Method for preparing Fe-Al-Cr alloy layer through multi-arc ion aluminum plating, arc-added glow discharge chromizing and recoil ion implantation

A multi-arc ion plating and arc glow technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc. problem, to achieve the effect of uniform distribution of elements and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Present embodiment 1 is implemented under the following implementation conditions and technical requirements:

[0026] First, the surface of 45 steel is ground and polished to make the surface roughness Ra reach 0.5 μm, and the ultrasonic time is 30 minutes.

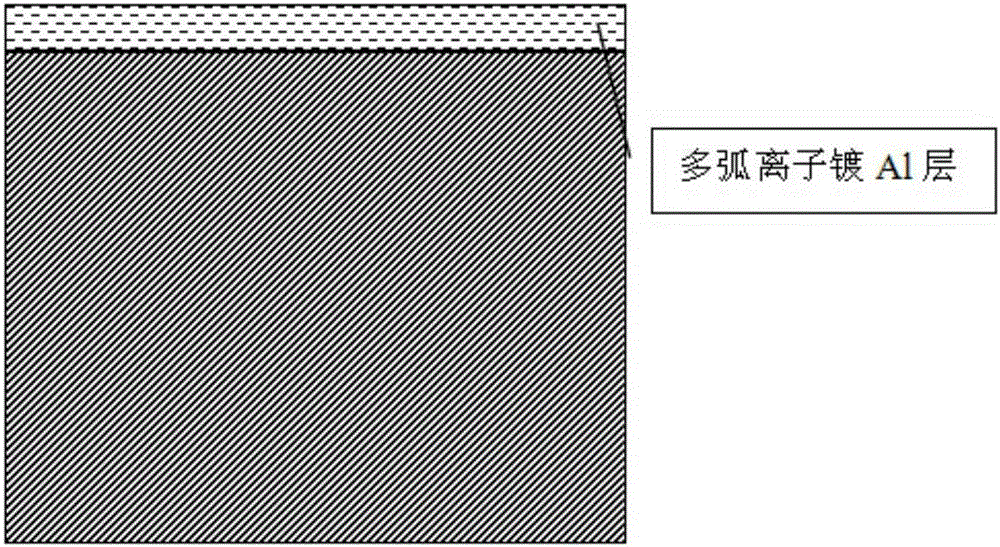

[0027] Then use multi-arc ion plating technology to plate Al on the surface of 45 steel, in which the target material is 99.99% Al. The specific process parameters selected are Ar gas flow rate of 25SCCM, working pressure of 0.4Pa, target source current of 50A, substrate negative bias voltage of -25V, deposition temperature of 100°C, deposition time of 20min, and deposition rate of 0.2μm / min .

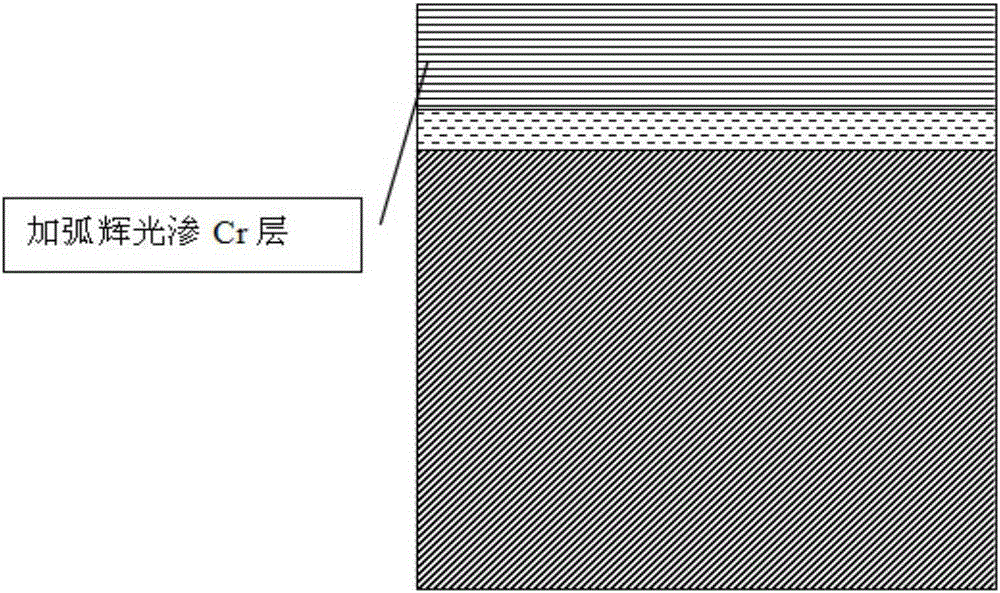

[0028] Then, the outer surface of the multi-arc ion-plated Al layer obtained in the previous step is subjected to Cr infiltration treatment by using the arc-added glow technology, and the target material is 99.99% Cr. The specific process parameters selected are Ar gas pressure of 25Pa, arc current of 60A, pole spacing o...

Embodiment 2

[0032] This embodiment 2 is implemented under the following implementation conditions and technical requirements:

[0033] First, the surface of T8 steel was ground and polished to make the surface roughness Ra reach 2 μm, and the ultrasonic time was 30 minutes.

[0034] Al was plated on the surface of T8 steel by multi-arc ion plating technology, and the target material was 99.99% Al. The specific process parameters selected are Ar gas flow rate of 35SCCM, working pressure of 0.6Pa, target source current of 60A, substrate negative bias voltage of -35V, deposition temperature of 120°C, deposition time of 40min, and deposition rate of 0.4μm / min .

[0035] Then, the outer surface of the multi-arc ion-plated Al layer obtained in the previous step is subjected to Cr infiltration treatment by using the arc-added glow technology, and the target material is 99.99% Cr. The selected process parameters are Ar gas pressure of 45Pa, arc current of 80A, pole spacing of 140mm, bias voltag...

Embodiment 3

[0039] This embodiment 3 is implemented under the following implementation conditions and technical requirements:

[0040] First, the surface of 304 stainless steel is ground and polished to make the surface roughness Ra reach 1 μm, and the ultrasonic time is 30 minutes.

[0041] Then use multi-arc ion plating technology to plate Al on the surface of 304 stainless steel, wherein the target material is 99.99% Al. The specific process parameters selected are Ar gas flow rate of 30SCCM, working pressure of 0.5Pa, target source current of 55A, substrate negative bias voltage of -45V, deposition temperature of 150°C, deposition time of 30min, and deposition rate of 0.3μm / min .

[0042]Then, the outer surface of the multi-arc ion-plated Al layer obtained in the previous step is subjected to Cr infiltration treatment by using the arc-added glow technology, and the target material is 99.99% Cr. The selected process parameters are Ar gas pressure of 35Pa, arc current of 70A, pole spa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific wear rate | aaaaa | aaaaa |

| Specific wear rate | aaaaa | aaaaa |

| Specific wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com