Preparation method for metal nano-particle ordered microstructure

A technology of metal nanoparticles and microstructures, applied in metal processing equipment, metal material coating technology, manufacturing tools, etc., can solve the problems of increased cost, ineffective use of metal films, expensive raw materials, etc., and achieve economical use , high efficiency, simple preparation process and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

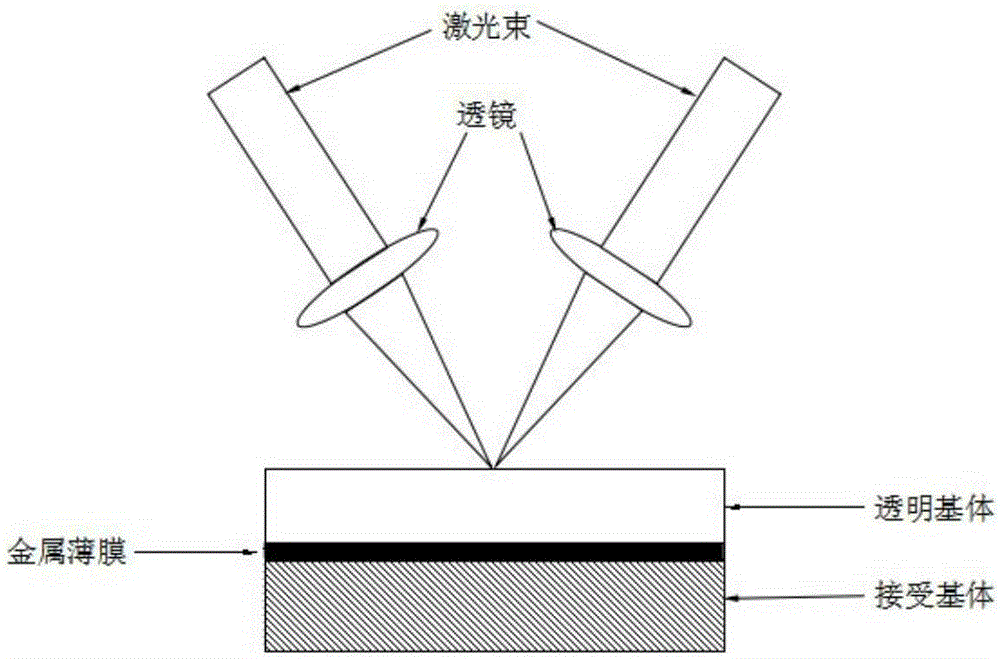

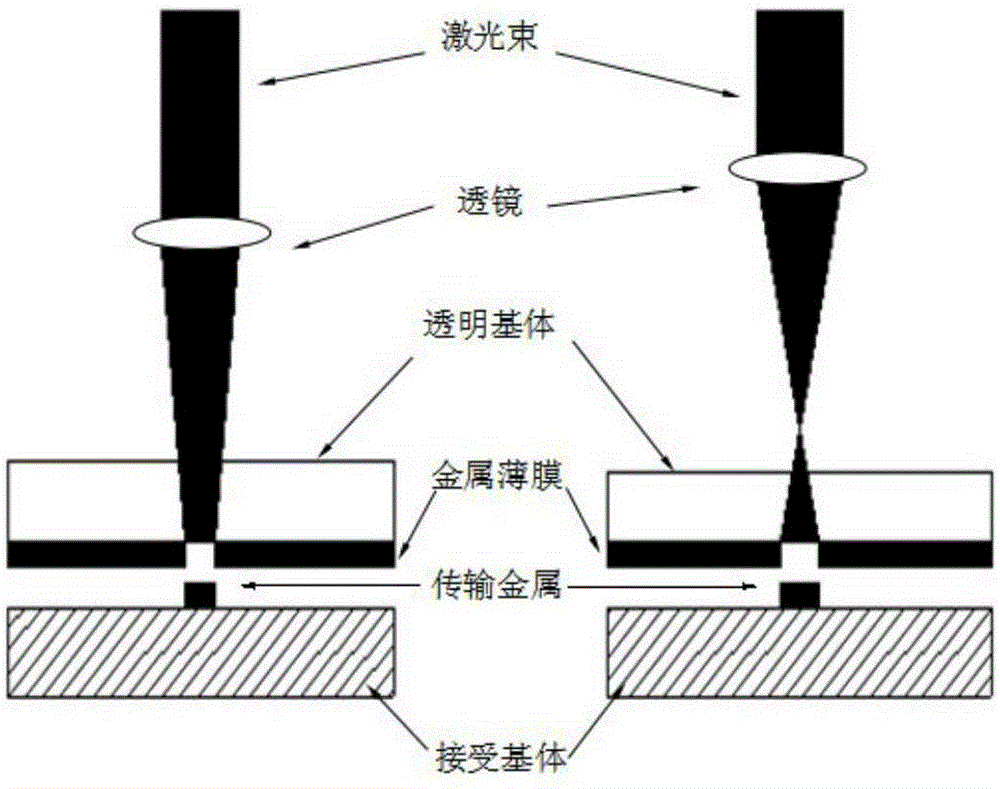

Method used

Image

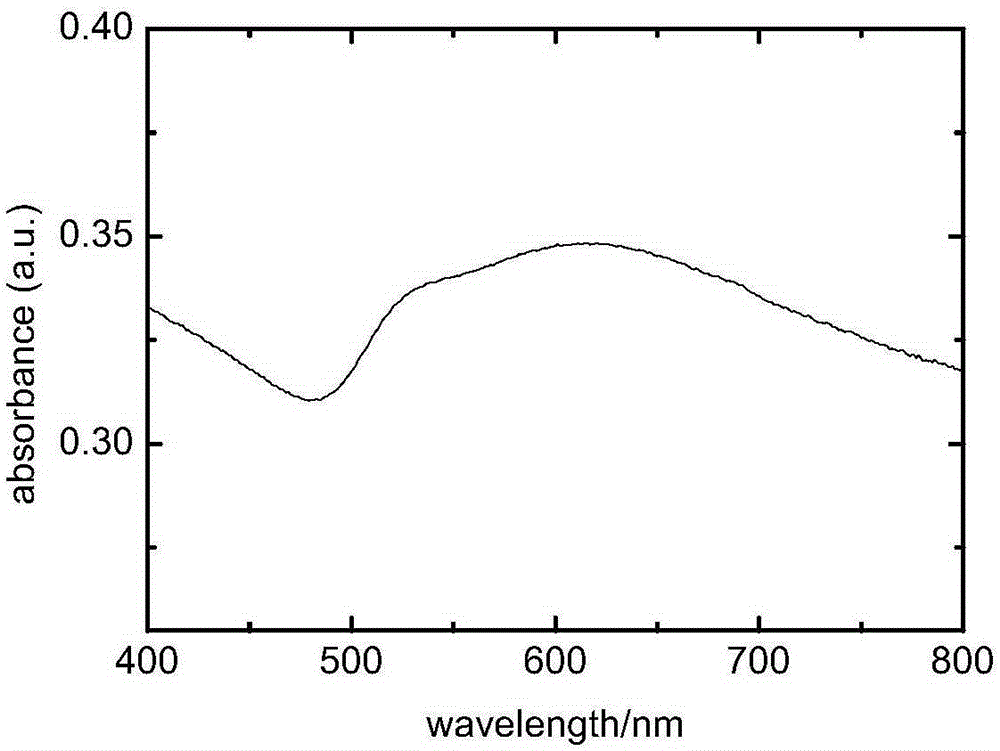

Examples

Embodiment 1

[0031] A method for preparing an ordered microstructure of gold nanoparticles, comprising the following steps:

[0032] Step 1. Ultrasonic cleaning of a transparent substrate with pure water, detergent, acetone and ethanol for 10 minutes, and then drying with high-pressure nitrogen with a purity of 99.9%; the ultrasonic frequency of ultrasonic cleaning is 20KHZ, and the power is 700W;

[0033] Step 2. Prepare the metal film by magnetron sputtering process. The working conditions are: first vacuum the magnetron sputtering apparatus to less than 5Pa, then turn on the molecular pump, and turn on the high vacuum gauge after 50 minutes to check the vacuum in the sputtering vacuum chamber. degree until the vacuum degree in the sputtering vacuum chamber is less than 4×10 -4 Pa; use argon and oxygen with a volume ratio of 100:1 as the background gas, place the transparent substrate on the aluminum dielectric target to be sputtered, and then open the background gas valve switch to feed...

Embodiment 2

[0037] A method for preparing an ordered microstructure of gold nanoparticles, comprising the following steps:

[0038] Step 1. Ultrasonic cleaning of a transparent substrate with pure water, detergent, acetone and ethanol for 10 minutes, and then drying with high-pressure nitrogen with a purity of 99.9%; the ultrasonic frequency of ultrasonic cleaning is 30KHZ, and the power is 800W;

[0039] Step 2, using the electron beam evaporation process to prepare the metal thin film, the method is: put the copper film material in the crucible of the electron beam evaporation equipment, put the transparent substrate on the heating electric furnace of the electron beam evaporation equipment, and make the transparent substrate Located 25cm directly above the crucible; in a vacuum of 5×10 -3 Coating under Pa, the temperature of the transparent substrate is controlled at 50°C, the electron beam is adjusted to minimize the spots on the copper film material, the beam current value is control...

Embodiment 3

[0043] A method for preparing an ordered microstructure of platinum nanoparticles, comprising the following steps:

[0044] Step 1. Ultrasonic cleaning of a transparent substrate with pure water, detergent, acetone and ethanol for 10 minutes, and then drying with high-pressure nitrogen with a purity of 99.9%; the ultrasonic frequency of ultrasonic cleaning is 25KHZ, and the power is 800W;

[0045] Step 2. Prepare the metal film by magnetron sputtering process. The working conditions are: first vacuum the magnetron sputtering apparatus to less than 5Pa, then turn on the molecular pump, and turn on the high vacuum gauge after 50 minutes to check the vacuum in the sputtering vacuum chamber. degree until the vacuum degree in the sputtering vacuum chamber is less than 4×10 -4 Pa; use argon and oxygen with a volume ratio of 100:1 as the background gas, place the transparent substrate on the aluminum dielectric target to be sputtered, and then open the background gas valve switch to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com