Preparation method of spherical lithium-ion secondary battery cathode material vanadium phosphate monohydrate

A secondary battery and positive electrode material technology, applied in the field of electrochemistry, to achieve the effects of good wetting, high specific surface area, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of vanadium phosphate monohydrate, a positive electrode material for a spherical lithium-ion secondary battery, comprising the following steps:

[0024] 1) Change the H 3 PO 4 and VCl 3 According to the molar ratio of 3:1~5:1, add it into the polytetrafluoroethylene reactor, add water and stir to mix, adjust the pH value to 1.5~3.5 while stirring, then seal the polytetrafluoroethylene reactor, and stir for 45~50h ;

[0025] 2) Put the reaction kettle into the muffle furnace to heat up at a rate of 5°C / min. When the temperature rises to 150~200°C, keep it warm for 70~75h;

[0026] 3) Lower the reaction kettle to room temperature at a rate of 5°C / min to obtain a light green precipitate, wash and dry the obtained precipitate to obtain the target product VPO 4 ·H 2 O.

Embodiment 1

[0028] A preparation method of vanadium phosphate monohydrate, a positive electrode material for a spherical lithium-ion secondary battery, comprising the following steps:

[0029] 1) Change the H 3 PO 4 and VCl 3 According to the molar ratio of 4:1, add it into the polytetrafluoroethylene reactor, add water and stir to mix, adjust the pH value to 2.5 with methyltriethylammonium chloride while stirring, then seal the polytetrafluoroethylene reactor, stir 48h;

[0030] 2) Put the reaction kettle into the muffle furnace to heat up at a rate of 5°C / min. When the temperature rises to 200°C, keep it warm for 72 hours;

[0031] 3) Lower the reaction kettle to room temperature at a rate of 5°C / min to obtain a light green precipitate, wash the obtained precipitate with absolute ethanol, and then dry at 90°C to obtain the target product VPO 4 ·H 2 O;

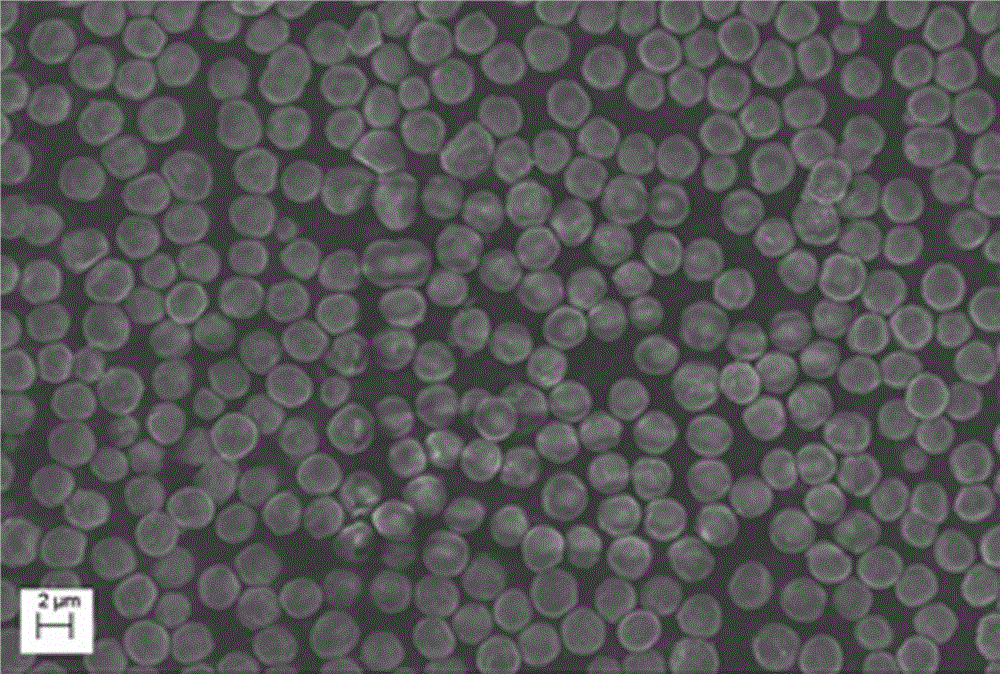

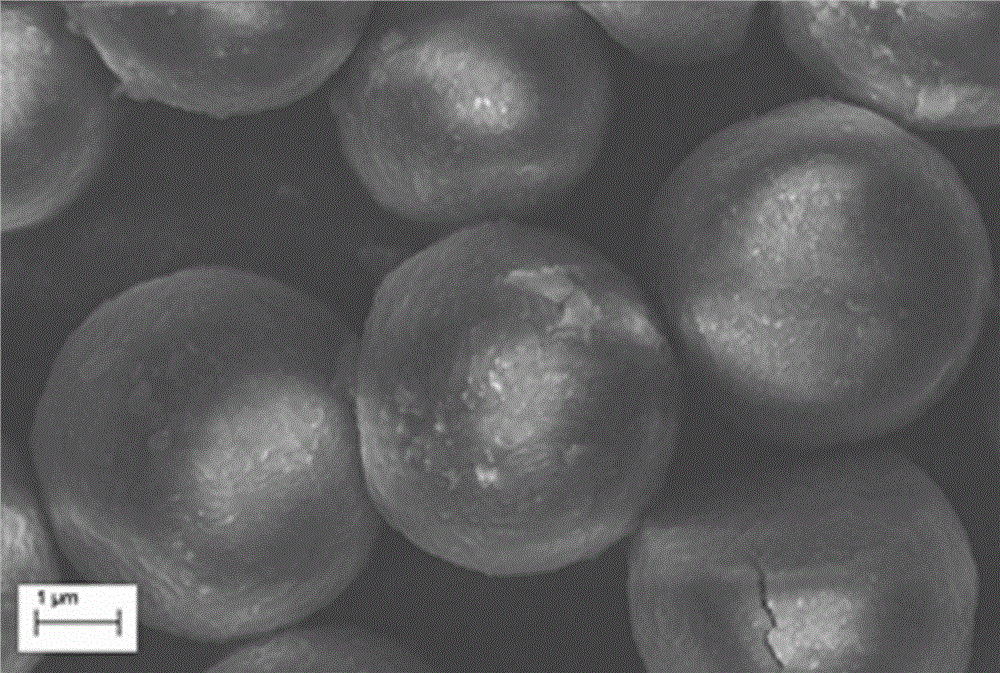

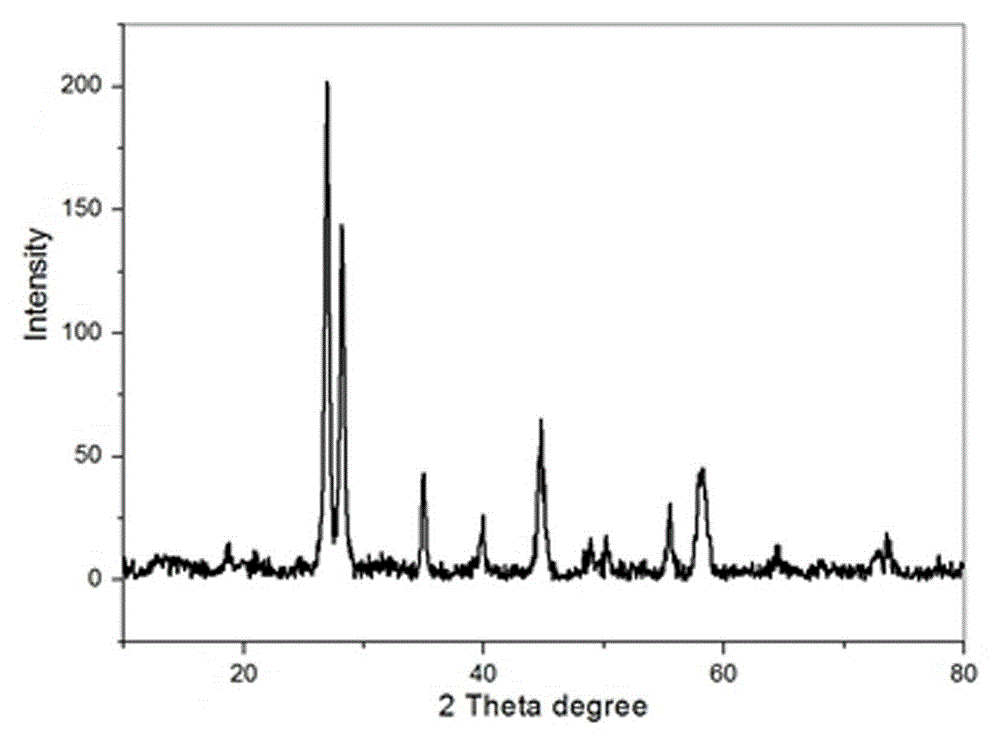

[0032] The SEM image of the obtained product is shown in figure 1 , figure 2 As shown, X-ray analysis such as image 3 As sho...

Embodiment 2

[0034] A preparation method of vanadium phosphate monohydrate, a positive electrode material for a spherical lithium-ion secondary battery, comprising the following steps:

[0035] 1) Change the H 3 PO 4 and VCl 3 According to the molar ratio of 3:1, add it into the polytetrafluoroethylene reactor, add water and stir to mix, adjust the pH value to 3.5 with methyltriethylammonium chloride while stirring, then seal the polytetrafluoroethylene reactor, stir 45h;

[0036] 2) Put the reaction kettle into the muffle furnace to heat up at a rate of 5°C / min. When the temperature rises to 150°C, keep it warm for 75h;

[0037] 3) Lower the reaction kettle to room temperature at a rate of 5°C / min to obtain a light green precipitate, wash the obtained precipitate with absolute ethanol, and then dry at 90°C to obtain the target product VPO 4 ·H 2 O.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com