Method for preparing nano aluminum nitride powder through sol-gel foaming

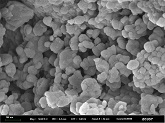

A technology of nano-aluminum nitride and foaming method, which is applied in the direction of chemical instruments and methods, nitrogen compounds, nanotechnology, etc., and can solve the problems of difficult large-scale industrial production, complex production process of nano-aluminum nitride powder, no production process, etc. problems, to achieve the effect of novel preparation method, low cost and good spherical particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The method for preparing nano aluminum nitride powder by sol-gel foaming comprises the following steps.

[0033] (1) Weigh aluminum nitrate nonahydrate and sucrose according to the molar ratio of element molar ratio Al:C=1:10, weigh according to the mass ratio of aluminum nitrate nonahydrate and ammonium chloride 1:0.16, and weigh the raw materials After adding a certain amount of water to dissolve, dry at 45°C to a light yellow transparent gel, then foam at 300°C, grind the fluffy and porous substance to obtain a reddish-brown precursor powder, which is Formed in the foaming fluffy process, it is composed of amorphous nano-scale alumina and carbon, and the alumina is evenly wrapped by carbon.

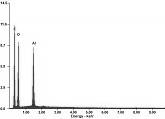

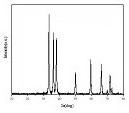

[0034] (2) The nano-scale precursor powder is pretreated, specifically roasting at 600°C for 100 minutes, then adding a small amount of carbon powder for grinding, and then nitriding with nitrogen in a tube furnace. The heating process is: at 5°C The heating rate was raised fro...

Embodiment 2

[0038] (1) Weigh aluminum nitrate nonahydrate and glucose according to the molar ratio of element molar ratio Al:C=1:10, weigh according to the mass ratio of aluminum nitrate nonahydrate and ammonium acetate 1:0.2, add the weighed raw materials After a certain amount of water is dissolved, it is dried at 45°C to light yellow transparent gel, and then foamed at 350°C, and the fluffy and porous substance is ground to obtain a reddish-brown precursor powder, which is a hair Formed during the fluffy process of bubbles, it is composed of amorphous nano-scale alumina and carbon, and alumina is evenly wrapped by carbon.

[0039] (2) The nanoscale precursor powder is pretreated and then nitrided at high temperature. The heating process is as follows: the heating rate is 5° C. / min from room temperature to 1400° C., and then kept at this temperature for 2 hours.

[0040] (3) Heat the carbon-containing nano-aluminum nitride powder in the air at a heating rate of 7 °C / min to 580 °C, keep ...

Embodiment 3

[0043] (1) Weigh aluminum nitrate nonahydrate and glucose according to the molar ratio of element molar ratio C:Al=1:9, weigh according to the mass ratio of aluminum nitrate nonahydrate and ammonium oxalate 1:0.18, add the weighed raw materials After a certain amount of water is dissolved, it is dried at 45°C to a light yellow transparent gel, and then foamed at 280°C, and the fluffy and porous substance is ground to obtain a reddish-brown precursor powder. Formed in the process of foaming and fluffy, it is composed of amorphous nano-scale alumina and carbon, and the alumina is uniformly wrapped by carbon.

[0044] (2) The nanoscale precursor powder is pretreated and then nitrided at high temperature. The heating process is as follows: the heating rate is 5° C. / min from room temperature to 1400° C., and then kept at this temperature for 2.5 hours.

[0045] (3) Heat the carbon-containing nano-aluminum nitride powder in air at a heating rate of 7 °C / min to 580 °C, keep it warm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com