Sealing compound for batteries and preparation method of ealing compound

A sealing glue, battery technology, applied in the direction of adhesive, epoxy glue, adhesive type, etc., can solve the problems of poor adhesion, easy aging cost, etc., to achieve easy coating, good adhesion, long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A method for preparing a battery sealant of the present invention comprises the following steps: 1) heating 45 parts by weight of asphalt at 150°C for 2 hours, adding 10 parts by weight of modified epoxy resin, 10 parts by weight of nonyl Phenol polyoxyethylene ether and 1 weight part of fumed silica were stirred evenly to obtain a crude product; 2) when the temperature of the crude product obtained in step 1) was cooled to 80°C, 10 weight parts of gasoline and 10 Aromatic oil in parts by weight is uniformly stirred, filtered and packaged to obtain the product.

Embodiment 2

[0014] A method for preparing a battery sealant of the present invention comprises the following steps: 1) heating 50 parts by weight of asphalt at 180°C for 3.5 hours, adding 15 parts by weight of modified epoxy resin, 15 parts by weight of nonyl phenol polyoxyethylene ether and 3 parts by weight of fumed silica, and stir evenly to obtain a crude product; 2) when the temperature of the crude product obtained in step 1) is cooled to 100°C, add 15 parts by weight of gasoline and 15 parts by weight of aromatic oil, stirred evenly, filtered and packaged to obtain the product.

Embodiment 3

[0016] A method for preparing a battery sealant of the present invention comprises the following steps: 1) heating 55 parts by weight of asphalt at 200°C for 5 hours, adding 20 parts by weight of modified epoxy resin, 20 parts by weight of nonyl Phenol polyoxyethylene ether and 5 parts by weight of fumed silica were stirred evenly to obtain a crude product; 2) when the temperature of the crude product obtained in step 1) was cooled to 120°C, 20 parts by weight of gasoline and 20 Aromatic oil in parts by weight is uniformly stirred, filtered and packaged to obtain the product.

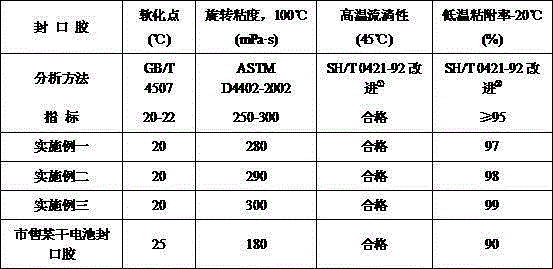

[0017] The performance of the three battery sealants obtained in Examples 1 to 3 and a commercially available battery sealant were tested with reference to the relevant test methods of the battery sealant SH / T0421-92 petrochemical industry standard. The test results are shown in the table 1; as can be seen from Table 1, battery sealant of the present invention has all reached the requirement of index in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com