Process method for manufacturing manganese products through high-concentration SO2 smoke leaching manganese ore pulp

A process method, SO2 technology, applied in the direction of manganese sulfate, etc., can solve the problem of easy clogging of nozzle nozzle holes, etc., and achieve the effects of low cost, reduced production cost, and high manganese leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

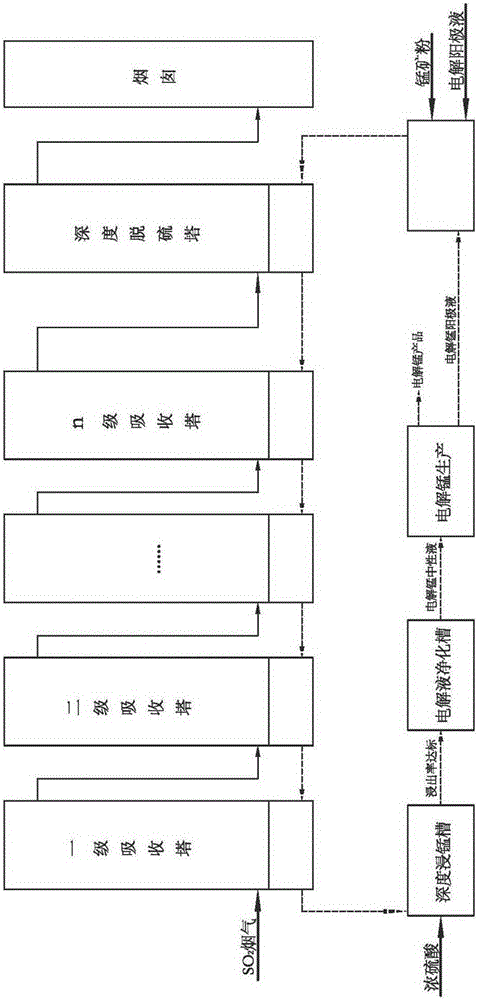

[0032] The manganese oxide ore used in this example comes from South African manganese ore, and the desulfurization slurry is configured with electrolytic manganese anolyte, and the sulfur-containing flue gas is manganese slag calcination flue gas. The composition of flue gas from slag calcination is shown in Table 3, and the process flow is attached image 3 shown.

[0033] Table 1 Manganese ore composition analysis

[0034]

[0035] Table 2 Composition and parameters of electrolytic manganese anolyte

[0036]

[0037] Table 3 Manganese slag calcination flue gas composition list

[0038]

[0039] The specific implementation is as follows:

[0040] 1. Grind the manganese ore and pass through a 100-mesh sieve to obtain the raw material ore powder for later use;

[0041] 2. Manganese ore powder and electrolytic manganese anolyte are mixed by metering according to the liquid-solid weight ratio of 8:1 to make manganese ore slurry, and fully stirred at 70°C to make it ...

Embodiment example 2

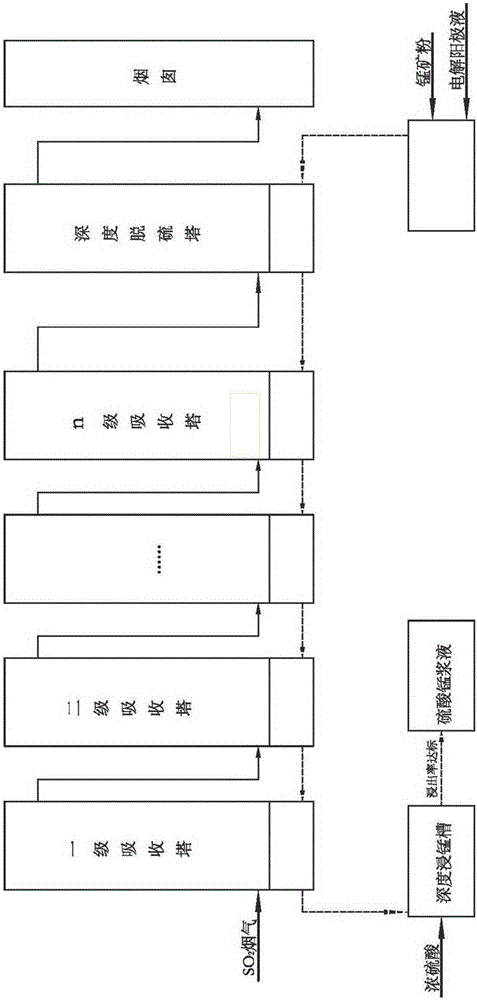

[0051] The manganese oxide ore used in this example comes from South African manganese ore. Desulfurization pulp is prepared with water for desulfurization. The flue gas is simulated flue gas in the laboratory. The composition analysis of manganese ore is shown in Table 5. The composition of the simulated flue gas is shown in Table 6. figure 1 shown.

[0052] Table 5 Manganese ore composition analysis

[0053]

[0054] Table 6 Manganese slag calcination flue gas composition table

[0055]

[0056] The specific implementation is as follows:

[0057] 1. Grind the manganese ore and pass through a 100-mesh sieve to obtain the raw material ore powder for later use;

[0058] 2. Manganese ore powder and water are mixed by metering according to the liquid-solid ratio of 4:1 to make manganese ore slurry, and fully stirred at about 70°C to make it reach a uniform state for later use;

[0059] 3. The desulfurization system is composed of a spray tower designed with five-stage to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com