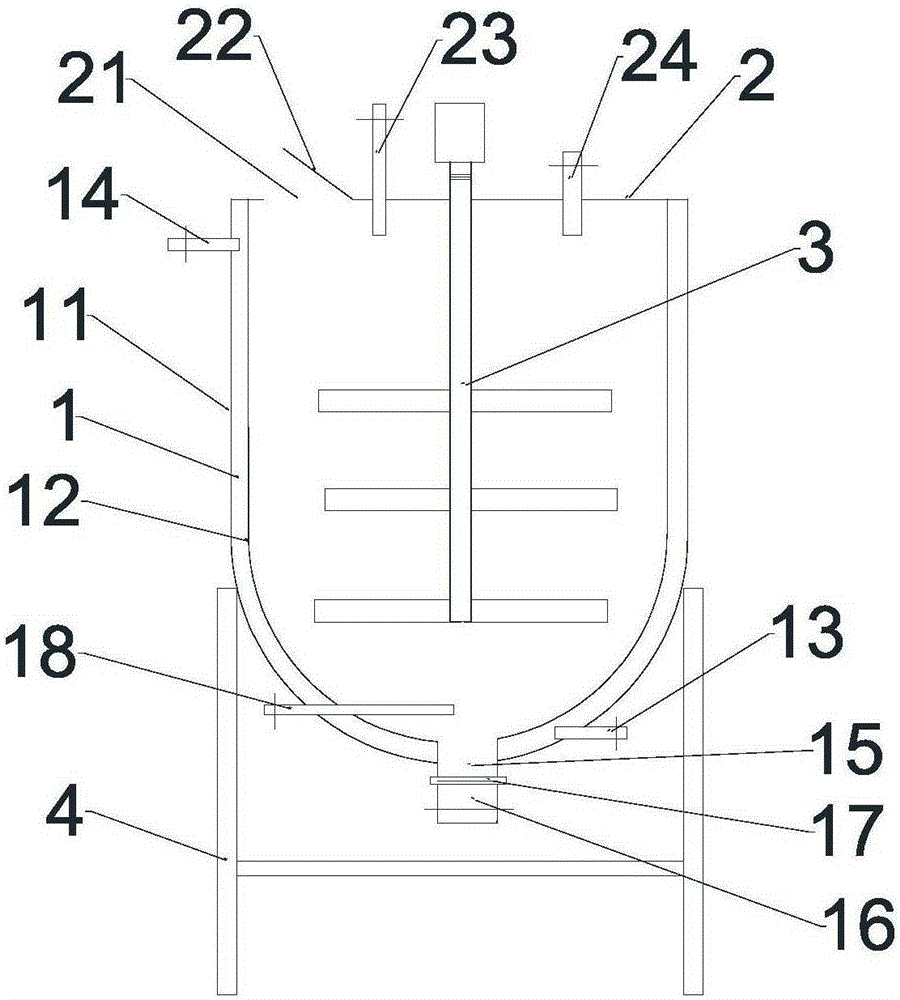

Image

Examples

Embodiment 1

[0040] A bio-organic fertilizer produced with edible fungus dregs as the main ingredient, mainly made of the following raw materials in parts by weight: 195 parts of edible fungus dregs, 195 parts of water, 33 parts of durian shells, 25 parts of Chinese herbal medicines, and 23 parts of lobster shells , 20 parts of poultry manure, 18 parts of acacia leaves, 14 parts of gray vegetables, 8 parts of fish scale powder, 1.2 parts of Trichoderma and 0.8 parts of enzyme bacteria, of which,

[0041] The Trichoderma consists of the following raw materials in parts by weight: 10 parts of Trichoderma viride, 10 parts of Trichoderma longibrachiata and 10 parts of Trichoderma harsetii; the Chinese herbal medicine consists of the following raw materials in parts by weight: Duckweed Grass 22 parts, 20 parts of camphor leaves, 20 parts of astragalus, 12 parts of calamus and 5 parts of mint.

[0042]In the bio-organic fertilizer produced with edible fungus residue as the main ingredient, the e...

Embodiment 2

[0060] A bio-organic fertilizer produced with edible fungus dregs as the main ingredient, mainly made of the following raw materials in parts by weight: 198 parts of edible fungus dregs, 198 parts of water, 34 parts of durian shells, 28 parts of Chinese herbal medicines, and 24 parts of lobster shells , 21 parts of poultry feces, 19 parts of acacia leaves, 15 parts of gray vegetables, 9 parts of fish scale powder, 1.3 parts of Trichoderma and 0.9 parts of enzyme bacteria, of which,

[0061] The Trichoderma consists of the following raw materials in parts by weight: 10 parts of Trichoderma viride, 10 parts of Trichoderma longibrachiata and 10 parts of Trichoderma harsetii; the Chinese herbal medicine consists of the following raw materials in parts by weight: Duckweed Grass 23 parts, 21 parts of camphor leaves, 21 parts of astragalus, 13 parts of calamus and 7 parts of mint.

[0062] In the bio-organic fertilizer produced with edible fungus residue as the main ingredient, the e...

Embodiment 3

[0080] A bio-organic fertilizer produced with edible fungus dregs as the main ingredient, mainly made of the following raw materials in parts by weight: 200 parts of edible fungus dregs, 200 parts of water, 35 parts of durian shells, 30 parts of Chinese herbal medicines, and 25 parts of lobster shells , 22 parts of poultry manure, 20 parts of acacia leaves, 16 parts of ash vegetables, 10 parts of fish scale powder, 1.4 parts of Trichoderma and 1 part of enzyme bacteria, of which,

[0081] The Trichoderma consists of the following raw materials in parts by weight: 10 parts of Trichoderma viride, 10 parts of Trichoderma longibrachiata and 10 parts of Trichoderma harsetii; the Chinese herbal medicine consists of the following raw materials in parts by weight: Duckweed Grass 25 parts, camphor leaves 23 parts, astragalus 22 parts, calamus 15 parts and mint 10 parts.

[0082] In the bio-organic fertilizer produced with edible fungus residue as the main ingredient, the effective live...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com