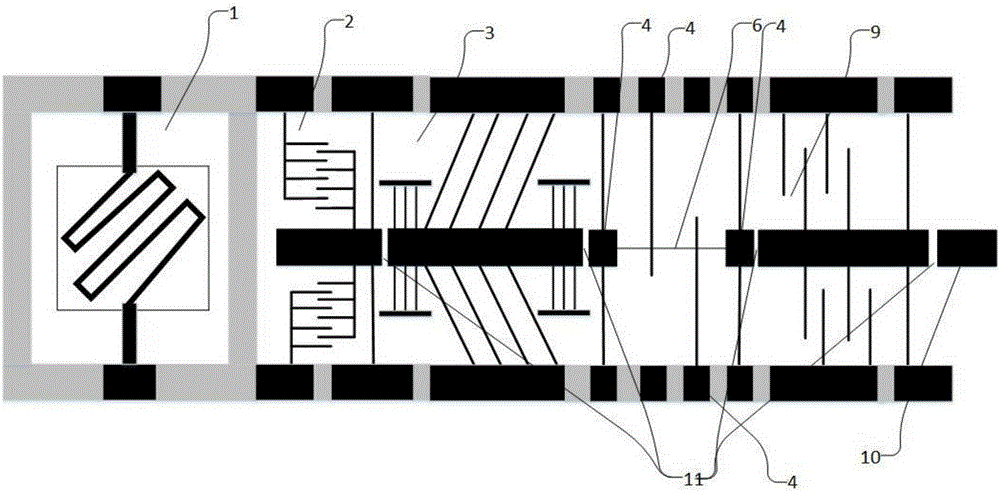

Nanowire huge piezoresistive characteristic measuring device and manufacturing method thereof

A measurement device and nanowire technology, applied in the field of micro-nano electromechanical systems, can solve problems such as influence and reduce measurement accuracy, and achieve the effects of easy research, improved accuracy, and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

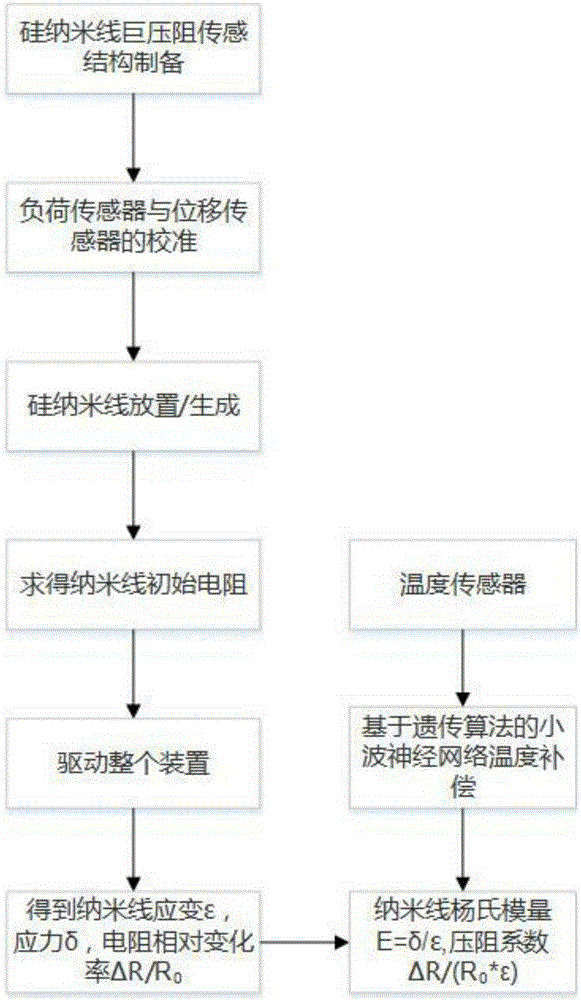

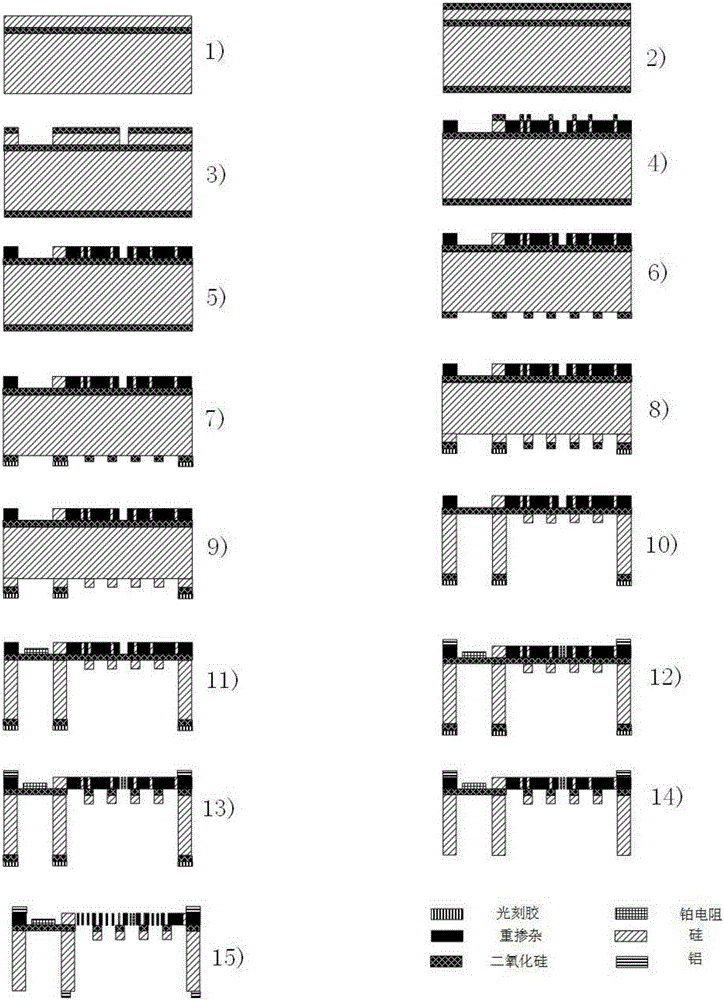

[0056] Such as image 3 As shown, a preparation method of a nanowire giant piezoresistive characteristic measuring device, the specific steps of the method:

[0057] 1) Choose an SOI silicon wafer with a top silicon layer of 25 μm, a buried oxide layer of 2 μm, and a bottom silicon layer of 300 μm, and place the silicon wafer in a mixed solution of acetone, hydrogen peroxide, and concentrated sulfuric acid for ultrasonic cleaning, and then repeatedly clean it with deionized water; then Put the cleaned silicon chip into the diluted HF solution to react to remove the oxide layer on the surface of the silicon chip;

[0058] 2) Deposit 1 μm SiO on the top and bottom silicon of the SOI wafer by LPCVD technology 2 oxide layer;

[0059] 3) Etch the top layer SiO by RIE (reactive ion etching) technology 2 The oxide layer forms the platinum resistance area; the platinum resistance area is etched by DRIE (deep reactive ion etching) technology;

[0060] 4) Etching the top layer SiO b...

Embodiment 1

[0075] Example 1: Silicon nanowires with silver

[0076] The experimental process for the preparation of Si nanowires is as follows: firstly, 2% HF solution (HF:H 2 O=1:50) to clean the Si wafer for 3 minutes to remove the natural oxide layer on the surface of the Si wafer; then, put the silicon wafer into a mixed solution of acetone, hydrogen peroxide and concentrated sulfuric acid for ultrasonic cleaning, and then deionized water Repeated cleaning; then use a vacuum evaporation coating machine to evaporate high-purity Au, and deposit a certain thickness of metal catalyst on the surface of the Si substrate; finally, place the sample of the deposited metal catalyst in the quartz tube of the automatic temperature-controlled tubular oxidation furnace, Under the protective atmosphere with a temperature of 800-1100° C. and a certain flow rate, high-temperature annealing is performed to grow Si nanowires. Treat the oxide film on the nanowires with hydrofluoric acid, passivate the ...

Embodiment 2

[0077] Example 2: SiGe Radial Heterojunction Nanowires

[0078] Gold nanoclusters were deposited on an oxidized silicon wafer and placed in a quartz tube furnace. At 450°C, using silane as a precursor gas, the silicon nanowire core grows at a growth rate of about 2 μm / min in the axial direction, and then uses silane and 100 ppm helium diborane as a precursor gas to deposit a p-type silicon shell, And at a radial growth rate of 10 nm / min. Then, under the condition of 380°C, the germanium nanowires were grown at an axial growth rate of 0.72um / min in 10% of the relevant argon gas, while the germanium shell was grown in the furnace at a growth rate of 10nm / min by changing the position and environment of the growth substrate. Radial velocity deposition. Nanowires of various core-shell structures, such as Si / Ge, Ge / Si, or Si / Ge / Si, Ge / Si / Ge, etc., can be completed by repeating the above process. Its process flow chart is as Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com