A kind of preparation technology of microcrystalline cellulose ball core

A technology of microcrystalline cellulose pills and microcrystalline cellulose, which is applied in the field of preparation technology of microcrystalline cellulose pill cores, can solve the problems of low surface finish and roundness, reduced cellulose purity, influence of drug properties, etc. The effect of improving coating efficiency, low viscosity and reducing coating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

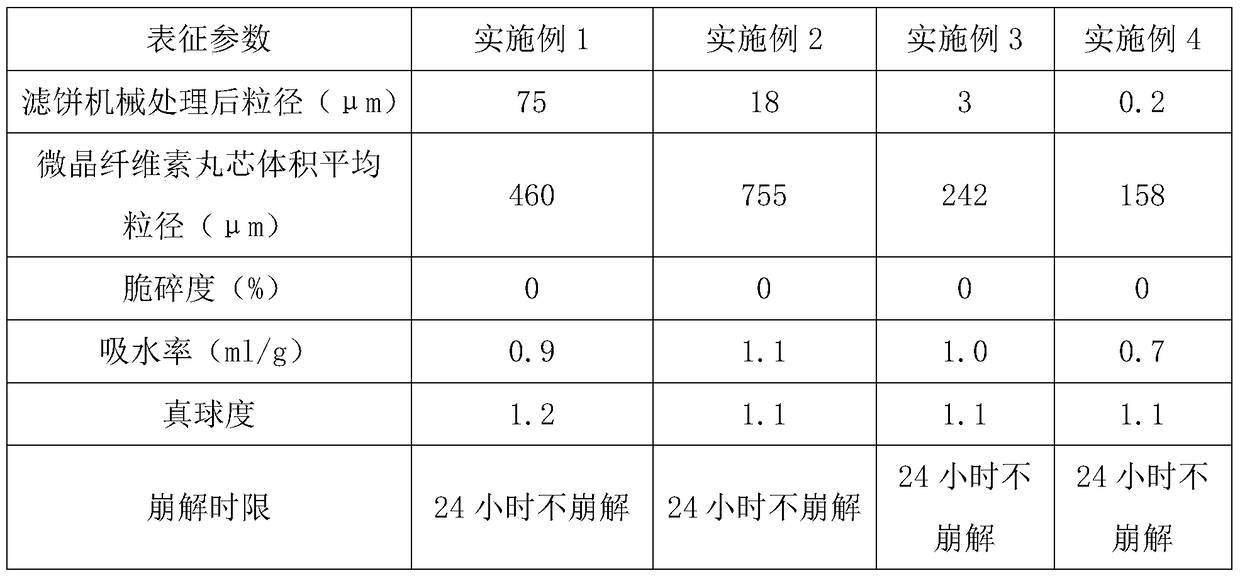

[0039]Commercially available paper pulp (purchased from Shandong Rizhao Senbo Pulp and Paper Co., Ltd.) was hydrolyzed for 60 minutes in a 0.1mol / L hydrochloric acid solution with a temperature of 100°C and a pressure of 0.5Mpa, and filtered and washed to obtain a filter with a solid content of 45wt%. cake. After stirring the filter cake for 1 hour with a mixing mixer (RW 28 type, manufactured by IKA), a microcrystalline cellulose filter cake with a volume average particle diameter of 75 microns was obtained. After drying off 30 wt% of the water, the stirred filter cake was fed into an extrusion spheronizer (Mini 250 type, manufactured by Shenzhen Xinyite), the diameter of the orifice plate was 0.5mm. Dry the spheronized microcrystalline cellulose pellets in an oven at 60°C for 2 hours, remove large particles with a sieve with a pore size of 500 μm, and then remove small particles through a sieve with a pore size of 400 μm to obtain a volume average particle size of 400 to 500...

Embodiment 2

[0041] With the filter cake of embodiment 1, adopt shearing machine (FA 30 type, prepared by FLUKO) to shear 10 minutes, shear 6 to 8 times, the outlet of shearing equipment will be controlled in the first 2 shearing processes Below 12 mm, the outlet of the last 4 to 6 shearing equipment is controlled below 24 mm. After drying off 30% of the moisture, the sheared microcrystalline cellulose filter cake was fed into an extrusion spheronizer (Mini250 type, manufactured by Shenzhen Xinyite), with a diameter of orifice plate of 0.8 mm. Dry the spheronized microcrystalline cellulose pellets in an oven at 60°C for 2 hours, use a sieve with a pore size of 800 μm to remove large particles, and then pass through a sieve with a pore size of 700 μm to remove small particles to obtain a volume average particle size of 700 to 800 μm Table 1 shows the relevant physical characterization parameters of the microcrystalline cellulose pellet core.

Embodiment 3

[0043] Add water to the stirred filter cake in Example 1 to obtain a dispersion with a solid content of 25 wt%, and grind for 60 minutes with a ball mill (GTM 60, manufactured by Shenzhen Leitong). After drying off 40 wt% of water, the ground microcrystalline cellulose filter cake was fed into an extrusion spheronizer (Mini 250 type, manufactured by Shenzhen Xinyite), the diameter of the orifice plate was 0.3 mm. Dry the spheronized microcrystalline cellulose pellets in an oven at 60°C for 2 hours, use a sieve with a pore size of 300 μm to remove large particles, and then pass through a sieve with a pore size of 200 μm to remove small particles to obtain a volume average particle size of 200 to 300 μm Table 1 shows the relevant physical characterization parameters of the microcrystalline cellulose pellet core.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com