Rubber-metal hot vulcanization type adhesion agent for fast adhesion of vulcanized rubber

A vulcanized rubber, metal heat technology, applied in the direction of halogen rubber derivative adhesives, adhesives, adhesive types, etc., to achieve the effect of rapid bonding process and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

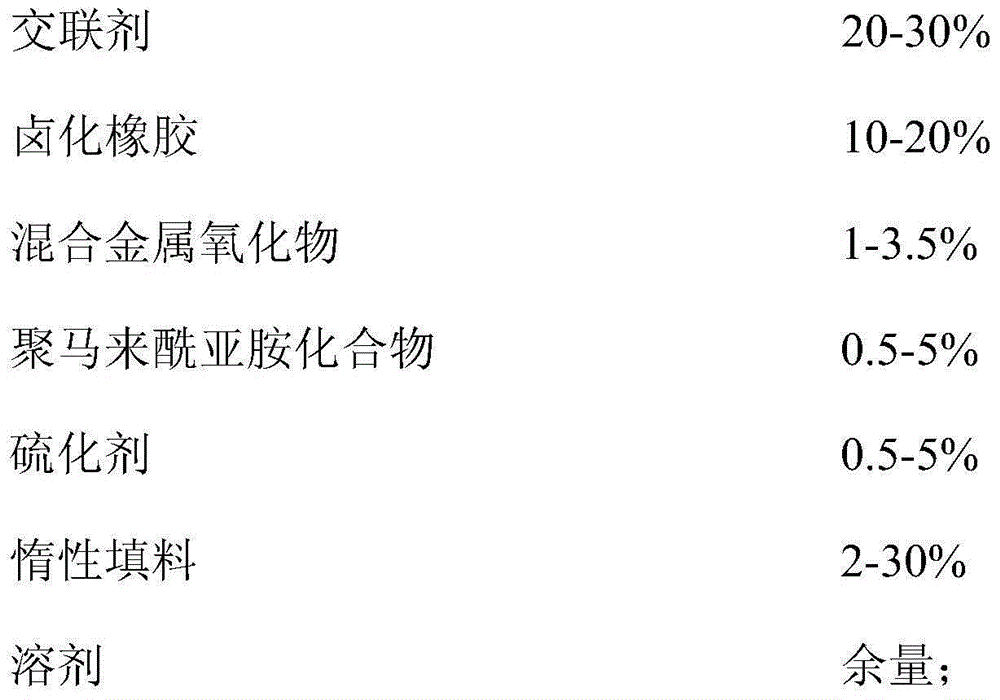

[0046] A rubber-metal thermal vulcanization adhesive for quick bonding of vulcanized rubber, obtained by mixing and preparing the following raw materials according to the ratio:

[0047]

[0048] The crosslinking agent of the present invention is made up of epoxy acrylate, trimethylolpropane trimethacrylate and sodium bisulfite blocked toluene diisocyanate, epoxy acrylate, trimethylolpropane trimethacrylate and The mass ratio of sodium bisulfite blocked toluene diisocyanate is 1:6:10;

[0049] The metal oxide of the present invention is a mixture of zinc oxide, molybdenum oxide and cobalt oxide, and the metal oxide is composed of zinc oxide, molybdenum oxide and cobalt oxide, and the mass ratio of zinc oxide, molybdenum oxide and cobalt oxide is 100:1:2.

[0050] The performance test results of the resulting product are listed in Table 1.

Embodiment 2

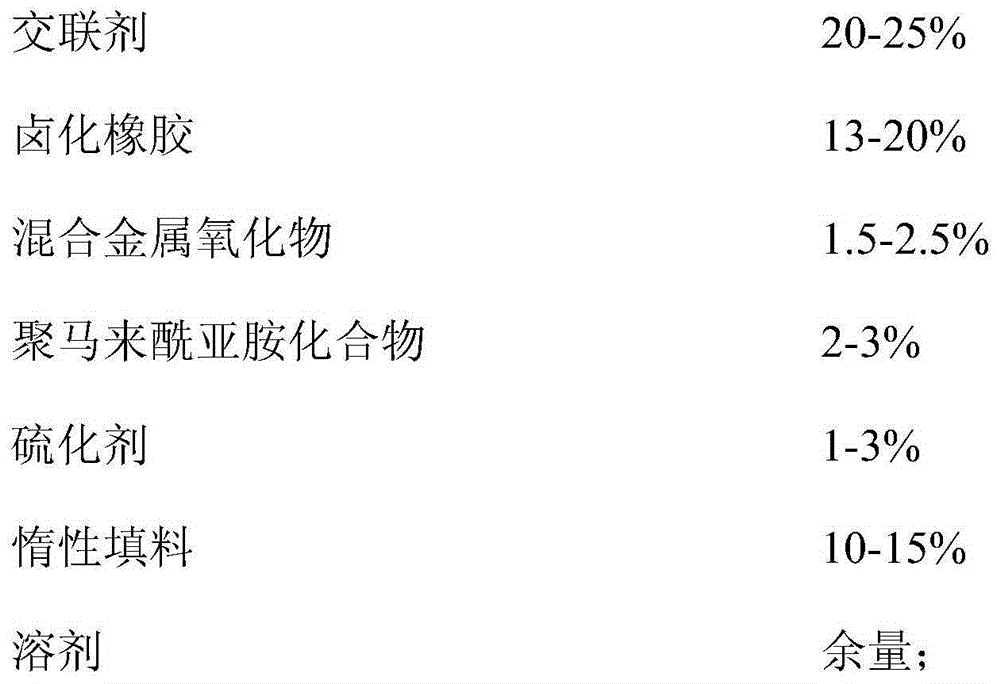

[0052] A rubber-metal thermal vulcanization adhesive for quick bonding of vulcanized rubber, obtained by mixing and preparing the following raw materials according to the ratio:

[0053]

[0054]

[0055] The crosslinking agent of the present invention is made up of epoxy acrylate, trimethylolpropane trimethacrylate and sodium bisulfite blocked toluene diisocyanate, epoxy acrylate, trimethylolpropane trimethacrylate and The mass ratio of sodium bisulfite blocked toluene diisocyanate is 2.5:3.5:13;

[0056] The metal oxide of the present invention is a mixture of zinc oxide, molybdenum oxide and cobalt oxide, and the metal oxide is composed of zinc oxide, molybdenum oxide and cobalt oxide, and the mass ratio of zinc oxide, molybdenum oxide and cobalt oxide is 100:1:5;

[0057] The performance test results of the resulting product are listed in Table 1.

Embodiment 3

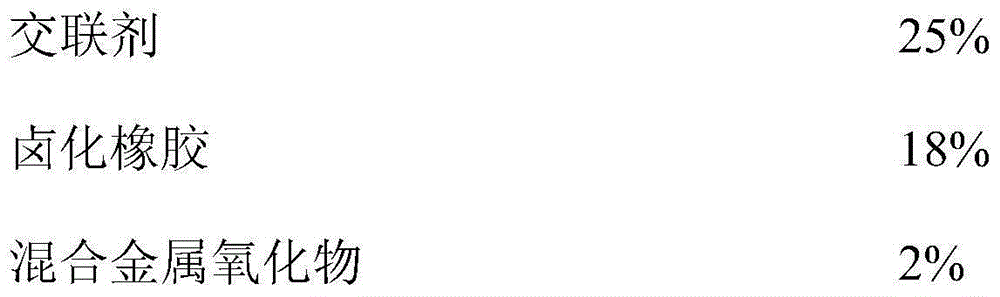

[0059] A rubber-metal thermal vulcanization adhesive for quick bonding of vulcanized rubber, obtained by mixing and preparing the following raw materials according to the ratio:

[0060]

[0061] Wherein, the crosslinking agent is composed of epoxy acrylate, trimethylolpropane trimethacrylate and sodium bisulfite blocked toluene diisocyanate, epoxy acrylate, trimethylolpropane trimethacrylate and The mass ratio of sodium bisulfite blocked toluene diisocyanate is 1.5:4:12;

[0062] The metal oxide is a mixture of zinc oxide, molybdenum oxide and cobalt oxide, and the metal oxide is composed of zinc oxide, molybdenum oxide and cobalt oxide, and the mass ratio of zinc oxide, molybdenum oxide and cobalt oxide is 100: 1:2;

[0063] The performance test results of the resulting product are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com