Preparation method of nanocellulose/oxidized regenerated cellulose composite hemostatic material

A technology of nanocellulose and regenerated cellulose, which is applied in the field of biomedical composite materials, can solve the problems of slow hemostatic rate and small improvement in hemostatic performance, and achieve the effects of reducing hemostatic time, improving hemostatic performance and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Embodiment 1: The preparation method of the nanocellulose / oxidized regenerated cellulose composite hemostatic material provided in this embodiment is carried out according to the following steps:

[0034] First, the preparation of nanocellulose:

[0035] ① Take 1.0~5.0g of microcrystalline cellulose and 45mL of sulfuric acid solution with a certain mass fraction (the mass ratio between the two is about 1:15~45) and mix them in a clean beaker, turn on magnetic stirring, and at a temperature of 30~50℃ The reaction was carried out under the condition of water bath for 1~3h.

[0036] ② Pour the reaction solution into 400-500 ml of deionized water to complete the reaction, let it stand, and remove the supernatant. The suspension was washed 4-6 times by centrifugation in deionized water. A pH value of 5-7 was measured. After ultrasonic treatment for 15-30 min, the sol was put into a dialysis bag for purification treatment, and the outer dialysis fluid was deionized water. ...

specific Embodiment approach 2

[0061] Specific embodiment 2: The preparation method of the nanocellulose / oxidized regenerated cellulose composite hemostatic material provided by this embodiment is carried out according to the following steps:

[0062] First, the preparation of nanocellulose:

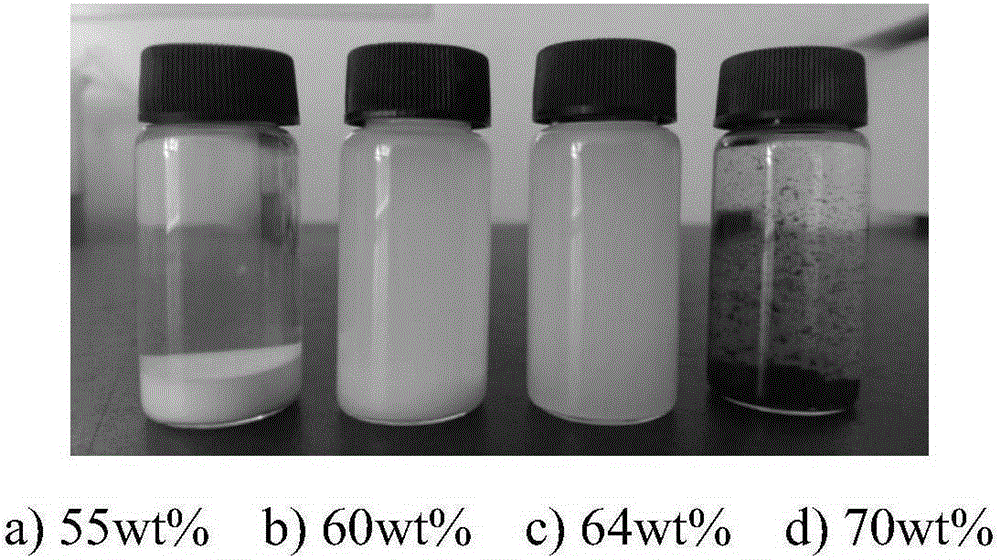

[0063] ① Mix 1.0g of microcrystalline cellulose and 45mL of sulfuric acid solution with a certain mass fraction (the ratio between the two is about 1:15) in a clean beaker, turn on magnetic stirring, and react in a water bath at 40°C for 2h. The effect of treating microcrystalline cellulose with different mass fractions of sulfuric acid is as follows figure 1 shown. Depend on figure 1 It can be seen that when the sulfuric acid concentration is 64 wt.%, a uniformly dispersed nanocellulose suspension is obtained.

[0064] ②Pour the reaction solution into 10 times the volume of deionized water to complete the reaction, let it stand, and remove the supernatant. The suspension was washed 5 times by centrifugation in de...

specific Embodiment approach 3

[0083] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the amount of the microcrystalline cellulose is 3 g. Others are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com