Water-based environment-friendly rust removal and prevention film covering liquid and production process thereof

An environmentally friendly, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of short salt spray resistance, short shelf life, peeling and powdering, etc., and achieve long water and salt spray resistance, strong metal adhesion, and anti-corrosion. strong rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

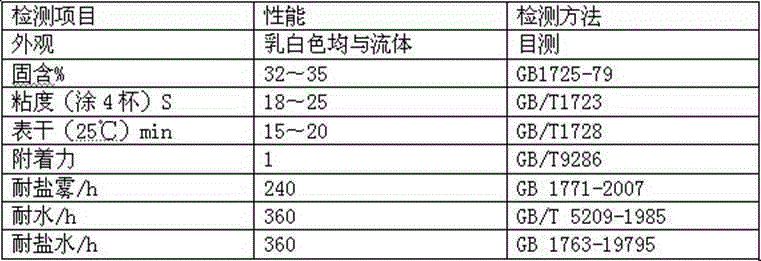

Image

Examples

specific Embodiment 1

[0022] A water-based environment-friendly rust removal and anti-rust coating solution, the water-based environment-friendly rust removal and anti-rust coating solution is composed of the following components in parts by weight:

[0023] 20 parts deionized water

[0024] Rust remover and anti-rust agent 5 parts

[0025] Coalescing aid 2 parts

[0026] Antifreeze 2 parts

[0027] 0.3 parts of defoamer

[0028] 40 parts of film-forming substance

[0029] Substrate wetting agent 0.3 parts.

[0030] The rust-removing and anti-rust agent adopts tannic acid.

[0031] The film-forming aid adopts alcohol ester twelve.

[0032] The antifreeze uses ethanol.

[0033] The film-forming substance is RPW402 vinyl multi-component copolymerized vinylidene chloride emulsion of Nantong Rui Puier Biological Engineering Co., Ltd., with a solid content of 40%.

[0034] The defoamer adopts Hemings DF1181.

[0035] The substrate wetting agent adopts Hemings W77.

[0036] A production process...

specific Embodiment 2

[0037] A water-based environment-friendly rust removal and anti-rust coating solution, the water-based environment-friendly rust removal and anti-rust coating solution is composed of the following components in parts by weight:

[0038] 30 parts deionized water

[0039] Rust remover and anti-rust agent 15 parts

[0040] 8 parts of film-forming aid

[0041] Antifreeze 4 parts

[0042] 1 part defoamer

[0043] 70 parts of film-forming substance

[0044] Substrate wetting agent 1 part.

[0045] The rust-removing and anti-rust agent adopts tannic acid.

[0046] The film-forming aid dipropylene glycol methyl ether.

[0047] The antifreeze uses ethylene glycol.

[0048] The film-forming material adopts RPW402 vinyl multi-component copolymerized vinylidene chloride emulsion of Nantong Rui Puier Biological Engineering Co., Ltd., with a solid content of 40%.

[0049] The defoamer uses BASF 2410.

[0050] The substrate wetting agent adopts Hemings W469.

[0051] A production p...

specific Embodiment 3

[0052] A water-based environment-friendly rust removal and anti-rust coating solution, the water-based environment-friendly rust removal and anti-rust coating solution is composed of the following components in parts by weight:

[0053] 24 parts deionized water

[0054] Rust remover and anti-rust agent 12 parts

[0055] 6 parts of film-forming aid

[0056] 3 parts of antifreeze

[0057] 0.7 parts of defoamer

[0058] 60 parts of film-forming substance

[0059] 0.8 parts of substrate wetting agent.

[0060] The rust-removing and anti-rust agent adopts tannic acid.

[0061] The film-forming aid adopts dipropylene glycol butyl ether.

[0062] Described antifreeze adopts propylene glycol.

[0063] The film-forming substance is RPW402 vinyl multi-component copolymerized vinylidene chloride emulsion of Nantong Rui Puier Biological Engineering Co., Ltd., with a solid content of 40%.

[0064] The defoamer adopts Rhodia DN-642.

[0065] The substrate wetting agent adopts Hemings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com