Composite glass wool

A glass wool and glass fiber technology, applied in the field of thermal insulation materials, can solve the problems of lack of suitable materials for thermal insulation, contradicting long-term planning and development, and unfavorable social sustainable development, and achieve the effect of low thermal conductivity and reduced thermal conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

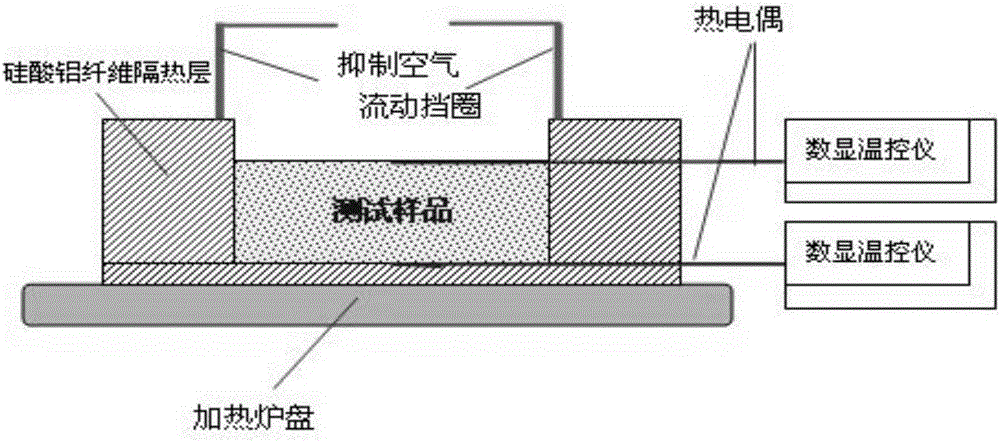

[0096] nano-SiO 2, has the following basic properties: the specific surface area is 200±25m 2 / g; loss on drying is 1% (drying at 100°C for 2h); loss on ignition is 4% (burning at 1000°C for 2h); purity is 99.8%; pH value of suspension is 3.7~4.7 (4% water suspension Turbid liquid); the bulk density is 50g / L; the particle size range is 10nm to 20nm; the average particle size is about 15nm.

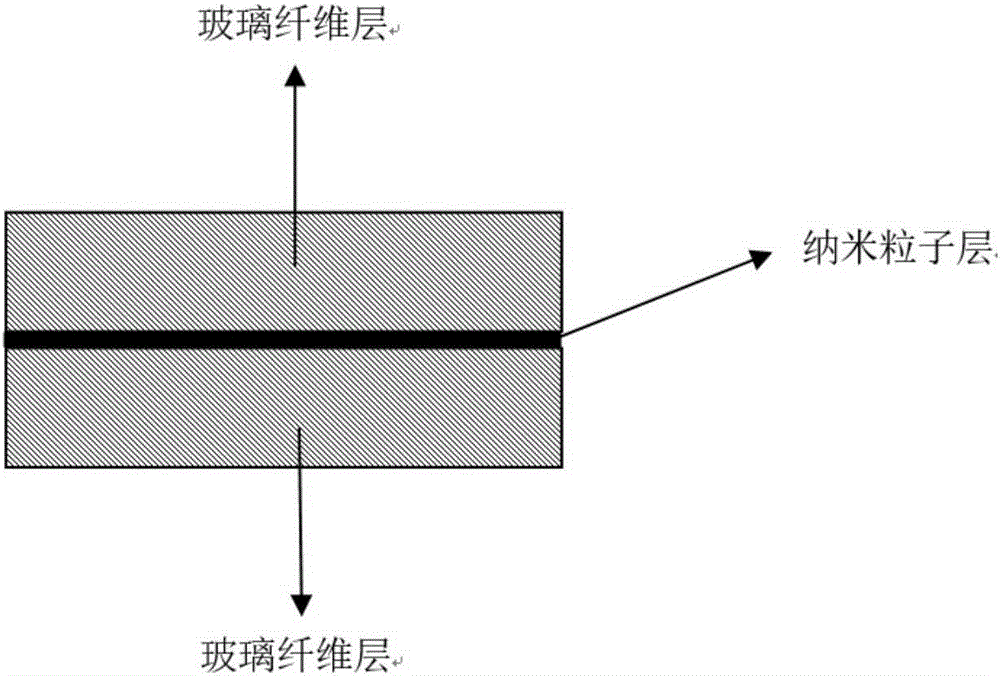

[0097] Spray 4g of acrylic resin binder into 37g of the above-mentioned glass fiber, and then put it into a mold and use a YES-300 pressure testing machine for compression molding. During the pressing process, the pressure was firstly applied slowly by controlling the application rate of the pressure until the sample reached a thickness of 1 cm, and then the pressure delivery was stopped to obtain a glass fiber layer.

[0098] Appropriate amount of nano-SiO 2 The ethanol solution was sprayed onto the above-mentioned glass fiber layer so that the solvent evaporated to form a 120nm thick ...

Embodiment 2

[0103] In addition to adding half the amount of nano-SiO 2 , and nano-SiO 2 The same method as in Example 1 was used to prepare the composite glass wool of the present invention except for the same amount of silicon carbide (with a particle size ranging from 2 μm to 4 μm; an average particle size of about 3 μm).

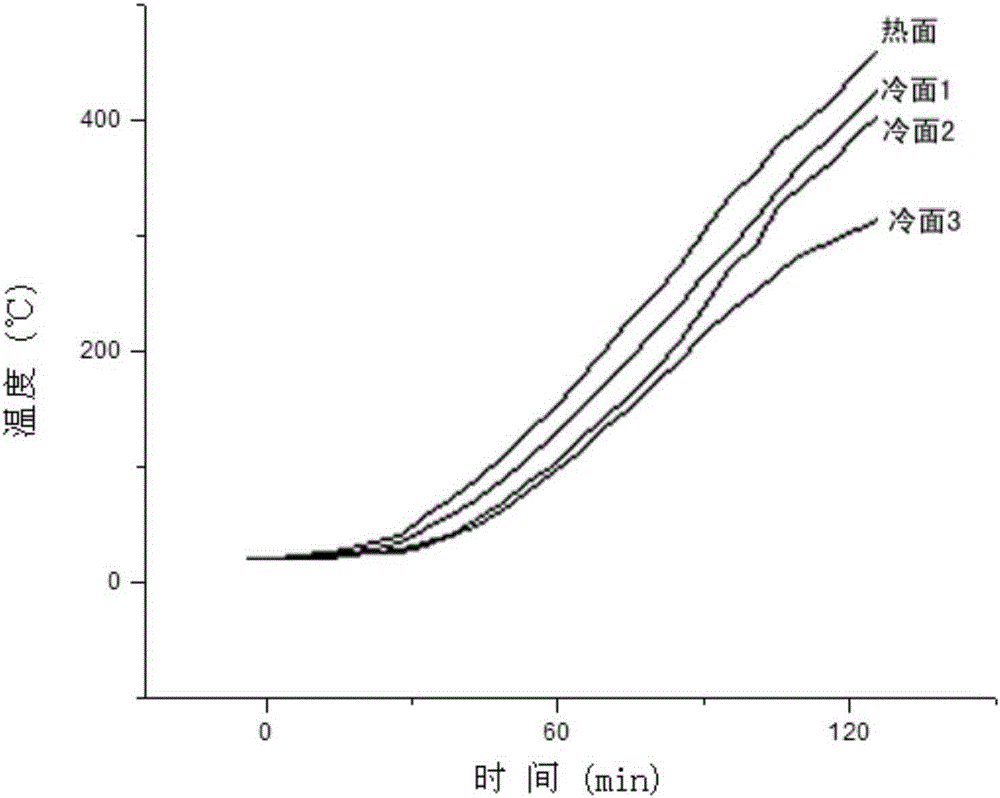

[0104] The results of the back temperature test were as follows: image 3 shown. It can be seen that the maximum temperature difference between the hot surface and the cold surface 3 of the glass wool is 119 degrees, and the gap tends to widen.

Embodiment 3

[0106] In addition to adding half the amount of nano-SiO 2 , and nano-SiO 2 Equal amount of silicon carbide (particle size range is 2μm ~ 4μm; average particle size is about 3μm), nano-SiO 2 1 / 10 of the amount of nano-Al 2 o 3 (The average particle diameter is about 30nm~about 50nm), adopt the same method as Example 1 to prepare the composite glass wool of the present invention.

[0107] The results of the back temperature test show that the thermal insulation effect of the glass wool is better than that of Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com