Cerium-doped zinc oxide nanofiber qcm humidity sensor and preparation method thereof

A zinc oxide nanometer, humidity sensor technology, applied in instruments, scientific instruments, material weighing, etc., can solve the problems of long response time of humidity sensors, affecting the practical application of sensors, etc., to shorten sampling time, strong practicability, preparation simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of zinc oxide nanofiber QCM humidity sensor, comprising the following steps:

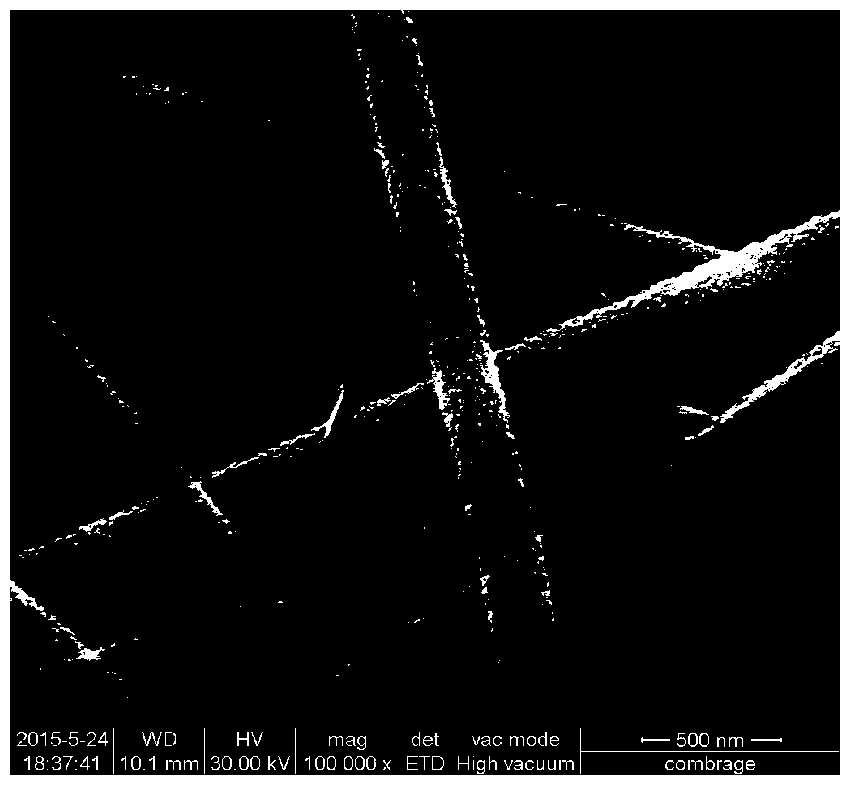

[0032] (1) Preparation of zinc oxide nanofiber sensitive layer: 1.2 grams of zinc acetate, 0.08 grams of cerium nitrate, 0.45 grams of deionized water and 2.0 grams of absolute ethanol were mixed and then magnetically stirred, 1.2 grams of polyvinylpyrrolidone with a molecular weight of 1.3 million and 8.5 grams After mixing absolute ethanol, heat and stir in a water bath at 60°C for 2 hours. After the solution is evenly stirred, slowly pour the cooled PVP solution into the zinc acetate solution, and stir magnetically for 1 hour to prepare a precursor spinning solution doped with cerium zinc oxide. The prepared cerium-doped zinc oxide nanofibers were prepared by spinning, the spinning temperature was 20°C, the humidity was 60%, the spinning distance was 13.5 cm, and the spinning voltage was 25 kV; the prepared cerium-doped zinc oxide nanofibers were placed in a muffle Dur...

Embodiment 2

[0036] A preparation method of a zinc oxide nanofiber quartz crystal microbalance humidity sensor, comprising the following steps:

[0037] (1) Preparation of the zinc oxide nanofiber sensitive layer: first dissolve 1 gram of polyethylene oxide PEO (relative molecular mass 5,000,000) in deionized water, place it in the Erlenmeyer flask A, and stir it with a magnetic stirrer for 4 hours at room temperature. To obtain solution A, add 1.2 grams of zinc acetate and 0.08 grams of cerium nitrate into a conical flask B equipped with 2 grams of absolute ethanol and 0.45 grams of deionized water, and stir for 2 hours under a magnetic stirrer to obtain inorganic salt solution B, mix The prepared polymer solution A and inorganic salt solution B are fully stirred with a magnetic stirrer for 2 hours to obtain a precursor spinning solution of zinc oxide; the positive pole of the high voltage power supply of the electrospinning device is connected to the needle tip of the syringe, and the neg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com