Novel antibacterial deodorant textile material and preparation method thereof

A technology for textile materials and deodorization, applied in the field of textile materials, can solve the problems of difficult long-term maintenance and loss of drug efficacy of fabrics, and achieve the effects of good deodorization and sterilization performance, simple preparation method, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

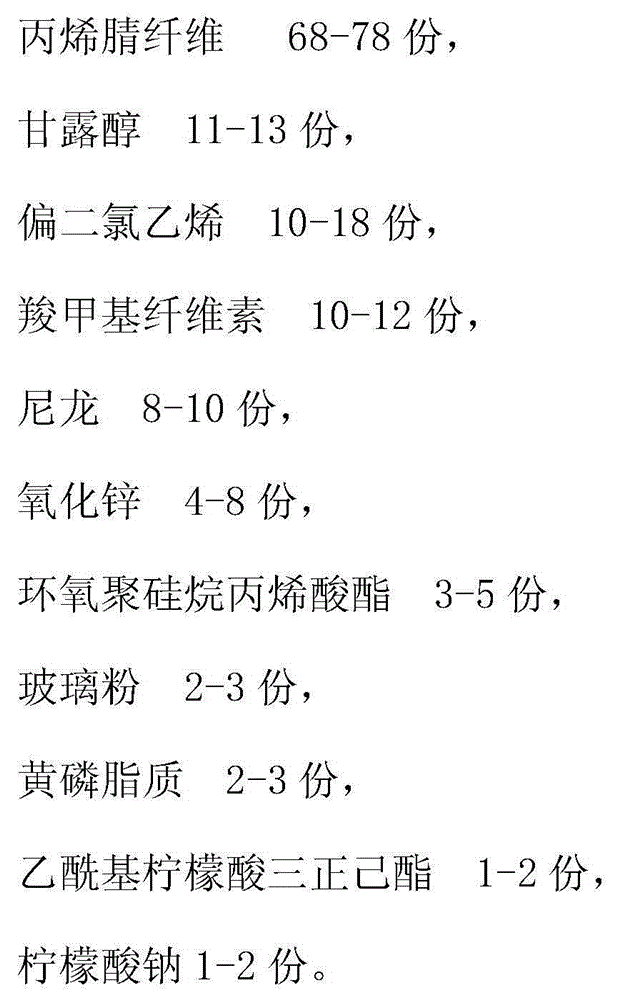

[0031] (1) Take by weighing 68kg of acrylonitrile fiber, 11kg of mannitol, 10kg of vinylidene chloride, 3kg of epoxy polysilane acrylate, 2kg of yellow phospholipid and 1kg of acetyl tri-n-hexyl citrate, and stir evenly at 60°C;

[0032] (2) Add ground glass powder 2kg, zinc oxide 4kg and sodium citrate 1kg, add in the twin-screw extruder, add carboxymethyl cellulose 10kg, 8kg nylon 6 at the side feeding port of the twin-screw extruder, Melt, extrude, dry, and pelletize to obtain antibacterial and deodorant textile materials.

[0033] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 210°C, the temperature of the third zone is 220°C, and the temperature of the fourth zone is 190°C.

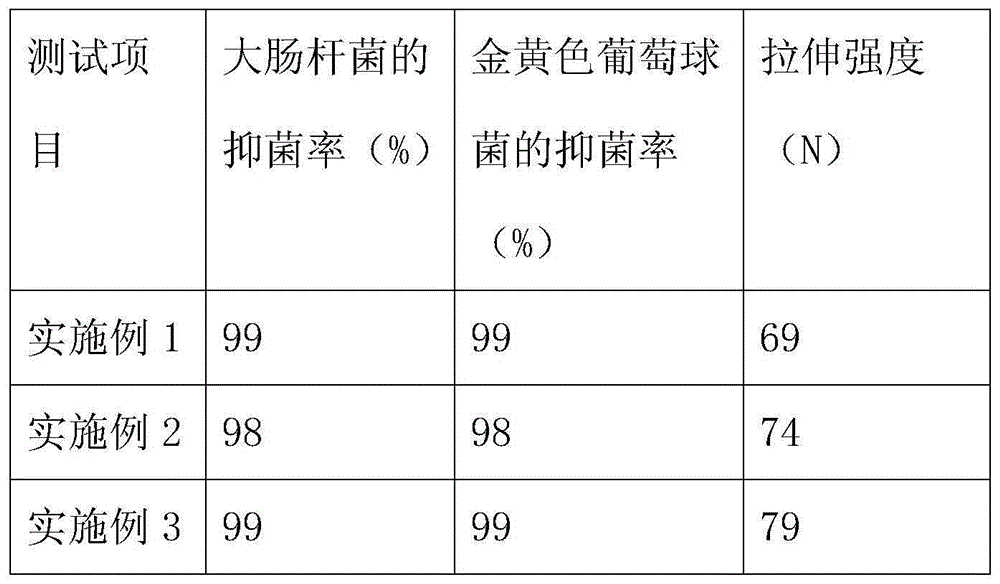

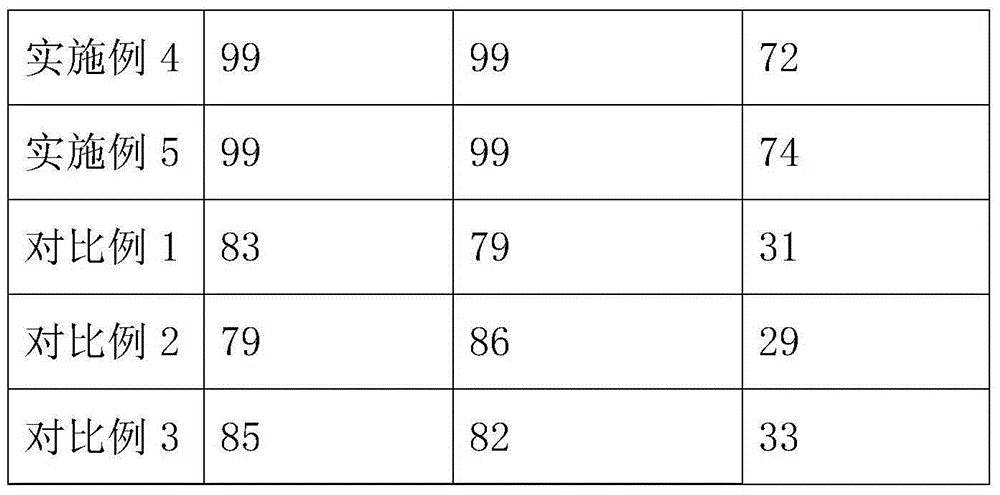

[0034] The performance test results of the prepared antibacterial and deodorant textile materials are shown in Table 1.

Embodiment 2

[0036] (1) Take by weighing 68kg of acrylonitrile fiber, 11kg of mannitol, 10kg of vinylidene chloride, 3kg of epoxy polysilane acrylate, 2kg of yellow phospholipid, 1kg of acetyl tri-n-hexyl citrate and 1kg of trimethyl metasilicate, Stir evenly at 60°C;

[0037] (2) Add 2kg of ground glass powder, 4kg of zinc oxide, 1kg of sodium citrate and 1kg of toner, add in the twin-screw extruder, add carboxymethyl cellulose 10kg, 8kg of nylon 6 is melted, extruded, dried, and pelletized to obtain an antibacterial and deodorant textile material.

[0038] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 180°C, the temperature of the second zone is 210°C, the temperature of the third zone is 220°C, and the temperature of the fourth zone is 190°C.

[0039] The performance test results of the prepared antibacterial and deodorant textile materials are shown in Table 1.

Embodiment 3

[0041] (1) Take by weighing 78kg of acrylonitrile fiber, 13kg of mannitol, 18kg of vinylidene chloride, 5kg of epoxy polysilane acrylate, 3kg of yellow phospholipid, 2kg of acetyl tri-n-hexyl citrate and 1kg of trimethyl metasilicate, Stir evenly at 70°C;

[0042] (2) add ground glass powder 3kg, zinc oxide 8kg, sodium citrate 2kg and toner 1kg, add in the twin-screw extruder, add carboxymethyl cellulose 12kg, 10kg of nylon 6 is melted, extruded, dried, and pelletized to obtain an antibacterial and deodorant textile material.

[0043] The temperature of each section of the twin-screw extruder is as follows: the temperature of the first zone is 200°C, the temperature of the second zone is 220°C, the temperature of the third zone is 230°C, and the temperature of the fourth zone is 200°C.

[0044] The performance test results of the prepared antibacterial and deodorant textile materials are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com