Nickel, cobalt and aluminum hydroxide and preparation method thereof and cathode material for lithium ion cell

A hydroxide, nickel-cobalt-aluminum technology, used in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor thermal stability, poor overcharge resistance, and high irreversible capacity at the first discharge. High solid density, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

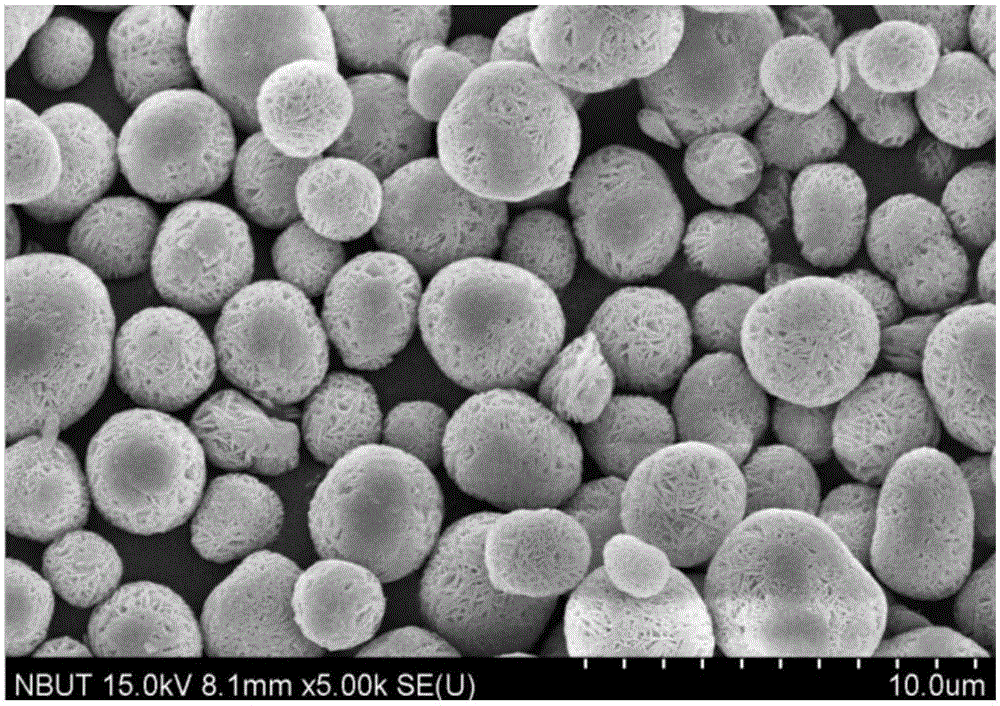

[0039] The invention provides a method for preparing nickel-cobalt-aluminum hydroxide, comprising:

[0040] Mixing the nickel salt solution and the cobalt salt solution to obtain the first mixed solution;

[0041] mixing the aluminum salt solution with a complexing agent to obtain a second solution, the complexing agent comprising ammonia water, disodium edetate, sulfosalicylic acid or glycine;

[0042] Under the action of a precipitating agent, the first mixed solution and the second mixed solution are subjected to coprecipitation reaction to obtain nickel cobalt aluminum hydroxide;

[0043] The temperature of the co-precipitation reaction is 40°C to 65°C,

[0044] The pH value of the co-precipitation reaction is 10.5-12;

[0045] The nickel-cobalt-aluminum hydroxide is a compound shown in formula I:

[0046] Ni 1-x-y co x Al y (OH) 2+y Formula I;

[0047] In Formula I, 0.1≤x≤0.2, 0.03≤y≤0.10.

[0048] The invention mixes the nickel salt solution and the cobalt salt ...

Embodiment 1

[0070] Dissolving nickel sulfate and cobalt sulfate in water is made into the first mixed solution whose metal ion concentration is 1.5mol / L, and the molar ratio of nickel and cobalt in the first mixed solution is 8:1;

[0071] Aluminum sulfate solution and sulfosalicylic acid are made into the second mixed solution that aluminum ion concentration is 0.4mol / L by the molar ratio of 1:0.5;

[0072] The first mixed solution, the second mixed solution, 9.5 mol / L ammonia water and 6 mol / L sodium hydroxide solution are added to the reaction vessel in parallel flow through a metering pump, at 55 ° C and a stirring speed of 220 rpm Carry out continuous co-precipitation reaction under the condition that the pumping speed ratio of the first mixed solution and the second mixed solution is 4.8:1; control the pumping speed of ammonia water and sodium hydroxide solution so that the ammonia value in the coprecipitation process is 14.5 , the pH value is 11.6;

[0073] The obtained co-precipi...

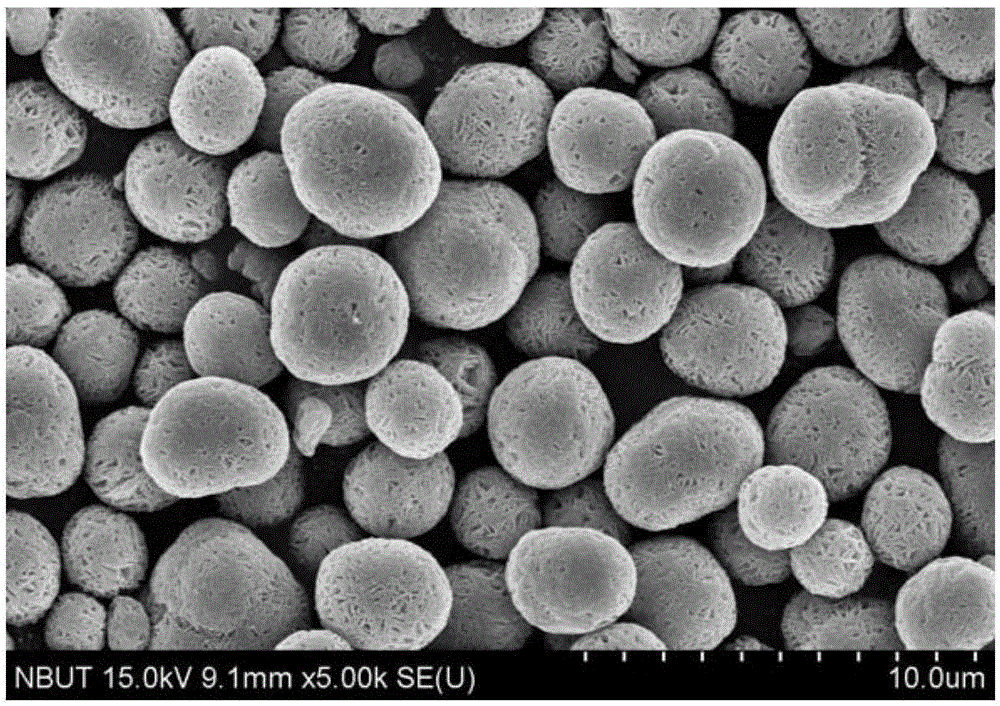

Embodiment 2

[0078] Dissolving nickel sulfate and cobalt sulfate in water is made into the first mixed solution whose metal ion concentration is 1.5mol / L, and the mol ratio of nickel and cobalt in the first mixed solution is 8.45:1.55;

[0079] Aluminum sulfate solution and sulfosalicylic acid are made into the second mixed solution that aluminum ion concentration is 0.4mol / L by the molar ratio of 1:3;

[0080] The first mixed solution, the second mixed solution, 9.5 mol / L ammonia water and 6 mol / L sodium hydroxide solution are added to the reaction vessel in parallel flow through a metering pump, at 45 ° C and a stirring speed of 270 rpm Carry out continuous co-precipitation reaction under the condition that the pumping speed ratio of the first mixed solution and the second mixed solution is 7.3:1; control the pumping speed of ammonia water and sodium hydroxide solution so that the ammonia value in the coprecipitation process is 16.5 , the pH value is 11.3;

[0081] The obtained co-preci...

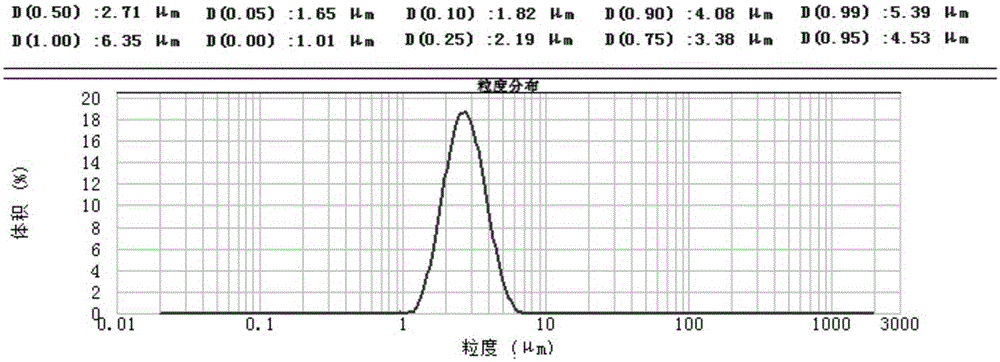

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com