Multi-responsive pNIPAAm (poly(N-isopropylacrylamide))/(mPEG-g-CMCS) (methoxy polyethylene glycol-g-carboxymethyl chitosan) aquagel

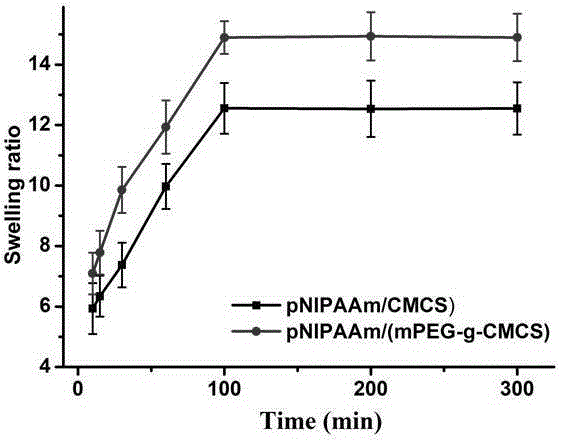

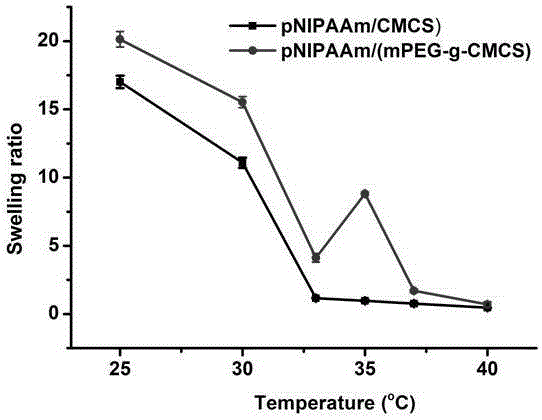

A mpeg-g-cmcs, responsive technology, applied in the field of multiple responsive pNIPAAm/hydrogel and its preparation, can solve the problems of low swelling degree of hydrogel, and achieve cheap raw materials, short operation period and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

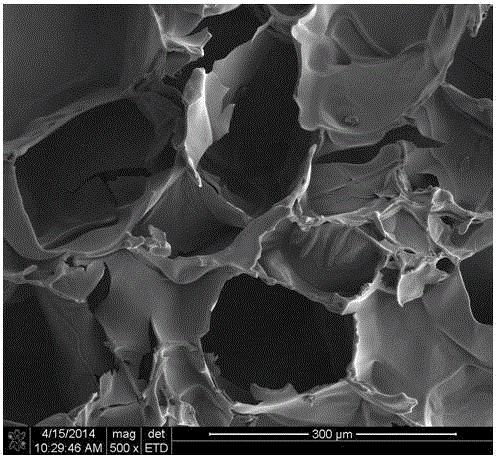

Image

Examples

Embodiment 1

[0026] 1) Dissolve 10.00gmPEG in 30mLDMSO and 2mL chloroform, and pass argon for 30min;

[0027] 2) Add 5 mL of acetic anhydride to the solution in 1), and react for 10 hours; pour the reaction solution into anhydrous ether for precipitation for 3 times, and obtain a white solid formylated mPEG;

[0028] 3) Dissolve 1.00g of CMCS and 2.77g of formylated mPEG, adjust the pH to 6.5, and pass argon for 30 minutes;

[0029] 4) 0.57gNaBH 4 Add the solution in 3) and react for 18h. Dialyzed for 3 days, freeze-dried to obtain mPEG-g-CMCS;

[0030] 5) Dissolve 4.00g NIPAAm in 50mL water;

[0031] 6) Add 0.08g BIS to the solution in 5), shake to dissolve;

[0032] 7) 0.40gmPEG-g-CMCS. Add the solution in 5) and shake to dissolve;

[0033] 8) Pass argon for 30 minutes to the solution in 7), and seal after removing oxygen;

[0034] 9) Put the solution in 8) in a refrigerator at 4°C for 1 hour, add 0.08g APS and 0.02g TEMED, and react at room temperature for 24 hours;

[0035] 10)...

Embodiment 2

[0037] 1) Dissolve 10.00gmPEG in 30mLDMSO and 2mL chloroform, and pass argon for 30min;

[0038] 2) Add 5mL of acetic anhydride to the solution in 1), and react for 10h. The reaction solution was poured into anhydrous ether for precipitation 3 times to obtain a white solid formylated mPEG;

[0039] 3) Dissolve 1.00g of CMCS and 2.77g of formylated mPEG, adjust the pH to 6.5, and pass argon for 30 minutes;

[0040] 4) 0.57gNaBH 4 Add the solution in 3) and react for 18h. Dialyzed for 3 days, freeze-dried to obtain mPEG-g-CMCS;

[0041] 5) Dissolve 4.00g NIPAAm in 50mL water;

[0042] 6) Add 0.08g BIS to the solution in 5), shake to dissolve;

[0043] 7) 0.6gmPEG-g-CMCS. Add the solution in 5) and shake to dissolve;

[0044] 8) Pass argon for 30 minutes to the solution in 7), and seal after removing oxygen;

[0045] 9) Put the solution in 8) in a refrigerator at 4°C for 1 hour, add 0.08g APS and 0.02g TEMED, and react at room temperature for 24 hours;

[0046] 10) Soak th...

Embodiment 3

[0048] 1) Dissolve 10.00gmPEG in 30mLDMSO and 2mL chloroform, and pass argon for 30min;

[0049] 2) Add 5mL of acetic anhydride to the solution in 1), and react for 10h. The reaction solution was poured into anhydrous ether for precipitation 3 times to obtain a white solid formylated mPEG;

[0050] 3) Dissolve 1.00g of CMCS and 2.77g of formylated mPEG, adjust the pH to 6.5, and pass argon for 30 minutes;

[0051] 4) 0.57gNaBH 4 Add the solution in 3) and react for 18h. Dialyzed for 3 days, freeze-dried to obtain mPEG-g-CMCS;

[0052] 5) Dissolve 4.00g NIPAAm in 50mL water;

[0053] 6) Add 0.08g BIS to the solution in 5), shake to dissolve;

[0054] 7) Add 0.8gmPEG-g-CMCS to the solution in 5), shake to dissolve;

[0055] 8) Pass argon for 30 minutes to the solution in 7), and seal after removing oxygen;

[0056] 9) Put the solution in 8) in a refrigerator at 4°C for 1 hour, add 0.08g APS and 0.02g TEMED, and react at room temperature for 24 hours;

[0057] 10) Soak th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com