Semiconductor cut-out switch based on silicon carbide, and manufacturing method thereof

A circuit breaker and silicon carbide technology, which is applied in the direction of semiconductor devices, circuits, electrical components, etc., can solve the problems of off-state characteristic loss and pump characteristic loss, and achieve reduced switching power consumption, low on-resistance, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

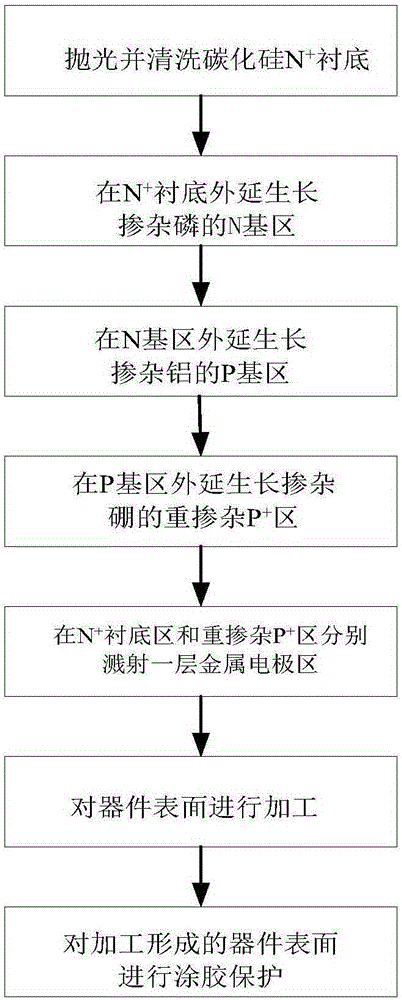

Method used

Image

Examples

Embodiment 1

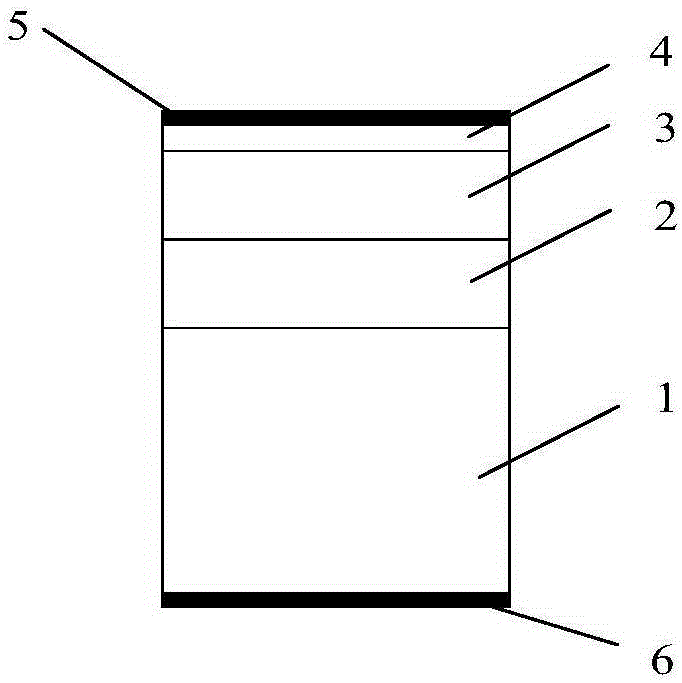

[0063] In Example 1, N + The thickness of the substrate is 300 μm; the concentration of phosphorus doped in the N base is 10 14 cm 3 , with a thickness of 10 μm; the concentration of doped aluminum in the P base region is 10 16 / cm 3 ~10 17 / cm 3 , and the concentration gradient is 9*10 14 / (cm 3 μm) incremental growth with a thickness of 100 μm; heavily doped P + region doped with boron at a concentration of 10 19 / cm 3 , with a thickness of 1 μm;

Embodiment 2

[0065] Example 2 according to figure 1 The illustrated process flow is used to complete the preparation of the silicon carbide-based semiconductor circuit breaker, the difference from Embodiment 1 is:

[0066] In step (2), the concentration of the N base region is controlled at 10 16 / cm 3 ~10 17 / cm 3 , and the concentration gradient is 9*10 14 / (cm 3 μm) incremental growth, with a thickness of 100 μm; under this parameter condition, when the switch PN junction is conducting forward, the accumulation of minority carriers on both sides of the space charge region, when the switch PN junction voltage reverses, can produce a large The reverse current realizes the SOS effect, which is beneficial to the miniaturization of the device;

[0067] And in step (3), the doping concentration of the P base region doped with aluminum is 10 14 / cm 3 ;

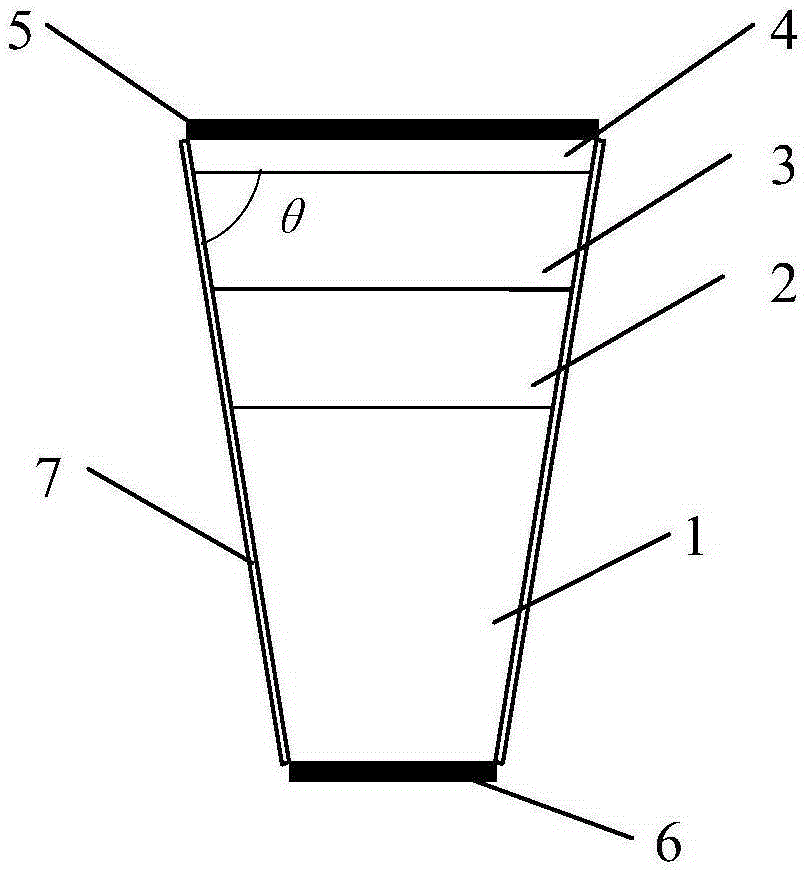

[0068] And in step (6), when the mesa is processed by mechanical cutting into an oblique angle, the PN junction is cut and penetrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com