All-polyester resin for HAA curable coil powder coating and preparation method thereof

A technology of powder coating and polyester resin, applied in the field of polyester resin, can solve the problems of decreased impact resistance, insufficient weather resistance and poor bending performance of the coating, and achieve the effect of good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

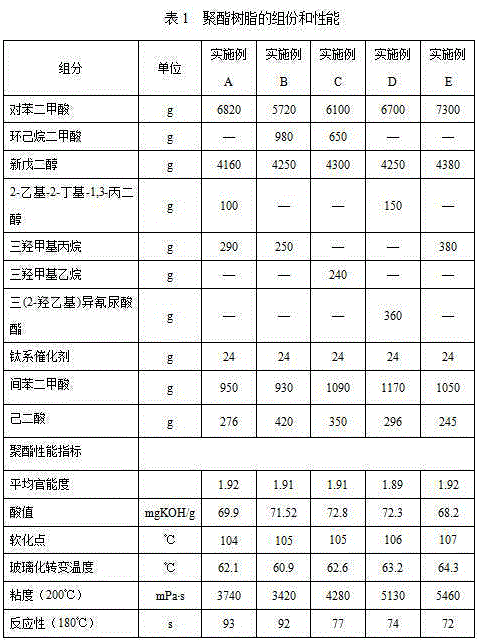

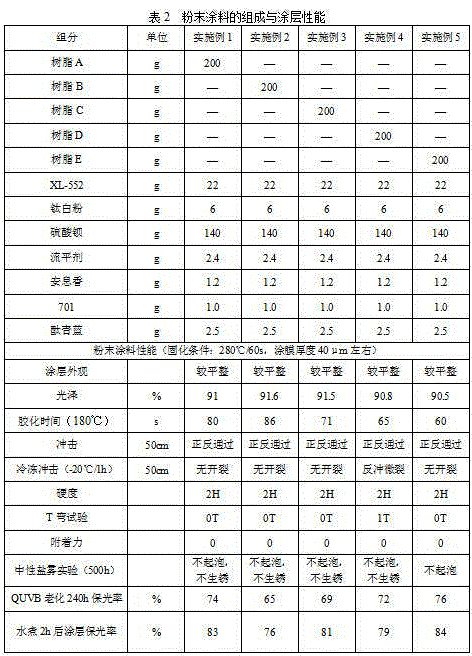

[0017] The present invention is described below in conjunction with embodiment, and table 1 is the embodiment of polyester resin. In the reactor, add neopentyl glycol, trimethylolpropane, trimethylolethane, tris (2-hydroxyethyl) isocyanurate in the ratio listed in Table 1, and heat up to the Melt; then add terephthalic acid and butyl tin oxide, and continue to heat up the reaction with nitrogen gas. Esterified water begins to form and distill at about 185°C, then gradually heat up to 240°C, and react for 10 to 13 hours to reach 95% esterified water After discharge, the acid value reaches 20-24 mgKOH / g, add acidolysis agent isophthalic acid or adipic acid, react for 2.5-4 hours, the acid value reaches 80-85 mgKOH / g, vacuum polycondensation takes about 2.5-4 hours, the acid value reaches 68~74mgKOH / g, the reaction can be stopped.

[0018] Average functionality of polyester resin: 1.85-1.95; acid value: 68-74mgKOH / g; glass transition temperature: 60-65°C; softening point: 102-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com