Ammonia gas sensor and preparation technology thereof

An ammonia gas sensor and a preparation process technology, applied in directions such as material resistance, can solve problems such as unstable response, and achieve the effects of fewer preparation steps, high conductivity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

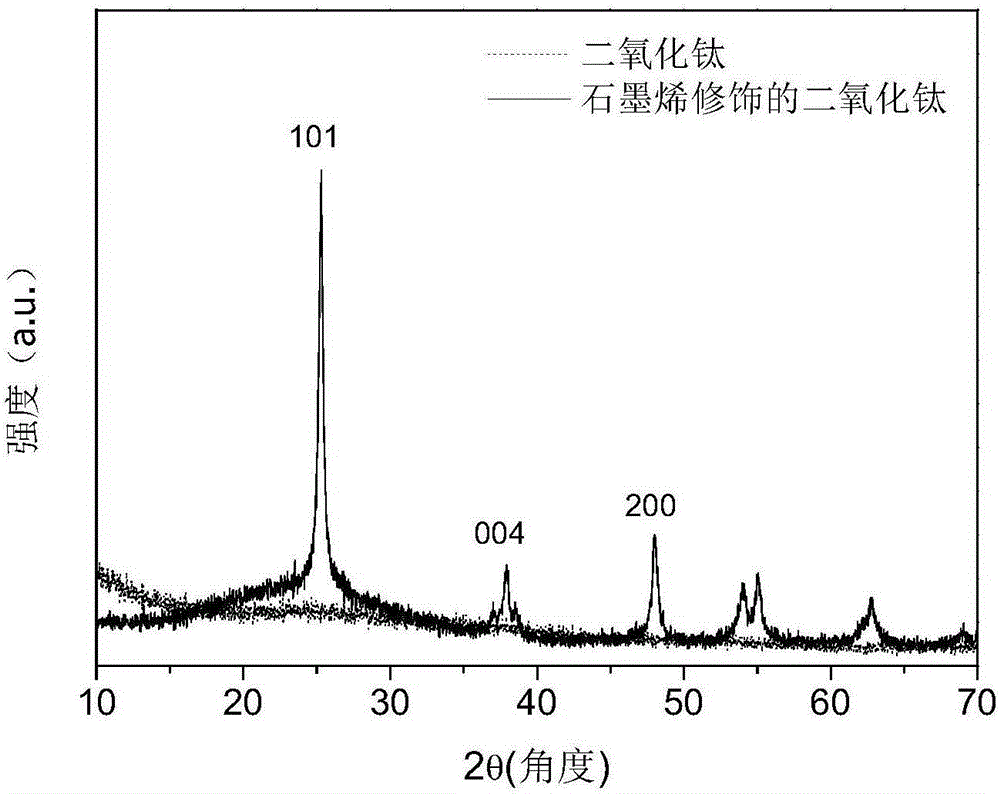

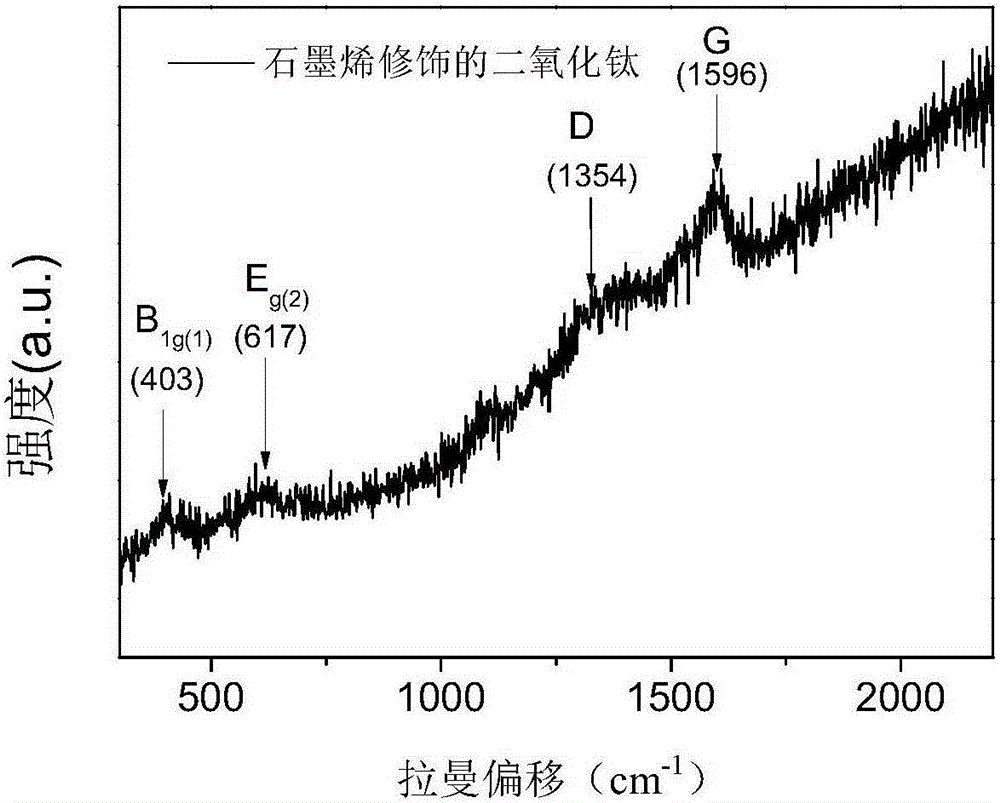

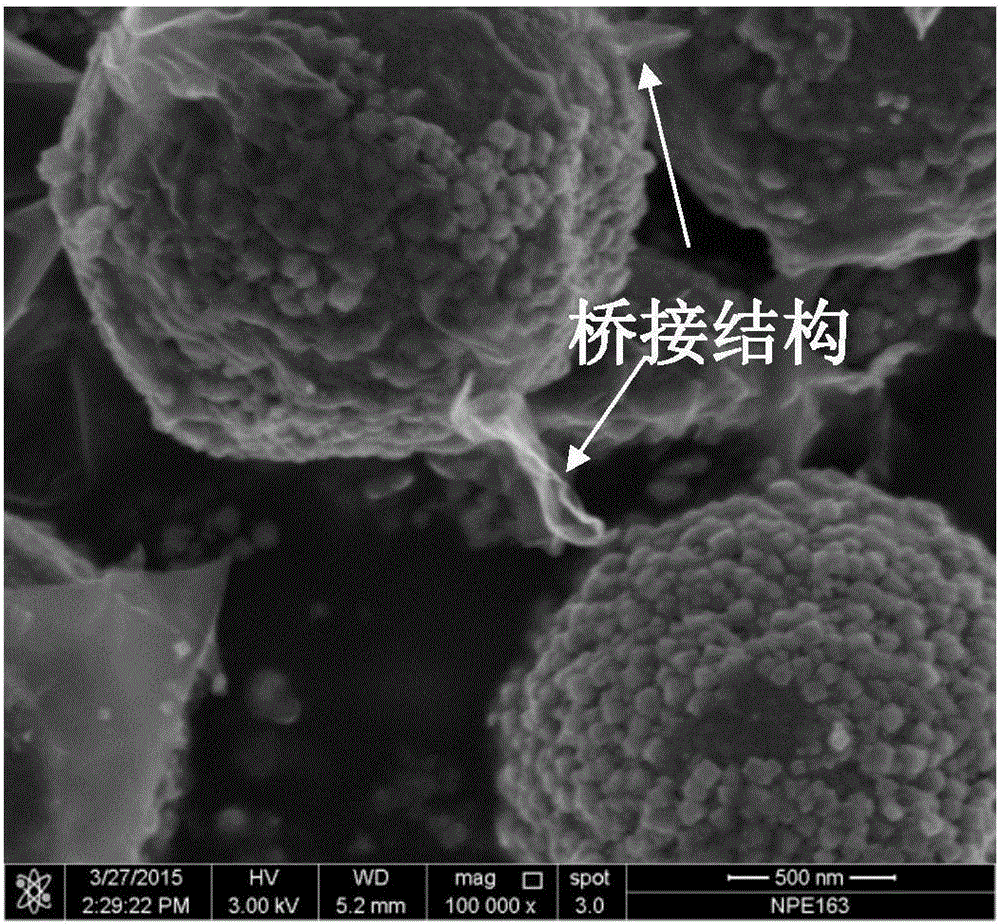

[0036] The ammonia gas sensor includes a gas-sensing material and a substrate, the gas-sensing material is evenly coated on the surface of the substrate, the composition of the gas-sensing material includes graphene-modified titanium dioxide composite nanoparticles with a bridging structure, and the coating thickness of the gas-sensing material is 0.4- 0.5 μm. Graphene-modified titanium dioxide composite nanoparticles with a bridging structure, including graphene and titanium dioxide, the bridging structure means that graphene is bridged between the titanium dioxide, and the graphene accounts for 4.7% of the mass fraction of the composite nanoparticles, The preparation method comprises the following steps:

[0037] Step 1, prepare titanium dioxide microsphere particles: dissolve 5.3g of hexadecylamine (hexadecylamine) in 800ml of absolute ethanol (ethanol), then add 3.2ml of KCl (0.1mol / L) solution, in a water bath stirrer at room temperature Stir, add 17.6ml of isopropyl tit...

Embodiment 2

[0047] The ammonia gas sensor comprises a gas-sensitive material and a substrate, the gas-sensitive material is evenly coated on the surface of the substrate, the gas-sensitive material composition includes graphene-modified titanium dioxide composite nanoparticles with a bridging structure, the gas-sensitive material The coating thickness is 0.4-0.5 μm. Graphene-modified titanium dioxide composite nanoparticles with a bridging structure, including graphene and titanium dioxide, the bridging structure means that graphene is bridged between the titanium dioxide, and the graphene accounts for 1.9% of the mass fraction of the composite nanoparticles, The preparation method comprises the following steps:

[0048] Step 1, prepare titanium dioxide microsphere particles: dissolve 5.3g of hexadecylamine (hexadecylamine) in 800ml of absolute ethanol (ethanol), then add 3.2ml of KCl (0.1mol / L) solution, in a water bath stirrer at room temperature Stir, add 17.6ml of isopropyl titanate ...

Embodiment 3

[0055] A novel ammonia gas sensor, comprising a gas-sensing material and a substrate, the gas-sensing material is evenly coated on the surface of the substrate, the gas-sensing material composition includes graphene-modified titanium dioxide composite nanoparticles with a bridging structure, the The coating thickness of the gas-sensitive material is 0.4-0.5 μm. Graphene-modified titanium dioxide composite nanoparticles with a bridging structure, including graphene and titanium dioxide, the bridging structure means that graphene is bridged between the titanium dioxide, and the graphene accounts for 9.0% of the mass fraction of the composite nanoparticles, The preparation method comprises the following steps:

[0056] Step 1, prepare titanium dioxide microsphere particles: dissolve 5.3g of hexadecylamine (hexadecylamine) in 800ml of absolute ethanol (ethanol), then add 3.2ml of KCl (0.1mol / L) solution, in a water bath stirrer at room temperature Stir, add 17.6ml of isopropyl ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com