Montmorillonite composite flame retardant and preparation method thereof

A technology of composite flame retardant and montmorillonite, which is applied in the field of flame retardants, can solve the problems of affecting the synergistic flame retardant effect and difficulty in uniform dispersion, and achieve the effects of reducing secondary hazards, wide application range, and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

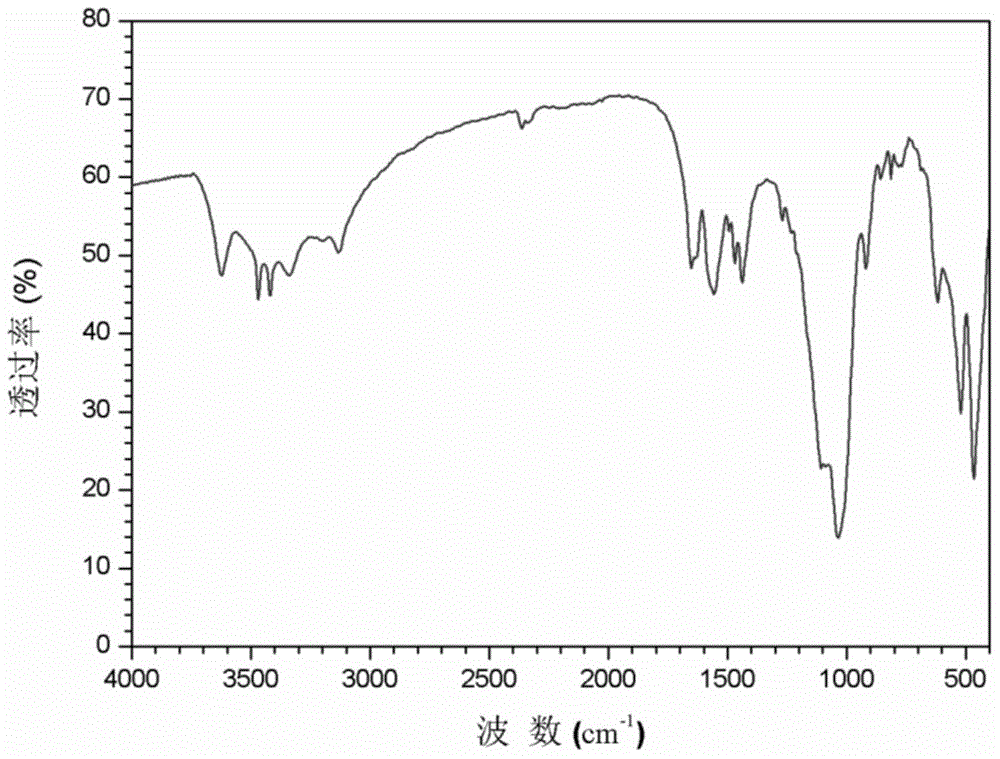

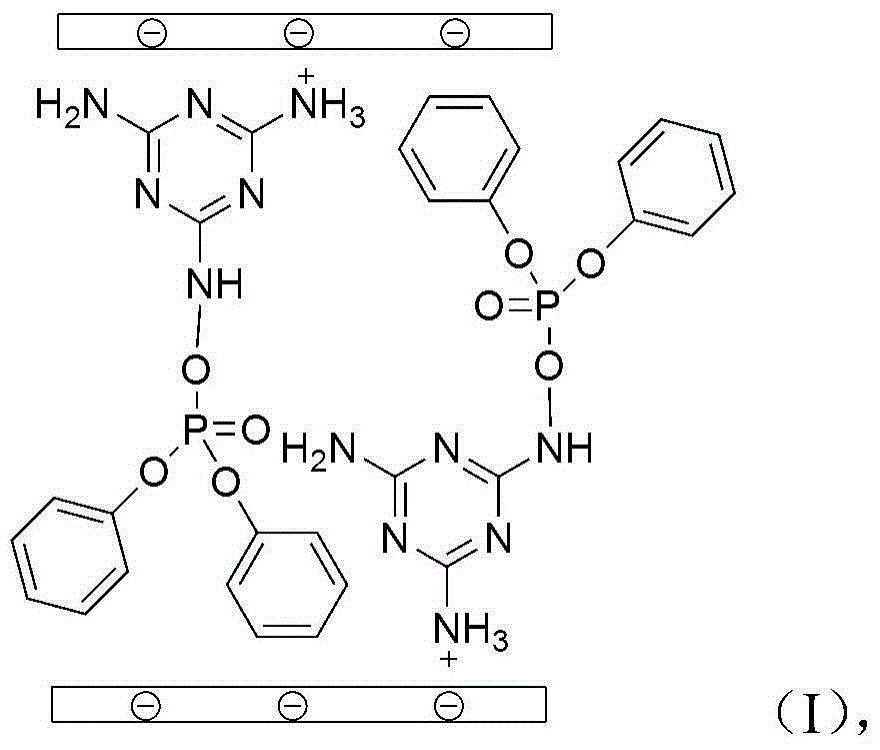

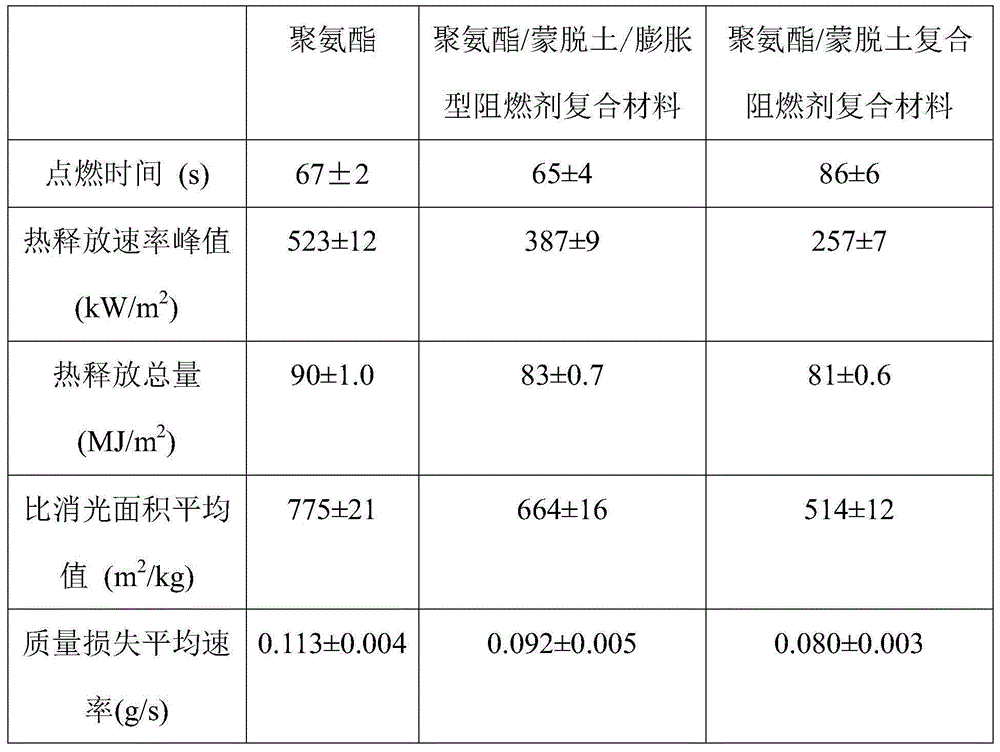

Method used

Image

Examples

Embodiment 1

[0027] Dissolve 6.4g of melamine in 508mL of hydrochloric acid with a concentration of 0.1mol / L, and stir for 1 hour to obtain melamine hydrochloride. Add 800mL of distilled water and 80g of montmorillonite in a 2L stainless steel reaction kettle, heat to 80°C and stir vigorously for 2 hours, add the above-mentioned melamine hydrochloride, stir vigorously at 80°C for 12 hours, filter the obtained product with 80°C distilled water Washing several times until the filtered water does not contain halide ions or nitrate ions, and vacuum-drying the obtained solid at 70° C. to constant weight to obtain melamine-modified montmorillonite.

[0028] Add 8.64g of melamine-modified montmorillonite to 300mL of toluene, ultrasonically disperse it for 30 minutes, then transfer it to a dry four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and add 13.6g of it dropwise at room temperature The mixed solution of diphenoxyphosphoryl chlor...

Embodiment 2

[0030] Dissolve 0.96 g of melamine in 90 mL of hydrochloric acid with a concentration of 0.1 mol / L, and stir for 1 hour to obtain melamine hydrochloride. Add 800mL of distilled water and 97g of montmorillonite into a 2L stainless steel reaction kettle, heat to 80°C and stir vigorously for 2 hours, add the above-mentioned melamine hydrochloride, stir vigorously at 80°C for 12 hours, and filter the obtained product with 80°C distilled water Washing several times until the filtered water does not contain halide ions or nitrate ions, and vacuum-drying the obtained solid at 70° C. to constant weight to obtain melamine-modified montmorillonite.

[0031] Add 9.796g of melamine-modified montmorillonite to 300mL of toluene, ultrasonically disperse it for 30 minutes, then transfer it to a dry four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and add 2.04g of it dropwise at room temperature The mixed solution of diphenoxyphosph...

Embodiment 3

[0033] Dissolve 9.6 g of melamine in 180 mL of hydrochloric acid with a concentration of 0.5 mol / L, and stir for 1 hour to obtain melamine hydrochloride. Add 800mL of distilled water and 70g of montmorillonite in a 2L stainless steel reaction kettle, heat to 80°C and stir vigorously for 2 hours, add the above-mentioned melamine hydrochloride, stir vigorously at 80°C for 12 hours, and filter the product obtained with 80°C distilled water Washing several times until the filtered water does not contain halide ions or nitrate ions, and vacuum-drying the obtained solid at 70° C. to constant weight to obtain melamine-modified montmorillonite.

[0034] Add 7.96g of melamine-modified montmorillonite to 200mL of toluene, ultrasonically disperse it for 30 minutes, then transfer it to a dry four-necked flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel, and add 20.4g of it dropwise at room temperature The mixed solution of diphenoxyphosphory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com