A kind of preparation method of iron-based metal soft magnetic powder core

A soft magnetic powder core, iron-based metal technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of low green body strength, unstable magnetic properties, and low pressing density of metal soft magnetic powder cores , to achieve uniform density distribution, easy green body demoulding, and the effect of expanding the field of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

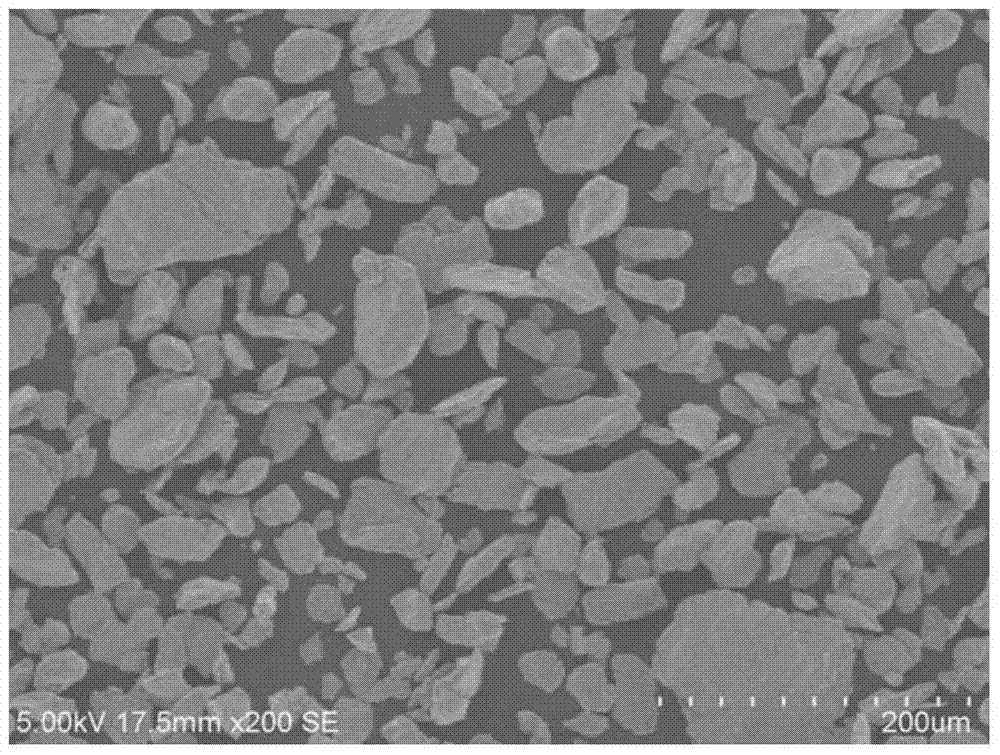

[0027] A kind of preparation method of novel FeSi6.5 metal soft magnetic powder core, this method is carried out by the following steps: first select the flaky metal FeSi6.5 powder (powder average particle size is 75 μm) prepared by high-energy ball milling as raw material, as figure 1 Shown is the SEM topography of the flaky powder used, and it was annealed at 750°C for 5 hours to form a (110) texture inside. The phosphoric acid solution that the concentration of magnetic powder weight 2wt% is 10% (mass percentage) joins in the middle of magnetic powder, and adds polyvinyl alcohol dispersant, and addition is 0.2% (mass percentage) of magnetic powder weight, and inorganic insulating agent SiO 2 、Al 2 o 3 , Kaolin is added therein for insulation coating, and the addition amounts are respectively 0.5%, 0.8% and 0.45% of the weight of the magnetic powder. Dry the passivated and insulating powders at a temperature of 60° C. for 3 hours. The dried metal powder is pressed into a ...

Embodiment 2

[0029] A kind of preparation method of novel FeSi4Ni metal soft magnetic powder core, this method is carried out according to the following steps: first select sheet-shaped metal FeSi4Ni powder (average particle size of powder is 50 μm) as raw material, and carry out 800 ℃, 4.5h annealing treatment to it, and make A (110) texture is formed inside it. The phosphoric acid solution that the concentration of magnetic powder weight 2.5wt% is 10% (mass percentage) joins in the middle of magnetic powder, and adds polyvinyl alcohol dispersant, and addition is 1% (mass percentage) of magnetic powder weight, then inorganic insulating agent SiO 2, talcum powder, and kaolin are added therein for insulation coating, and the addition amounts are 0.7%, 0.6% and 0.25% of the weight of the magnetic powder respectively. Dry the passivated and insulating powders at a temperature of 100° C. for 2.5 hours. The dried metal powder is pressed into a magnetic powder core blank, and the release agent ...

Embodiment 3

[0031] A kind of preparation method of novel FeSi6Cr5 metal soft magnetic powder core, this method is carried out according to the following steps: first select sheet-like metal FeSi6Cr5 powder (the average particle size of powder is 100 μm) as raw material, and carry out 900 ℃, 3h annealing treatment to it, and make it A (110) texture is formed inside. The phosphoric acid solution that the concentration of magnetic powder weight 3wt% is 8% (mass percentage) joins in the middle of magnetic powder, and adds polyvinyl alcohol dispersant, and addition is 2% (mass percentage) of magnetic powder weight, and inorganic insulating agent SiO 2 , mica powder and kaolin are added therein for insulation coating, and the addition amounts are 0.3%, 0.7% and 0.55% of the weight of the magnetic powder respectively. Dry the passivated and insulating powders at a temperature of 120° C. for 1 hour. The dried metal powder is pressed into a magnetic powder core blank, and the release agent is zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com