Preparation method for antibacterial cellulose sponge material

A technology of antibacterial fiber and sponge, which is applied in the field of preparation of antibacterial fiber sponge materials, can solve the problems of poor antibacterial effect, cellulose sponge does not have biologically active antibacterial components, etc., and achieves high conversion rate, rich raw materials, and rapid regeneration cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

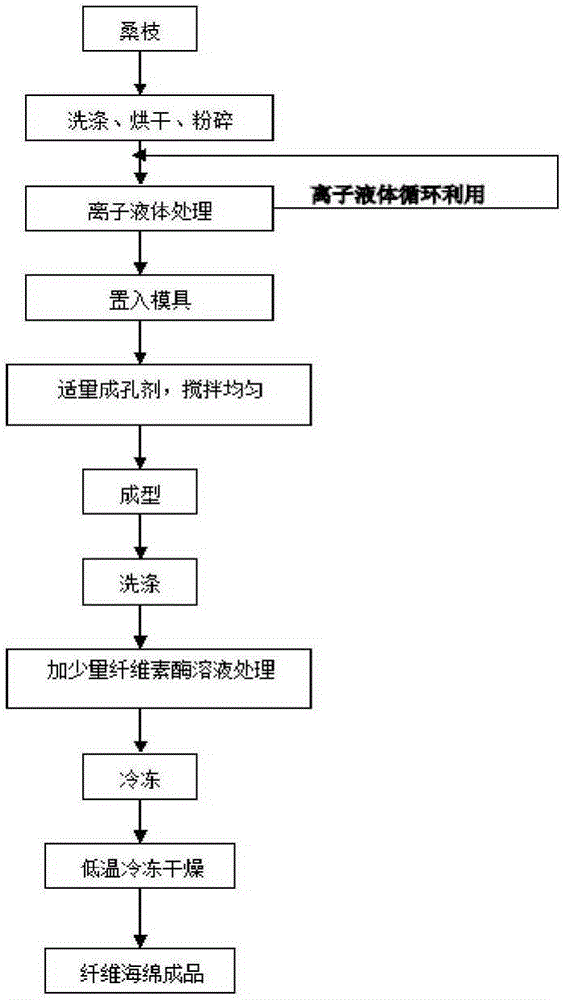

[0029] A kind of preparation method of antibacterial fiber sponge material of the present invention, preparation process is as follows figure 1 shown, including the following steps:

[0030] (1) Get the mulberry branch and wash away the sediment with tap water, dry it at 78°C for 24 hours, grind the mulberry branch into mulberry branch powder, and pass the mulberry branch powder through a 10-mesh sieve to obtain a mulberry branch powder with a particle size of about 2mm;

[0031] (2) Weigh 0.334g of mulberry branch powder, add 5g of ([EMIM][Ac]) and mix uniformly, and heat the uniformly mixed solution to 100°C in a collector-type constant temperature heating magnetic stirrer until dissolved, Heating for 40min;

[0032] (3) Inject the mixture into the pre-prepared mold, weigh 20g of anhydrous sodium sulfate, add it into it and stir continuously until the mixture is uniform, and mold it at 90°C for 1 hour to obtain a semi-finished product;

[0033] (4) Wash the semi-finished p...

Embodiment 2

[0036] (1) Get the mulberry branch and wash away the sediment with tap water, dry it at 78°C for 24 hours, grind the mulberry branch into mulberry branch powder, and pass the mulberry branch powder through a 10-mesh sieve to obtain a mulberry branch powder with a particle size of about 2mm;

[0037] (2) Weigh 0.2g of mulberry branch powder, add 4g of ([EMIM][DEP]) and mix evenly, and heat the uniformly mixed solution to 100°C in a collector type constant temperature heating magnetic stirrer until it dissolves, Heating for 1h;

[0038] (3) Inject the mixture into the pre-prepared mold, weigh 12.6g of anhydrous sodium sulfate, add it into it and stir continuously until the mixture is uniform, and mold it at 90°C for 1 hour to obtain a semi-finished product;

[0039] (4) Wash the semi-finished product with distilled water at 50°C to remove the pore-forming agent and excess solvent, then take 10ml of the prepared cellulase solution with a concentration of 0.0025g / ml and add it to ...

Embodiment 3

[0042] (1) Get the mulberry branch and wash away the sediment with tap water, dry it at 78°C for 24 hours, grind the mulberry branch into mulberry branch powder, and pass the mulberry branch powder through a 10-mesh sieve to obtain a mulberry branch powder with a particle size of about 2mm;

[0043](2) Weigh 0.3g of mulberry powder, add 6g of [AMIM][Cl] and mix evenly, heat the mixed solution to 80°C in a collector-type constant temperature heating magnetic stirrer until dissolved, and heat for 30min ;

[0044] (3) Inject the mixture into the pre-prepared mold, weigh 25.2g of anhydrous sodium chloride, add it and stir continuously until the mixture is uniform, and mold at 90°C for 1.5h to form a semi-finished product;

[0045] (4) Wash the semi-finished product with ethanol at 50°C to remove the pore-forming agent and excess solvent, then take 10ml of the cellulase solution with a concentration of 0.0025g / ml and add it to the mold, and add buffer to adjust the pH to 6 , react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com