A double-absorbing layer solar spectrum selective absorption coating and its preparation method

A technology of solar spectrum and absorption coating, which is applied in solar thermal devices, solar thermal power generation, chemical instruments and methods, etc., can solve the problem that the process stability has a great influence on the coating performance, the manufacturing process is complicated, and the coating has a high absorption rate. and other problems, to achieve the effects of excellent spectral selectivity, low requirements for required conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

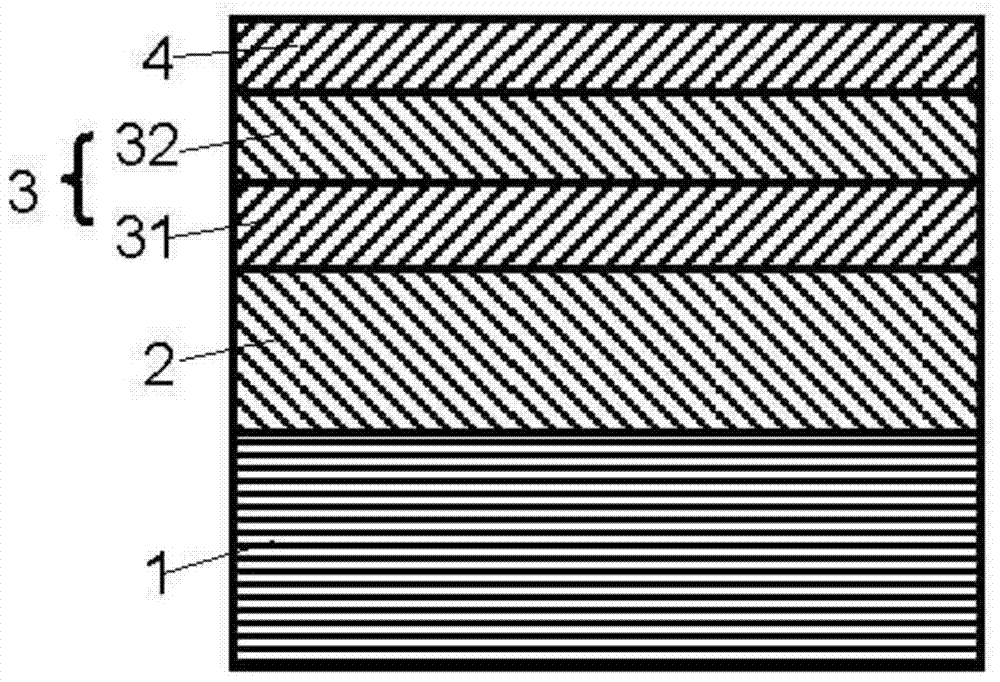

[0035] A method for preparing a solar spectrum selective absorption coating with a double-absorbing layer, comprising the following steps: cleaning a base layer; preparing an infrared reflection layer on the base layer by a coating method; preparing a double-layer coating on the infrared reflection layer by a coating method. Structural absorption layer; an anti-reflection layer is prepared on the double-structure absorption layer by coating method; the absorption layer includes a high refractive index absorption sublayer and a low refractive index absorption sublayer from bottom to top, and the high refractive index Both the absorbing sublayer and the low refractive index absorbing sublayer are sequentially prepared by coating method.

[0036] Another embodiment of the present invention proposes a double-absorbing layer solar spectrum selective absorption coating. Compared with the above-mentioned embodiment, the material of the base layer is glass, aluminum, copper or stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com