Circular gas heat carrier coal pyrolysis system and pyrolysis method thereof

A gas heat carrier and coal pyrolysis technology, applied in the field of coal pyrolysis, can solve the problems of low energy conversion efficiency, large energy loss, and poor quality, and achieve the goals of avoiding transmission and heat preservation, less water vapor content, and improving conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

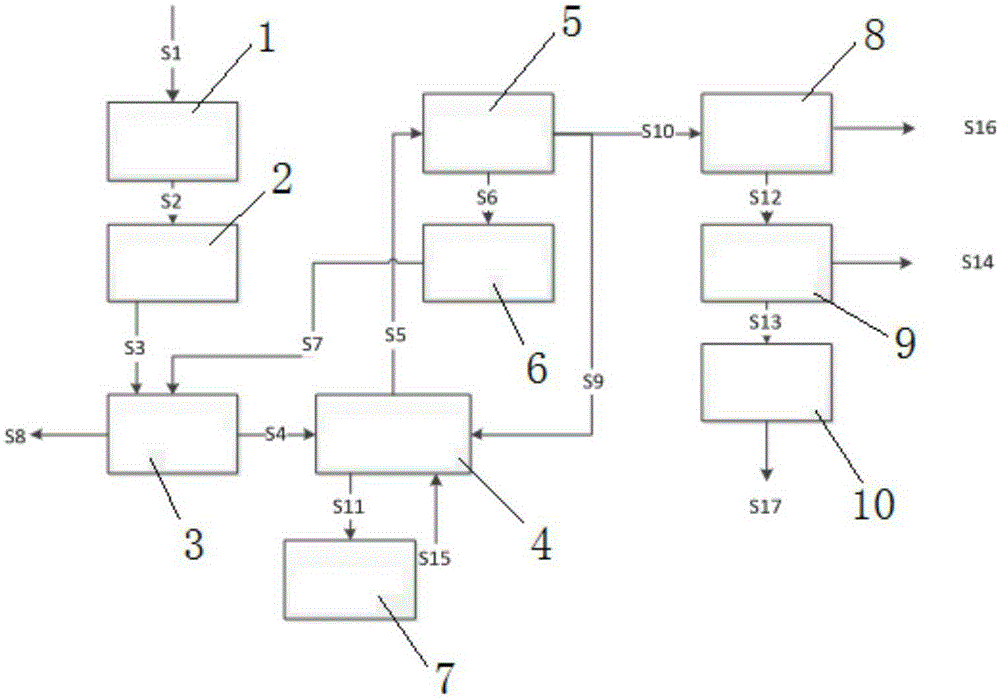

[0018] A circulating gas heat carrier coal pyrolysis system, such as figure 1 As shown, it includes dry coal grinding device, pressurization device, heat exchanger, pyrolysis / burner, gas-solid separation device, tar recovery device, cryogenic separation device and conversion / purification / synthesis device connected in sequence; gas-solid separation The device is also connected with the heat exchanger through the semi-coke storage tank; the tar recovery device is also connected with the pyrolysis / burner; the pyrolysis / burner is also connected with the waste heat boiler.

Embodiment 2

[0020] A pyrolysis method of a circulating gas heat carrier coal pyrolysis system, such as figure 1 As shown, the coal S1 passes through the drying coal grinding device 1, pre-dried, crushed and ground to a certain particle size, enters the pressurizing device 2, increases the environmental pressure of the coal, and enters the heat exchanger 3 to exchange heat with the high-temperature semi-coke S7 , the semi-coke is output as product S8 after the temperature of the semi-coke is lowered, and the coal particles are heated and transported to the pyrolysis / burner 4, where they exchange heat with high-temperature flue gas and undergo pyrolysis to produce a mixture S5, which enters the gas-solid separation device 5 for separation The solid high-temperature semi-coke S6 is transported to the semi-coke storage tank 6, and the remaining gas after gas-solid separation mainly includes methane, carbon monoxide, hydrogen, gaseous tar components, water vapor, etc., and a part of it is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com