Method for enhancing fire resistance and thermal stability of PVC through oxidized graphene

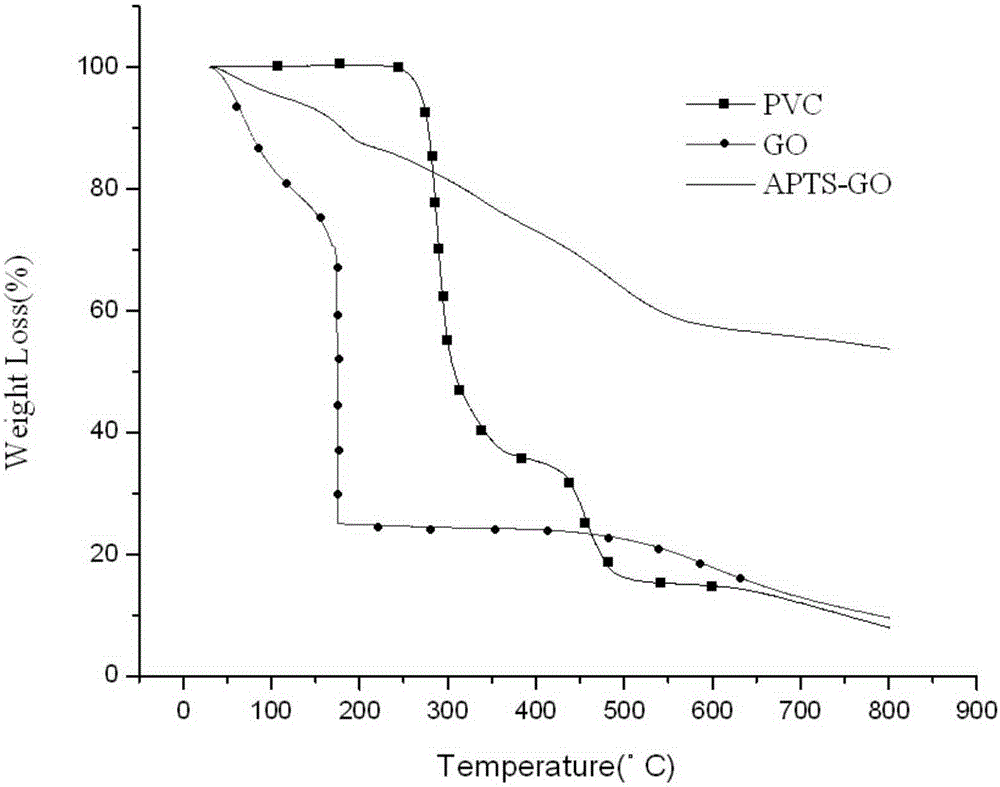

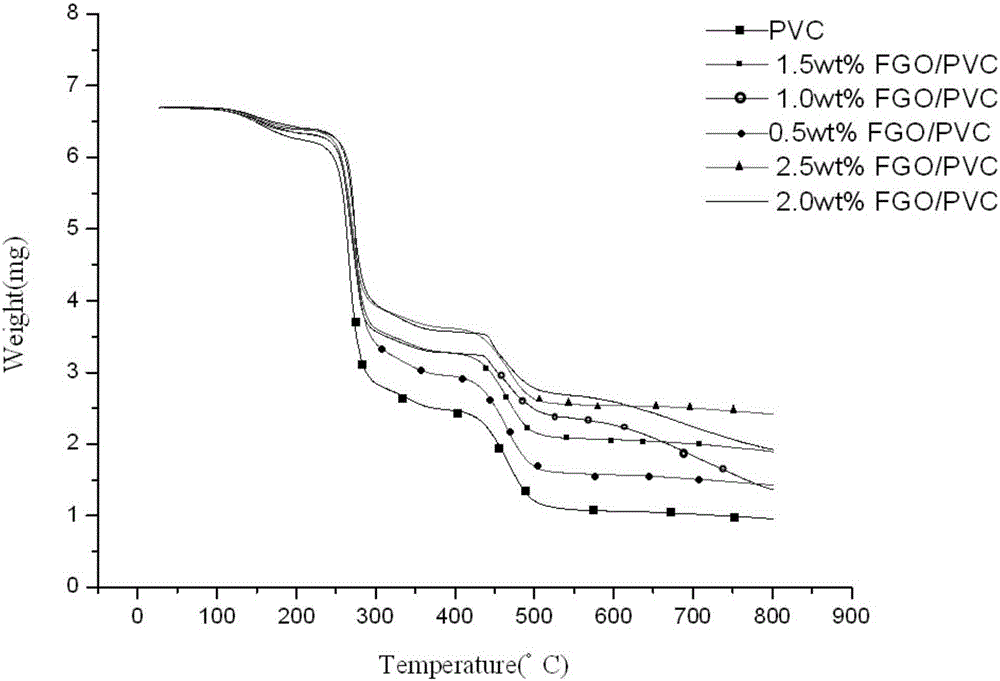

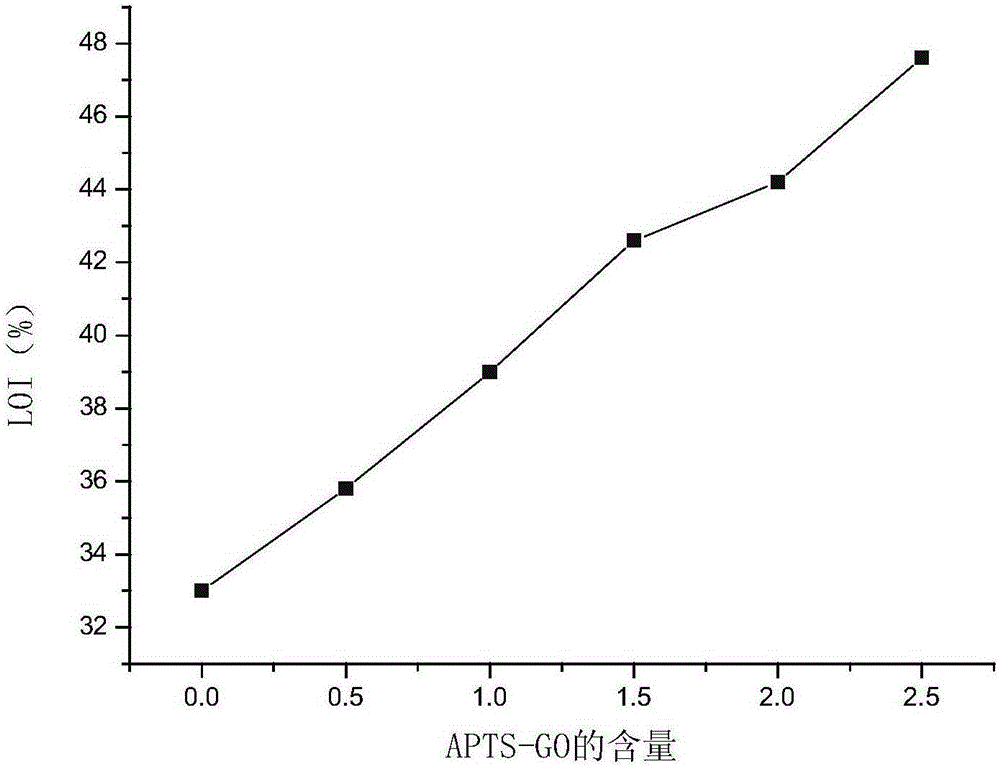

A technology of thermal stability and graphene, applied in the field of new materials, can solve the problems of poor thermal stability and reduced fire resistance of PVC materials, and achieve the effects of enhancing thermal stability, enhancing dispersibility, and enhancing fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Graphene oxide is dispersed in the solvent DMF

[0041] Weigh graphene oxide, the mass (mg) of graphene oxide and the volume (mL) ratio of DMF are 10:30, 20mg graphene oxide that weighs is added in the DMF of 60mL, ultrasonic power 70W, frequency 40KHz, time is 60 minutes, obtains the yellow-brown solution A;

[0042] 2) Modification of graphene oxide

[0043] 2.1) Measure modifying agent APTS, the ratio of the volume (mL) of described modifying agent APTS (3-aminotriethoxypropyl silane) and the quality (mg) of graphene oxide used in step 1) is 0.5:1; Add the weighed 10mL modifier APTS into the tan solution A obtained in step 1) to obtain the mixed solution B;

[0044]2.2) Weigh the dehydrating agent, the mass ratio of the dehydrating agent dicyclohexylcarbodiimide to the graphene oxide used in the step 1) is 50:1; add 1g of the dehydrating agent to the solution B obtained in the step 2.1) , to obtain a gradually darker yellow-brown liquid, which is the mixed liqu...

Embodiment 2

[0060] 1) Graphene oxide is dispersed in the solvent DMF

[0061] Graphene oxide is taken, the ratio of the mass (mg) of the graphene oxide to the volume (mL) of DMF is 20:40, the weighed 40mg graphene oxide is added in the DMF of 80mL, ultrasonic power 70W, The frequency is 40KHz, and the time is 70 minutes to obtain a yellow-brown solution A;

[0062] 2) Modification of graphene oxide

[0063] 2.1) Measure modifying agent APTS, the ratio of the volume of described modifying agent APTS and the graphene oxide mass used in step 1) is 1:1; 20mL modifying agent APTS that weighs is added to step 1 ) in the yellow-brown solution A obtained, to obtain the mixed solution B;

[0064] 2.2) Weigh the dehydrating agent, the mass ratio of the dehydrating agent dicyclohexylcarbodiimide to the graphene oxide used in step 1) is 70:1; 2.8g dehydrating agent is added to the solution B obtained in step 2.1) In the process, a yellowish-brown liquid that gradually becomes darker is obtained, w...

Embodiment 3

[0079] 1) Graphene oxide is dispersed in the solvent DMF

[0080] Take graphene oxide, the ratio of the quality (mg) of described graphene oxide and the volume (mL) of DMF is 30:50, the 60mg graphene oxide that weighs is added in the DMF of 100mL, ultrasonic power 70W, The frequency is 40KHz, and the time is 90 minutes to obtain a yellow-brown solution A;

[0081] 2) Modification of graphene oxide

[0082] 2.1) Measure modifier APTS, the ratio of the volume of the modifier APTS to the graphene oxide used in step 1) is 1:1.5; 90mL modifier APTS weighed is added to step 1 ) in the yellow-brown solution A obtained, to obtain the mixed solution B;

[0083] 2.2) Weigh the dehydrating agent, the mass ratio of the dehydrating agent dicyclohexylcarbodiimide to the graphene oxide used in step 1) is 100:1; add 6g of dehydrating agent to the solution B obtained in step 2.1) , to obtain a gradually darker yellow-brown liquid, which is the mixed liquid C;

[0084] 2.3) Ultrasound the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com