Low-grade gold ore pile soaking technology based on high-pressure roller smashing

A low-grade, high-pressure roller technology, applied in the field of metallurgy, can solve problems such as increased crushing costs, greater difficulty in dissociation, and restrictions on the development of gold mining enterprises, so as to reduce the consumption of leaching agents, speed up the reaction rate, and shorten the heap leaching cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

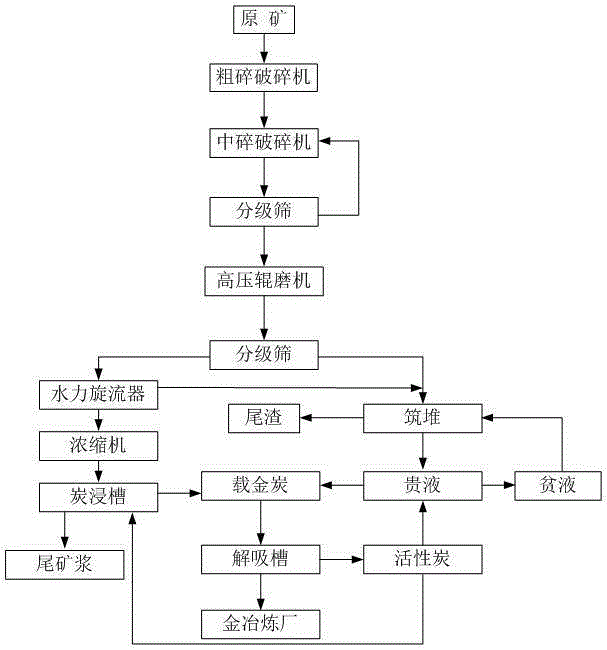

Method used

Image

Examples

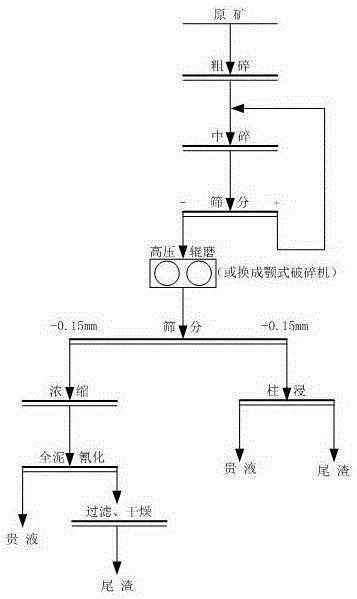

Embodiment 1

[0025] A very low-grade oxidized gold ore, the gold content in the ore is 0.34g / t, the metal minerals are mainly limonite and pyrite; most of the gangue minerals are quartz, and the ore has a high mud content. The ore sample adopts two types of jaw crushers, PEX-150×250 and XPC-60×100, and a closed-circuit crushing process consisting of a 20mm round hole screen for primary and secondary crushing to ensure that the particle size of the ore is less than 20mm, and then PEF- The 60×100 jaw crusher is used for fully open-circuit fine crushing (the width of the ore discharge port of the jaw crusher is controlled to be 4~7mm). The crushed products of the jaw crusher are screened and classified, and the materials with a particle size of +0.15mm (accounting for 90.01%) are used as column leaching test samples. =650mm, the spray intensity of peristaltic pump is 10L / m 2 h, the concentration of sodium cyanide solution is 0.8g / L, leaching for 20 days in a closed circuit (poor solution is ...

Embodiment 2

[0028] A very low-grade oxidized gold ore, the gold content in the ore is 0.34g / t, the metal minerals are mainly limonite and pyrite; most of the gangue minerals are quartz, and the ore has a high mud content. The ore sample adopts the closed-circuit crushing process consisting of PEX-150×250 and XPC-60×100 jaw crushers and 20mm round hole sieves for primary and secondary crushing to ensure that the ore particle size is less than 20mm, and then CLM- 25-10 high pressure roller mill for full open circuit fine crushing. The diameter of the two rollers of the high-pressure roller mill is 250mm, the width of the two rollers is 100mm, and the pressure on the roller surface is controlled at 3.5N / mm 2 , the distance between the two rollers is 4~7mm, and the roller speed is 0.4m / s. The products crushed by high-pressure rollers are screened and classified, and the +0.15mm particle size material (accounting for 80.66%) is used as a column leaching test sample. The sample is fed into a s...

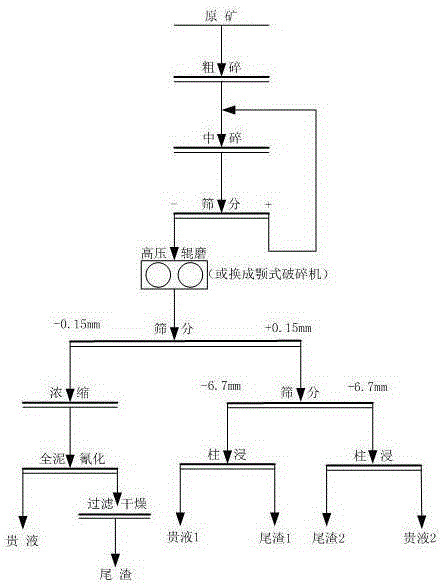

Embodiment 3

[0031] A very low-grade oxidized gold ore, the gold content in the ore is 0.34g / t, the metal minerals are mainly limonite and pyrite; most of the gangue minerals are quartz, and the ore has a high mud content. The ore sample adopts the closed-circuit crushing process consisting of PEX-150×250 and XPC-60×100 jaw crushers and 20mm round hole sieves for primary and secondary crushing to ensure that the ore particle size is less than 20mm, and then CLM- 25-10 high pressure roller mill for full open circuit fine crushing. The diameter of the two rollers of the high-pressure roller mill is 250mm, the width of the two rollers is 100mm, and the pressure on the roller surface is controlled at 5.5N / mm 2, the distance between the two rollers is 4~7mm, and the roller speed is 0.4m / s. The products crushed by high-pressure rollers are screened and classified, and the +0.15mm particle size material (accounting for 78.13%) is used as the column leaching test sample. The sample is fed into a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com